Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | RMIO-11C |

| Manufacturer | ABB |

| Product Category | Remote Multiplexed I/O Module |

| I/O Capacity | 16 digital inputs / 16 digital outputs |

| Input Type | 24 VDC wet/dry contact (sink/source) |

| Output Type | 24 VDC transistor (0.5A per channel) |

| Isolation | 1500 VAC channel-to-backplane |

| Update Rate | 5 ms (all points) |

| Communication | RS-485 Modbus RTU (2-wire) |

| Operating Temperature | -20°C to +70°C |

| Power Supply | 24 VDC (20.4–28.8 V), 2A max |

| Certifications | UL 508, CE, IEC 61131-2 |

| Enclosure Rating | IP20 (rack-mounted) |

| Diagnostic Features | Channel-level short-circuit detection |

Product Introduction

The ABB RMIO-11C is a robust remote I/O module designed for distributed control architectures within ABB’s Advant OCS and Symphony Plus ecosystems. Serving as a cost-effective field interface solution, this module multiplexes 16 discrete inputs and 16 solid-state outputs over a single RS-485 link, extending control capability to hazardous or space-constrained locations. As part of ABB’s legacy remote I/O portfolio, the RMIO-11C interfaces with MasterPiece 200 controllers via CI532 communication interfaces, enabling real-time monitoring of limit switches, solenoid valves, and motor starters in oil/gas and power generation applications.

Engineered for reliability in electrically noisy environments, the module features optical isolation and transient voltage suppression on all I/O channels. The ABB RMIO-11C operates as a slave device in multidrop configurations, supporting up to 32 devices per RS-485 segment with 1200m cable runs. Its compact form factor and DIN-rail mounting simplify deployment in substation control cabinets, conveyor control stations, and remote wellhead panels where centralized I/O is impractical.

Core Advantages and Technical Highlights

High-Density Field Interface: Consolidates 32 I/O points in 25mm DIN space with screw-terminal connectivity. Group isolation reduces wiring complexity versus discrete modules.

Noise Immunity: Optical isolation (1500VAC) and TVS diodes (6kV surge) protect against ESD events common in switchyards. Input filters reject <20µs transients.

Deterministic Scanning: 5ms guaranteed refresh rate ensures timely response for safety interlocks. Output state freeze on communication loss enhances fail-safe behavior.

Legacy Integration: Compatible with ABB’s S+ Engineering tools for configuration. Automatic address conflict detection prevents bus collisions.

Maintenance Diagnostics: Per-channel LED status indicators (green=active, red=fault). Short-circuit protected outputs auto-disengage during overloads.

Typical Application Scenarios

In coal handling plants, the ABB RMIO-11C monitors belt conveyor pull-cord switches across 500m transfer points. Its Modbus RTU interface reports blockages to Symphony Plus DCS while outputs trigger local alarms.

For water treatment chlorination systems, the module controls solenoid valves in Zone 2 hazardous areas. Output short-circuit protection prevents ignition risks, while IP20 enclosure allows cabinet mounting outside containment zones.

In turbine lube oil systems, RMIO-11C inputs detect low-pressure switches, with outputs commanding auxiliary pump startups within 10ms of primary pump failure.

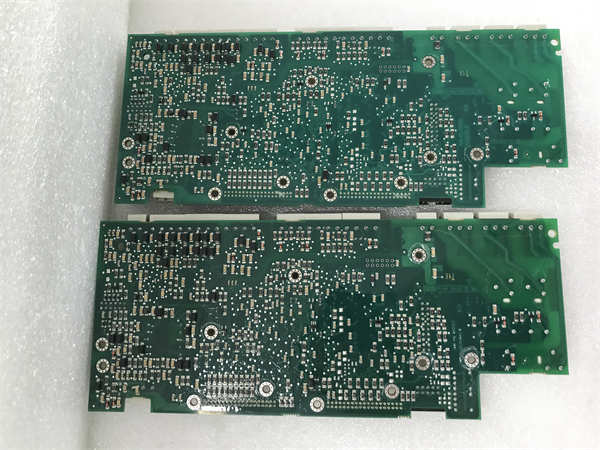

ABB RMIO-11C

Related Model Recommendations

CI532: Communication interface; links RMIO-11C to MasterPiece controllers

RMIO-21C: Analog variant (8AI/8AO) for mixed-signal applications

S500 I/O: Modern replacement with PROFIBUS/PROFINET support

TA521: Terminal board for field wiring consolidation

PM573-ETH: PLC for local logic processing of RMIO-11C data

SDCS-DIO-1: Digital I/O module for direct rack integration

Installation, Commissioning and Maintenance Instructions

Installation preparation: Verify grounding resistance <10Ω. Use shielded twisted-pair (120Ω impedance) for RS-485. Terminate bus ends with 120Ω resistors. Maintain 50mm clearance for heat dissipation. Configure node address via DIP switches before power-up.

Maintenance suggestions: Quarterly clean ventilation slots with dry air. Annually verify input threshold voltages (15–30VDC) and output load capacity. Replace if communication CRC errors exceed 5/hour. Store configuration files with S+ Engineering for rapid module swaps.

Service and Guarantee Commitment

ABB provides 15-year legacy support for RMIO-11C, including lifetime repair services. Reconditioned modules undergo 72-hour burn-in testing with full functional validation.

Global technical support offers configuration migration to ABB’s S500 I/O platform. Critical sites receive advance replacement units within 72 hours. Calibration certificates traceable to ISO/IEC 17025 standards provided with all repairs.