Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB RINT-5611C |

| Manufacturer | ABB |

| Product Category | Remote I/O Termination Interface |

| System Compatibility | Symphony® Plus S800 I/O |

| Channel Capacity | 16 channels (configurable) |

| Signal Types | Analog (4-20mA, RTD, TC), Digital (24V DC) |

| Isolation Voltage | 500 V AC (channel-to-channel/channel-to-system) |

| Connection Interface | Spring-clamp terminals |

| HART Support | Yes (7kHz FSK modulation) |

| Operating Voltage | 24 V DC ±10% (redundant inputs) |

| Power Consumption | 1.5 W (typical) |

| Operating Temperature | -40°C to +70°C |

| Environmental Rating | IP20 (module), IP54 (with cover) |

| Certifications | UL 61010-1, ATEX Zone 2, SIL 2 (IEC 61508) |

| MTBF | >250,000 hours (IEC 61709) |

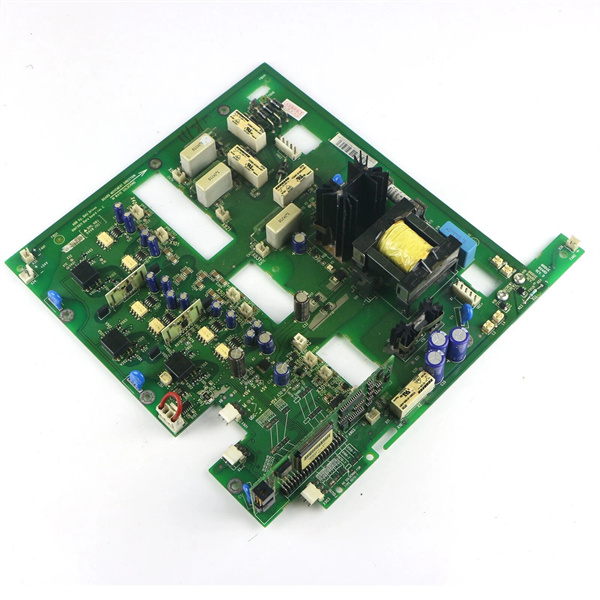

ABB RINT-5611C

Product Introduction

The ABB RINT-5611C is a high-density termination interface unit designed for ABB’s S800 Remote I/O system within Symphony® Plus DCS installations. Serving as the critical junction between field wiring and electronic I/O modules, this versatile termination unit simplifies signal conditioning and wiring management for both analog and digital signals. The ABB RINT-5611C features configurable channel assignments that allow mixed signal types within the same unit, eliminating the need for separate termination panels and reducing cabinet space requirements by up to 40%.

Engineered for extreme environments, the ABB RINT-5611C incorporates 500V channel-to-channel isolation to prevent ground loops and signal interference in electrically noisy industrial settings. Its integrated HART passthrough capability enables bidirectional communication with smart field instruments without additional hardware. As an essential component in distributed control architectures, the ABB RINT-5611C ensures signal integrity from field sensors to controllers while providing test points for maintenance without disrupting live processes.

Core Advantages and Technical Highlights

Universal Signal Handling: Unique switch-selectable per-channel configuration supports thermocouples, RTDs, 4-20mA signals, and 24V digital I/O on the same termination unit. Automatic cold junction compensation (CJC) with ±0.3°C accuracy.

Enhanced Signal Integrity: Triple-shielded design with isolated power domains achieves >120dB common-mode rejection. Active noise filtering adapts to variable-frequency drive interference.

Maintenance Efficiency: Integrated test switches allow channel isolation and current injection without disconnecting field wiring. Polarity reversal detection alerts to wiring errors during commissioning.

Safety Integration: SIL 2-certified signal conditioning paths with hardware-based overcurrent protection (30V/250mA limit). Conformal-coated PCB withstands 95% humidity and corrosive atmospheres.

Wiring Optimization: Color-coded spring-clamp terminals with dual-level access simplify terminations. Integrated disconnect switches enable module replacement without field wiring disturbance.

Environmental Robustness: Zinc-nickel plated contacts resist sulfurization in wastewater plants. Vibration-proof design maintains connection integrity under 5g continuous vibration.

Typical Application Scenarios

In chemical batch reactors, the ABB RINT-5611C terminates RTDs monitoring jacket temperatures alongside 4-20mA pressure transmitters. Its channel isolation prevents cross-talk between corrosive process streams, while HART passthrough validates control valve position feedback during catalyst injection cycles.

For power plant turbine halls, the unit interfaces vibration probes (-40°C rated) with redundant analog inputs. The ABB RINT-5611C‘s 500V isolation protects the DCS from ground potential rises during generator faults. Test switches enable monthly calibration checks without turbine shutdown.

In pharmaceutical freeze-dryers, the termination unit’s ATEX certification allows installation in Zone 2 areas. RTD channels maintain 0.1°C measurement stability for critical shelf temperature control, with integrated disconnects facilitating FDA-required calibration traceability.

Related Model Recommendations

ABB RINT-5612C: Enhanced version with PROFIBUS PA interface

ABB TA521: Standard termination unit for non-configurable I/O

ABB EI813F: Analog input module pairing with RINT-5611C

ABB SD821: Digital input module for same cabinet

ABB SA801: Base unit for S800 I/O mounting

ABB NTAI06: Temperature transmitter for remote termination

ABB ZMU01: Power supply for redundant systems

ABB DSTT02: Test tool for RINT-5611C diagnostics

ABB RINT-5611C

Installation, Commissioning and Maintenance Instructions

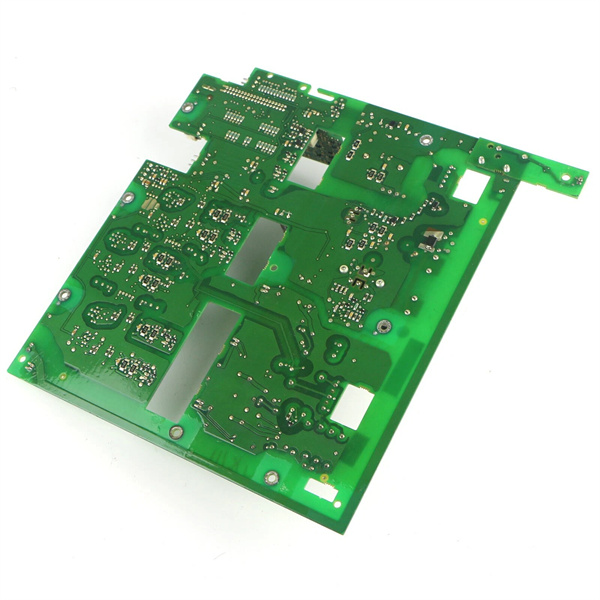

Installation Preparation: Verify DIN rail alignment (±0.5mm tolerance). Use 600V-rated shielded cables (AWG 18-22). Maintain 15mm clearance between field wiring groups. Pre-configure channel types via DIP switches before wiring. Ground shield at marshalling cabinet only.

Maintenance Suggestions: Perform annual torque checks on terminal blocks (0.6 N·m). Clean contacts with electronic-grade isopropyl alcohol during outages. Monitor “Isolation Resistance” in diagnostics – values <10MΩ indicate moisture ingress. For HART instruments:

Verify pass-through voltage >19V DC

Check termination impedance (250Ω ±1%)

Replace units showing persistent “Open Wire” alarms on multiple channels.

Service and Guarantee Commitment

ABB provides a 60-month warranty for the RINT-5611C, covering all material and workmanship defects. Our global support includes:

24/7 technical assistance via ABB ControlCare®

On-site troubleshooting within 8 business hours

Complimentary wiring diagram validation

Lifetime firmware updates with backward compatibility

Extended product lifecycle commitment until 2035

Calibration services with ISO/IEC 17025 certification

All units undergo 100% dielectric testing at 2.3kV AC and operational validation across temperature extremes (-40°C to +85°C). SIL 2 certification includes TÜV Rheinland validation reports.