Description

Key Technical Specifications

- Model Number: RET543AM240AAAA

- Manufacturer: ABB Power Grids Division

- Protection Functions: Transformer differential protection, overcurrent (50/51), earth fault (59N/64N), overvoltage (59)/undervoltage (27), thermal overload (49), circuit breaker failure (50BF)

- Communication Protocols: IEC 61850 (GOOSE, Sampled Values), Modbus RTU/TCP, DNP3.0, IEC 60870-5-104

- Power Supply: 24VDC ±10% (19.2-26.4VDC); 15W typical power consumption

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Isolation Rating: 2kV AC (input circuits to control/communication circuits); 5kV AC (power circuits to ground)

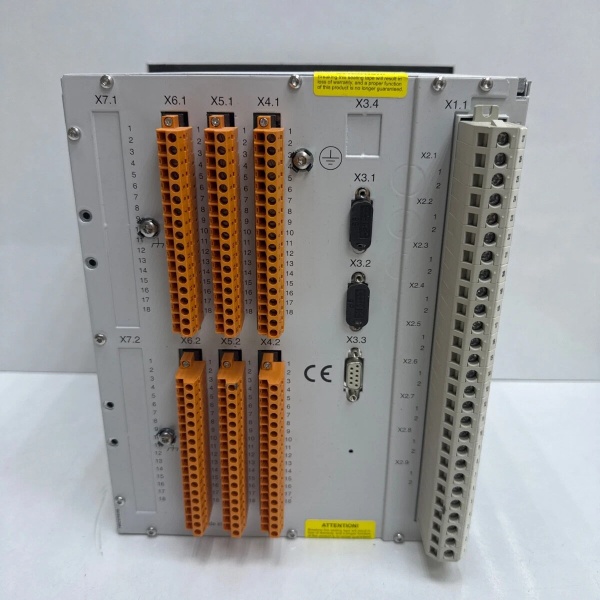

- I/O Configuration: 8 digital inputs (DI), 4 digital outputs (DO); 4 analog inputs (AI) for CT/VT signals

- CT/VT Ratings: CT: 1A/5A (configurable); VT: 100V/220V (line-line)

- Display & HMI: 3.5” color LCD, 4 tactile buttons, LED status indicators

- Certifications: CE, UL 10C, IEC 61850-3/5, IEC 60255-1, RoHS 2.0, ATEX Zone 2

- Compatibility: ABB MicroSCADA Pro, third-party SCADA systems, IEC 61850-compliant substation devices

- Memory & Logging: 10,000 event logs, 500 fault records (with waveform capture)

ABB RET543AM240AAAA

Field Application & Problem Solved

In power utilities and industrial substations—transformer yards, generator plants, renewable energy (solar/wind) grid connections—equipment protection is non-negotiable. Generic protective relays fail two critical tests: precise, multifunctional protection for transformers/generators and seamless integration with modern substation automation systems (SAS). A Midwest utility lost $520k in a 6-hour outage when a generic relay failed to detect a transformer winding fault, leading to catastrophic damage. Legacy relays also lack IEC 61850 compliance: a Texas industrial plant spent $40k on external gateways to connect old relays to their SAS, causing 2 hours of monthly downtime from communication lags.

You’ll find this relay protecting: 11kV-33kV distribution transformers in utility substations, industrial generator sets (5-50MW), and solar/wind farm grid-tie transformers. Its core value is multifunctional protection + IEC 61850 native integration + rugged utility-grade design. The built-in transformer differential logic eliminates the need for multiple single-function relays, while IEC 61850 GOOSE support enables fast (<10ms) inter-relay communication—critical for substation-wide fault coordination. For a California solar farm, the relay’s -25°C to +70°C operating range withstood desert heat and winter cold, unlike generic relays that required climate-controlled enclosures (adding $15k per substation).

Installation & Maintenance Pitfalls (Expert Tips)

- CT/VT Wiring: Match Polarity Exactly: Rookies reverse CT secondary wiring, causing differential protection misoperation. A Florida utility’s transformer relay tripped incorrectly during normal load until polarity was corrected. Follow ABB’s color-coded diagram (CT: red=positive, black=negative) and use a polarity tester to verify—incorrect wiring voids protection integrity.

- IEC 61850 GOOSE Configuration: Sync Dataset Names: Mismatched GOOSE dataset names between relays cause communication failures. An Ohio industrial plant’s circuit breaker failure protection didn’t activate until GOOSE datasets were standardized in the SAS. Use ABB’s Relion Engineer software to align dataset names and test GOOSE message latency (<10ms).

- Firmware Mismatch with SAS: Outdated relay firmware (pre-v7.0) with IEC 61850-9-2 Sampled Values causes data corruption. A Pennsylvania utility’s fault records were incomplete until the RET543AM240AAAA was updated to v8.1. Always verify firmware compatibility with the SAS (check ABB’s compatibility matrix) before commissioning.

- Grounding: Dedicated Substation Ground Grid: Sharing the relay’s ground with non-critical equipment introduces noise, leading to false overcurrent trips. A Texas wind farm’s relays tripped weekly until connected to the substation’s dedicated ground grid (ground resistance <0.5Ω). Route ground wires separately from power cables and avoid daisy-chaining grounds.

- Test All Protection Functions Post-Installation: Rookies skip testing niche functions (e.g., circuit breaker failure) during commissioning. A Midwest utility missed a faulty 50BF function, leading to a near-miss when a breaker failed to open during a fault. Use ABB’s test kit (e.g., 1SVR730700R0000) to simulate all fault types and verify relay response times.

ABB RET543AM240AAAA

Technical Deep Dive & Overview

The ABB RET543AM240AAAA is a utility-grade digital protective relay engineered to monitor and protect power transformers, generators, and distribution assets. At its core, a 32-bit digital signal processor (DSP) samples CT/VT inputs (up to 1kHz) and executes pre-configured protection logic—detecting faults (short circuits, earth faults, overloads) and triggering trip outputs to isolate faulty equipment within 10ms. The relay’s multifunctional design integrates 8+ protection functions, eliminating the need for multiple single-purpose relays in substation cabinets.

Unlike generic relays, it natively supports IEC 61850 (GOOSE for fast peer-to-peer communication, Sampled Values for digital CT/VT integration), enabling seamless integration with modern substation automation systems. This eliminates latency from external protocol converters and simplifies engineering via standard IEC 61850 data models. The relay’s rugged design includes a conformal-coated PCB, wide operating temperature range, and 5kV AC isolation—critical for harsh substation environments with electrical noise, dust, and temperature extremes.

What sets it apart is its asset management capabilities: it logs 10,000 events and 500 fault waveforms, providing actionable data for predictive maintenance (e.g., detecting incipient transformer winding faults). Integration with ABB’s Relion Engineer software allows remote configuration, firmware updates, and fault analysis—reducing on-site maintenance time by 30%. For utilities and industrial plants where unplanned downtime costs $100k+/hour, this relay isn’t just a protective device—it’s a critical component of a reliable, efficient power asset management system.