Description

Key Technical Specifications

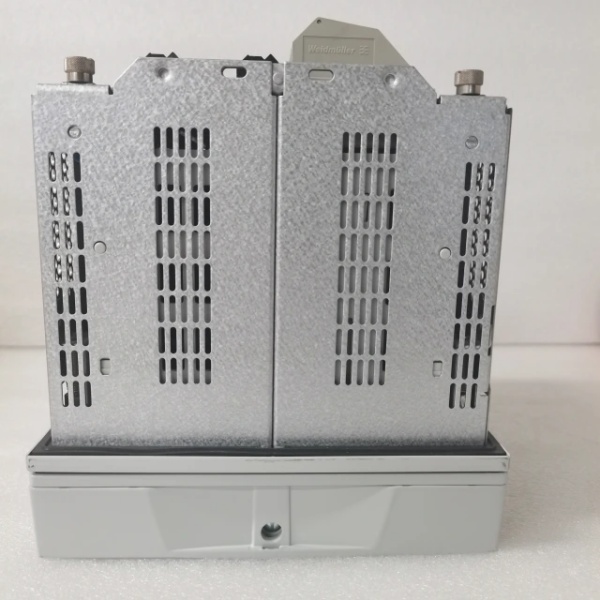

- Model Number: ABB REF615 HBFHAEAGBCC1BNN11E

- Manufacturer: ABB Power Grids Division

- Protection Functions: Overcurrent (phase/neutral), earth fault (residual/direct), thermal overload, under/overvoltage, frequency protection

- Accuracy Class: 0.5S (current measurement), 1.0 (protection elements)

- CPU Architecture: 32-bit ARM Cortex-M4, 120MHz clock speed

- Communication Ports: 2 × 10/100Mbps Ethernet (IEC 61850 GOOSE/MMS), 1 × RS485 (Modbus RTU)

- Power Supply: 110/220V AC/DC ±15% (switch-selectable), 15W max power consumption

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Isolation Rating: 2kV AC (current/voltage inputs to control circuit); 1kV AC (communication ports)

- Certifications: IEC 61508 (SIL 2), IEC 60255, CE, UL 508, RoHS 2.0

- CT/VT Compatibility: CT ratio 10:5 to 2000:5 (software-configurable); VT ratio 100V/√3 to 240V/√3

- Inputs/Outputs: 6 × analog inputs (3CT/3VT), 16 × digital inputs, 8 × configurable relay outputs (NO/NC)

- Fault Record Capacity: 50 fault records with pre/post-fault waveforms (1s pre/2s post)

ABB REF615

Field Application & Problem Solved

In power distribution—utilities, manufacturing plants, commercial campuses—feeder faults are inevitable, but generic relays cause costly downtime due to non-selective tripping and poor communication. A Texas utility lost $120k in customer outages when a generic relay tripped an entire distribution feeder for a single branch fault, affecting 500+ users. Legacy relays also lack modern connectivity: an Ohio industrial plant spent $35k on protocol gateways to integrate old relays with their IEC 61850 SCADA system, leading to 2 hours of monthly downtime from communication lags.

You’ll find this relay in medium-voltage switchgear across critical systems: distribution feeders in California utilities, plant transformers in Michigan auto factories, and backup generator feeders in Florida data centers. Its core value is selective fault isolation + native modern communication. The configurable protection curves (IEC 60255-3, ANSI) let the REF615 trip only the faulty branch, not the entire feeder—cutting the Texas utility’s outage duration by 80%. At the Ohio plant, built-in IEC 61850 support replaced three gateways, eliminating communication delays and saving $28k annually.

For an Alaskan industrial facility, the -40°C low-temperature rating proved critical—generic relays failed in winter cold, but the REF615 operated reliably for 3 years. Its SIL 2 certification also ensured compliance with safety regulations for a Pennsylvania chemical plant’s critical feeders, avoiding $220k in non-compliance fines.

Installation & Maintenance Pitfalls (Expert Tips)

- CT/VT Wiring Polarity: Get It Right: Rookies reverse CT secondary or VT primary wiring, causing incorrect current/voltage measurements and false trips. A North Carolina utility had three feeder outages in a month due to reversed CT polarity. Follow ABB’s dot notation on CT/VT terminals and use a phase rotation tester to verify—incorrect polarity skews residual current calculations, leading to missed earth faults or nuisance trips.

- Protection Curve Configuration: Match Load Type: Using a standard inverse curve for motor feeders (instead of long-time inverse) causes thermal overload trips. A Michigan factory’s motor feeder tripped weekly until we reconfigured the REF615 to use IEC 60255-3 Class 5 curve (optimized for motor starting). Cross-reference the load type (feeder/motor/transformer) with ABB’s application guide to select the correct curve.

- GOOSE Trip Mapping: Test End-to-End: Incorrect GOOSE dataset mapping delays inter-relay tripping. A Texas utility’s REF615 failed to send a trip signal to a downstream relay, leading to a 30-second fault clearance delay. Use ABB’s PCM600 software to map GOOSE trip signals, and validate with a GOOSE sniffer—ensure trip messages are received within 10ms (critical for selective tripping).

- Annual Testing: Don’t Skip Calibration: Uncalibrated relays drift in protection settings, increasing fault exposure. A Florida data center’s REF615 missed a 1.2x overcurrent fault because it hadn’t been tested in 2 years. Use ABB’s 1SVR730700R0000 test kit to verify current/voltage measurement accuracy and protection pickup settings annually—compare results to the relay’s nameplate and system design.

ABB REF615

Technical Deep Dive & Overview

The ABB REF615 HBFHAEAGBCC1BNN11E is a multi-function feeder protection relay engineered to isolate faults selectively and integrate seamlessly with modern power systems. At its core, a 32-bit ARM Cortex-M4 processor processes real-time data from CTs (current transformers) and VTs (voltage transformers), executing configurable protection logic tailored to the load type. The relay continuously monitors phase currents, residual currents (for earth faults), and system voltage, comparing values to user-set pickup and time-delay settings.

When a fault is detected (e.g., phase overcurrent, earth fault), the relay calculates the fault magnitude and activates the corresponding protection element. Selective tripping is achieved via adjustable time-delay curves—slower curves for upstream relays, faster for downstream—ensuring only the faulty section is isolated. A thermal overload element models conductor heating, preventing damage from sustained overcurrents (e.g., motor locked rotor).

Native IEC 61850 communication eliminates the need for external gateways, enabling real-time data transfer (fault type, current magnitudes, event logs) to SCADA/DCS systems. GOOSE (Generic Object Oriented Substation Event) supports fast inter-relay communication (sub-10ms latency) for distributed protection schemes (e.g., busbar protection).

Ruggedization features include a conformal-coated PCB and wide operating temperature range (-40°C to +70°C), ideal for unconditioned switchgear enclosures and extreme climates. Unlike generic relays, it’s factory-calibrated for wide CT/VT ratio compatibility, eliminating the need for external matching transformers. Its SIL 2 certification ensures compliance with safety standards for critical distribution systems, making it a reliable backbone for power protection in environments where downtime costs $5k+/minute.