Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

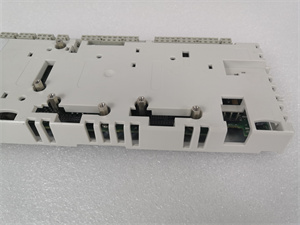

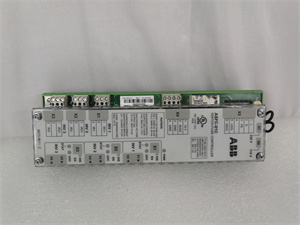

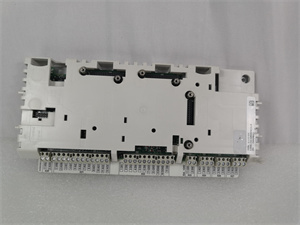

| Product Model | RDCU-12C |

| Manufacturer | ABB |

| Product Category | Relay Digital Control Unit |

| Input Channels | 12 optically isolated digital inputs |

| Input Voltage Range | 24-250 V DC/AC |

| Response Time | ≤3 ms |

| Output Channels | 8 Form C relay outputs (5A @ 250V AC) |

| Contact Rating | 5A resistive (AC1)/2A inductive (AC15) |

| Isolation Voltage | 4000 V AC (input-output) |

| Power Supply | 24-48 V DC/AC (±20%) |

| Operating Temperature | -40°C to +85°C |

| Communication Interface | RS-485 (Modbus RTU) |

| Certifications | IEC 61850-3, IEEE 1613, UL 508 |

| Enclosure Rating | IP40 (module)/IP20 (terminals) |

ABB RDCU-12C

Product Introduction

The ABB RDCU-12C is a hardened digital control relay unit designed for mission-critical switching operations in power automation systems. As a key component of ABB’s Relion® protection and control portfolio, this module provides deterministic logic execution for grid substations, generator protection, and industrial power management. The RDCU-12C integrates 12 high-immunity input channels and 8 fail-safe relay outputs within a compact footprint, executing custom logic schemes without requiring external PLCs.

Engineered for IEC 61850-3 compliance, the ABB RDCU-12C operates reliably in electrically noisy environments like switchgear cabinets, with 100 kV/μs transient immunity and 4 kV galvanic isolation. Its non-volatile memory stores configuration parameters during power loss, while the embedded real-time clock timestamps all events for sequence-of-events (SOE) recording. The unit serves as a distributed intelligence node within ABB’s Relion 670 Series, enabling decentralized control decisions with ≤1 ms deterministic latency.

Core Advantages and Technical Highlights

Ultra-Fast Logic Execution:

Hardware-based logic solver processes 128 digital signals in ≤1 ms, outperforming software-based PLCs. Dedicated watchdog circuitry ensures fail-safe output states during disturbances.

Extreme Environmental Tolerance:

Operates at -40°C without heaters and withstands 95% humidity. Conformal coating protects against corrosive sulfur gases in switchyards. Meets Class C2 (salt fog) and Class S2 (pollution) per IEC 60068.

Cybersecurity Hardening:

Secure firmware update with SHA-256 authentication. Write-protected configuration memory prevents unauthorized changes. Physical key switch for local lockout.

Simplified Engineering:

ABB PCM600 software enables drag-and-drop logic design using standard IEC 61131-3 function blocks. Pre-tested application templates for auto-reclosing, load shedding, and interlocking.

Diagnostic Visibility:

Per-channel LED status indicators. Built-in health monitoring reports contact erosion, coil resistance drift, and insulation degradation.

Typical Application Scenarios

In electrical substations, the ABB RDCU-12C executes breaker failure protection (BFP) logic, initiating backup tripping within 3 ms of primary relay failure. Its -40°C rating ensures reliability in Arctic installations.

Wind turbine control cabinets deploy the module for pitch system safety interlocks, where hardware-based overspeed logic bypasses software layers during grid faults. RS-485 connectivity feeds turbine data to SCADA via Modbus.

Industrial cogeneration plants use the RDCU-12C for load sequencers, shedding non-critical loads during underfrequency events. The 4 kV isolation withstands voltage surges from vacuum breaker switching.

Related Model Recommendations

REC670: Bay controller for RDCU-12C integration in protection schemes.

REF615: Feeder protection relay with direct logic communication.

SACE Tmax XT: Circuit breakers with RDCU-12C interface capability.

DDAI-01: 16-channel digital input expansion module.

CM-UFD: Universal firmware downloader tool.

1VCP000850: DIN rail power supply (24 VDC/5A).

RER670: Generator protection relay for coordinated control.

ABB RDCU-12C

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify clearance ≥25 mm above/below module for convection cooling. Ground mounting plate to ≤0.1 Ω using 4 mm² copper wire. Use shielded twisted-pair cables for inputs (max 100 m). Required tools: Torque screwdriver (0.4 N·m), PCM600 V2.12+.

Maintenance Suggestions:

Semi-annually: Test input response using ABB RIO-01 test set. Verify output contact resistance (<100 mΩ). Every 5 years: Calibrate timing via pulsed inputs. Replace after 100,000 operations or if contact voltage drop exceeds 200 mV. Store configuration files on SD card (slot on front).

Service and Guarantee Commitment

ABB provides a 10-year design life warranty for the RDCU-12C, covering premature contact wear and component failure. Global support includes:

24/7 protection engineer hotline

On-site troubleshooting within 24 hours for critical grid applications

Lifetime firmware security updates

Extended service plans offer contact erosion analytics through ABB Ability™ Asset Performance Management. All units undergo 500-operation endurance testing and 10 kV impulse voltage verification before shipment.