Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

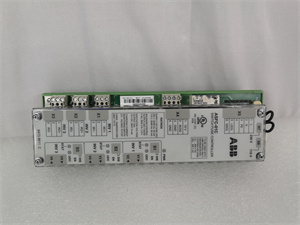

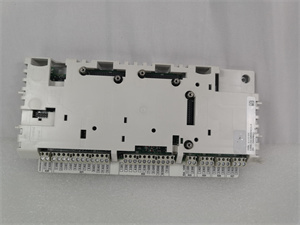

| Product Model | ABB RDCU-12C |

| Manufacturer | ABB |

| Product Category | Remote I/O Control Unit |

| Input Voltage | 24V DC (18-32V range) |

| Power Consumption | 8W typical, 12W max |

| Processor | 32-bit RISC processor |

| Memory | 64MB RAM, 128MB Flash |

| Digital I/O | 12 configurable channels |

| Analog Inputs | 4 channels (0-10V/4-20mA) |

| Communication Ports | 2x Ethernet (10/100 Mbps), 1x RS-485 |

| Protocol Support | Modbus TCP, PROFINET, OPC UA |

| Operating Temp | -40°C to +70°C |

| Protection Rating | IP65 (NEMA 4X) |

| Certifications | UL, CE, IEC 61131-2, Class 1 Div 2 |

RDCU-12C.

Product Introduction

The ABB RDCU-12C is a rugged remote distributed control unit designed for industrial automation applications requiring decentralized control. As part of ABB’s advanced control system portfolio, this compact yet powerful unit brings intelligence to the field level, reducing wiring costs and improving system reliability.

Engineered for harsh environments, the ABB RDCU-12C combines robust hardware with flexible software configuration to handle both discrete and analog signal processing. Its IP65-rated enclosure makes it suitable for outdoor installations and industrial areas exposed to dust, moisture, and temperature extremes.

With its powerful 32-bit processor and multiple communication options, the ABB RDCU-12C serves as an ideal solution for remote monitoring and control applications in industries ranging from oil and gas to water treatment and renewable energy.

Core Advantages and Technical Highlights

Extreme Environment Operation:

The ABB RDCU-12C maintains reliable performance across a wide temperature range (-40°C to +70°C) and withstands vibration up to 5g, making it suitable for offshore platforms and mobile equipment.

Flexible I/O Configuration:

12 digital channels can be individually configured as inputs or outputs, while 4 analog inputs support both voltage and current signals without hardware changes.

Advanced Communication Capabilities:

Dual Ethernet ports enable daisy-chain connections and network redundancy, while built-in protocol conversion simplifies integration with existing SCADA and DCS systems.

Cybersecurity Features:

Secure boot mechanism, role-based access control, and encrypted communications meet IEC 62443 standards for industrial network security.

Local Intelligence:

The unit can execute control logic locally using IEC 61131-3 compliant programming, reducing dependence on central controllers and improving response times.

Powerful Diagnostics:

Built-in web server provides real-time monitoring of I/O status, communication health, and environmental conditions through any standard browser.

RDCU-12C.

Typical Application Scenarios

Oil & Gas Wellheads:

Remote monitoring of pressure and temperature sensors in distributed field installations, with control of emergency shutdown valves.

Water Pumping Stations:

Decentralized control of pumps and chlorination systems across municipal water networks.

Solar Power Plants:

String monitoring and inverter control in large-scale photovoltaic installations.

Conveyor Systems:

Distributed motor control and safety interlocking for long material handling systems.

HVAC Networks:

Monitoring and control of air handling units across commercial building complexes.

Related Model Recommendations

ABB RDCU-8C – Compact version with 8 digital I/O

ABB RDCU-16A – Expanded analog version (8 AI/4 AO)

ABB RDCU-GW – Protocol gateway version

ABB AC500 – Compatible PLC controller

ABB CP600 – HMI panel for local operation

ABB TB321 – Terminal block expansion

ABB CM-ENS – Ethernet network switch

Installation, Commissioning and Maintenance

Installation Guidelines:

Mount the ABB RDCU-12C using provided DIN rail clips or direct panel mounting. Maintain minimum 50mm clearance around ventilation slots. Use shielded cables for all I/O and communication connections with proper grounding.

Commissioning:

Configure I/O types and scaling using ABB’s Automation Builder software

Set communication parameters and network addresses

Download control logic (if applicable)

Verify signal integrity through built-in web interface

Test failover scenarios for redundant configurations

Maintenance:

Monthly inspection of enclosure seals

Quarterly verification of I/O calibration

Annual firmware updates

5-year replacement of internal backup battery

Periodic cleaning of ventilation areas in dusty environments

Service and Guarantee Commitment

ABB provides a 36-month warranty for the RDCU-12C, including:

24/7 global technical support

On-site commissioning assistance

Advanced replacement program

Firmware updates and security patches

Repair and recalibration services