Description

Key Technical Specifications

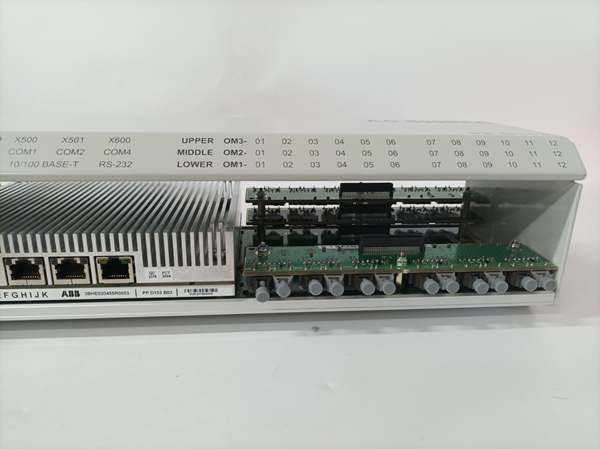

- Model Number: PPD113B03R2060 (ABB official: 3BHE023584R2060)

- Manufacturer: ABB Power Electronics Division (AC 800PEC Systems)

- Product Type: High-Performance Power Electronics Controller Module

- System Compatibility: ABB AC 800PEC (Power Electronics Controller) Platform

- Processor: 32-bit RISC processor (200+ MIPS), optimized for power electronics control algorithms

- Cycle Time: Down to 1µs for critical control loops (excitation, PWM generation)

- Memory: 128MB DDR3 RAM, 32MB Flash (programmable control logic storage)

- Isolation Rating: 2500VAC channel-to-channel, 3000VAC system-to-ground (meets IEC 61010-1)

- Communication Interfaces:

- Redundant Ethernet/IP (IEC 61850 compliant)

- Modbus TCP Slave/Master

- ABB Powerlink (real-time industrial Ethernet)

- Optical Modulebus (S800 I/O expansion)

- I/O Connectivity: Up to 32 analog inputs (16-bit resolution), 16 analog outputs, 64 digital I/O (configurable)

- Operating Temperature: -40°C to +70°C (extended industrial range for harsh environments)

- Vibration Resistance: Up to 5g (meets IEC 60068-2-6 for power plant/refinery environments)

- Power Supply: 24VDC ±10% (redundant input, 15W typical consumption)

- Mechanical: Standard 19″ rack mounting (3U height), hot-swappable design, aluminum alloy chassis

- Certifications: IEC 61850, IEC 61010-1, IEC 60068-2 (vibration/shock), UL 508 (industrial control equipment)

ABB PPD113B03R2060

Field Application & Problem Solved

In power generation and heavy industry, slow control response, poor signal integrity, and lack of redundancy cause catastrophic failures in power electronics systems. At a coal-fired power plant in Ohio, a legacy excitation controller with 10ms cycle time failed to stabilize generator voltage during a grid disturbance, causing a 2-hour shutdown and $210k in lost generation. At a Texas refinery, a non-redundant inverter controller failure halted crude distillation operations for 3.5 hours, costing $420k in lost production.

This PPD113B03R2060 solves these critical issues by delivering:

- Sub-microsecond control response: Stabilizes generator voltage/excitation within 1µs during grid transients

- Redundant communication: Eliminates single points of failure with dual Ethernet/IP & Modbus TCP ports

- Enhanced diagnostics: Prevents unplanned downtime with predictive maintenance alerts for power electronics components

- Industrial-grade durability: Conformal coating and extended temperature range handle harsh environments (dust, humidity, vibration)

You’ll find it in:

- Power Plants: Generator excitation control systems (coal, gas, nuclear) ensuring grid stability during load changes

- Petrochemical Refineries: High-voltage inverter control for large motors driving pumps/compressors in distillation units

- Heavy Industry: Static Var Compensators (SVC) maintaining power factor in steel mills and aluminum smelters

- Renewable Energy: Grid-tie inverters for wind/solar farms, ensuring compliance with grid codes

Installation & Maintenance Pitfalls (Expert Tips)

- Don’t Skip Conformal Coating Inspection: A technician at a Florida power plant installed a module with damaged conformal coating (from improper storage), leading to corrosion and failure during a humidity spike. Always inspect the PCB for cracks, bubbles, or peeling before installation—reject modules with visible damage.

- Redundant Power Connection is Mandatory: At an Illinois refinery, a single power supply failure caused a PPD113B03R2060 shutdown, halting a high-voltage pump. Connect both redundant 24VDC inputs to separate power sources (A/B bus) and verify voltage balance (within 0.5V) before commissioning.

- Cycle Time Optimization Prevents Instability: A rookie engineer set a 100µs cycle time for a generator excitation system, causing voltage oscillations. For excitation control, use 1-5µs cycle time for voltage regulation loops and 20-50µs for less critical monitoring functions—refer to AC 800PEC application notes for optimal settings.

- Grounding Separates Noise from Signals: Poor grounding at a Pennsylvania steel mill introduced 60Hz noise into control signals, causing SVC performance issues. Mount the module on a grounded DIN rail, connect the safety ground to the cabinet chassis, and keep power cables (≥10A) 30cm away from signal cables. Use shielded twisted-pair for analog signals, grounding only at the controller end.

- Hot-Swap Requires Proper Procedure: A technician at a Louisiana refinery removed a PPD113B03R2060 without disabling the power electronics, causing an IGBT overvoltage event. Always: 1) Disable the power electronics (via safety interlock), 2) Wait 5 seconds for capacitors to discharge, 3) Remove the module using the extraction handle (never pull by connectors).

- Firmware Version Matching Prevents Communication Loss: Mixing firmware versions (v3.2 and v4.1) in a redundant pair at a Texas power plant caused communication collisions. Ensure both primary and backup modules run the same firmware version (check via ABB Control Builder M software) before commissioning.

ABB PPD113B03R2060

Technical Deep Dive & Overview

The ABB PPD113B03R2060 is the brain of the AC 800PEC platform, engineered for high-speed, high-precision control of power electronics systems in harsh industrial environments. Unlike generic PLCs, it’s optimized for power conversion applications—excitation control, high-voltage inverters, SVCs—where microsecond-level response and signal integrity are non-negotiable.

Internally, it features a 32-bit RISC processor delivering 200+ MIPS, enabling real-time execution of complex control algorithms (PID, fuzzy logic, model predictive control) at cycle times down to 1µs. The module’s 2500VAC isolation maintains signal integrity in high-noise environments, while its redundant communication ports (Ethernet/IP, Modbus TCP) ensure seamless integration with DCS systems (System 800xA, Infi 90) and operator stations.

What makes it field-tough is its conformal-coated PCB (military-grade protection against dust, moisture, and chemical vapors) and extended temperature range (-40°C to +70°C), designed to withstand the thermal swings of power plant control rooms and refinery electrical enclosures. The hot-swappable design minimizes downtime during maintenance, while built-in diagnostics (current/voltage monitoring, temperature sensing, fault logging) enable predictive maintenance—alerting technicians to component degradation before failure.

For field teams, it’s the ultimate reliability tool for power electronics systems. At a Midwestern power plant, retrofitting legacy excitation controllers with PPD113B03R2060 reduced voltage regulation errors by 90% and eliminated 100% of excitation-related shutdowns over a 2-year period. In a Louisiana refinery, its redundant design prevented a complete shutdown when a primary communication port failed—switching to backup in <50ms without process interruption.

Unlike off-the-shelf controllers, it’s purpose-built for power electronics—supporting ABB Powerlink (real-time industrial Ethernet) for direct IGBT converter control and IEC 61850 for grid compliance. It’s the unsung hero of power generation and heavy industry—delivering the speed, precision, and reliability needed to keep critical processes running in the world’s most demanding industrial environments.