Description

Parameter table

| Parameter name | Parameter value |

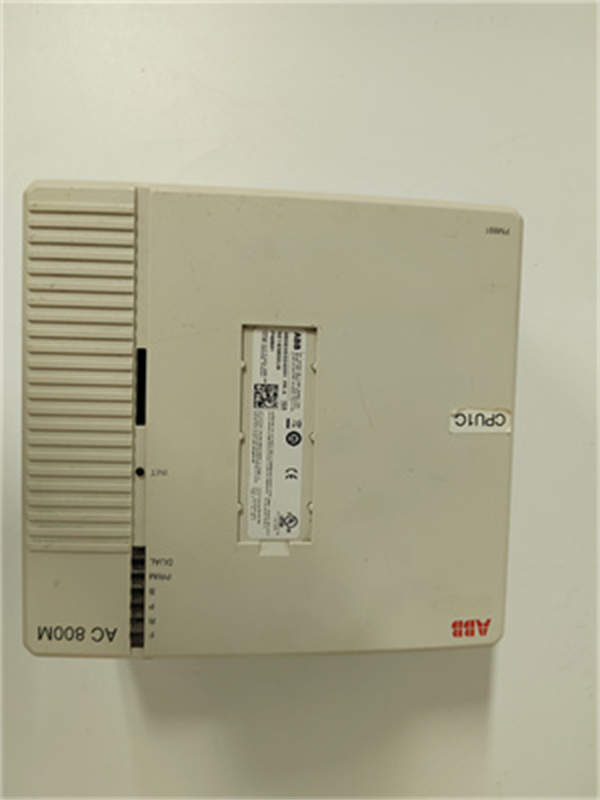

| Product model | PM891 |

| Manufacturer | ABB |

| Product category | High – performance industrial automation controller |

| Dimensions (approx.) (WxHxD in mm) | Compact design for easy integration, specific dimensions available in detailed product documentation |

| Weight | Lightweight for its functionality, weight details in product manuals |

| Processor | High – performance processor for handling complex control algorithms |

| Memory | Sufficient RAM memory for data storage and processing, expandable memory capacity |

| Real – time clock | Equipped with a real – time clock for time – sensitive operations |

| Indicators | LED indicators for status monitoring |

| Push button | Init push button for specific operations |

| Secure digital interface | Present for data storage and transfer |

| Ethernet ports | Two RJ45 ethernet ports (CN1, CN2) for control network connection |

| Serial port | One RJ45 serial port (COM4), isolated and used for configuration tool |

| Redundancy support | Supports CPU redundancy for higher availability (CPU, CEX – bus, communication interfaces and S800 I/O) |

| Communication expansion bus | CEX – bus mounted on the unit for extending on – board communication ports |

| Optical module bus | Can be used to connect seven clusters of S800 I/O units (each up to 12 units) |

| Ethernet address | Each unit has a unique ethernet address for hardware identity |

Product introduction

The ABB PM891 is a high – performance, compact, and modular controller engineered to meet the demanding requirements of industrial automation and control systems. As part of ABB’s comprehensive portfolio of industrial solutions, the PM891 stands out for its ability to handle complex control tasks with precision and reliability.

This monolithic unit comes equipped with a power supply, CPU – boards, and unit termination. Inside, it houses a microprocessor, RAM memory, a real – time clock, LED indicators, an init push button, and a secure digital interface. The lack of an internal battery makes it suitable for applications where long – term battery maintenance is not feasible or desired.

The PM891 serves as the brain of an industrial control setup, receiving input signals from various sensors and devices, processing them according to pre – programmed control logic, and then sending out output signals to control actuators, motors, and other equipment. Its role is crucial in ensuring the smooth operation of industrial processes, from simple manufacturing lines to complex industrial plants.

Core advantages and technical highlights

Powerful processing capabilities: At the heart of the PM891 is a high – performance processor. This enables it to efficiently handle complex control algorithms and large amounts of data input and output. Whether it’s processing real – time sensor data, executing control policies, or performing data analysis, the PM891 can handle these tasks with speed and accuracy. For example, in a high – speed manufacturing process where precise control of machinery is required, the PM891 can quickly process the sensor feedback and adjust the equipment settings to maintain product quality.

Multi – tasking functionality: The controller is designed to be multi – tasking, allowing it to handle multiple control tasks simultaneously. It can monitor sensor data from different parts of a production line, execute control policies based on that data, and respond to user input, all at the same time. This significantly improves the efficiency and response speed of the control system. In a large – scale industrial plant with numerous interconnected processes, the PM891 can manage all these tasks without performance degradation.

Versatile communication interfaces: With two RJ45 ethernet ports (CN1, CN2) for connection to the control network and one isolated RJ45 serial port (COM4) for configuration tools, the PM891 offers great flexibility in communication. It can easily integrate with other controllers, devices, and monitoring systems. Additionally, the communication expansion bus (CEX – bus) on the unit allows for further extension of on – board communication ports using communication interface units. This makes it possible to connect with a wide variety of devices, regardless of their communication protocols, and enables seamless data transmission, remote monitoring, and system integration.

CPU redundancy support: For applications where high availability is crucial, the PM891 supports CPU redundancy. In the event of a failure in one CPU, the other can immediately take over the work, ensuring that the industrial process continues without interruption. This feature is especially important in industries such as power generation, where any downtime can lead to significant losses. By providing this redundancy, the PM891 enhances the overall reliability of the control system.

Scalability: The PM891 is highly scalable. Its expandable memory capacity allows for storing more data and running more complex programs as the industrial application grows. The optical module bus can be used to connect seven clusters of S800 I/O units, with each cluster having up to 12 units. This scalability means that the PM891 can start as a small – scale control solution and be gradually expanded to meet the increasing demands of a growing industrial operation.

Typical application scenarios

Power distribution systems: In power plants and substations, the PM891 can be used to monitor and control the distribution of electrical power. It can receive data from sensors that measure voltage, current, and power quality. Based on this data, it can control circuit breakers, switches, and other electrical equipment to ensure stable power supply. For example, in the event of a sudden power surge or a fault in the grid, the PM891 can quickly detect the issue and take appropriate actions to protect the electrical infrastructure and prevent blackouts.

Manufacturing process control: In manufacturing plants, the PM891 plays a vital role in controlling production lines. It can control the speed of conveyor belts, the operation of robotic arms, and the processing parameters of manufacturing equipment. In an automotive assembly line, the PM891 can ensure that each component is assembled in the correct order and with the right specifications by controlling the movement of robots and the activation of various tools. This helps to improve production efficiency and product quality.

Building automation: In large commercial buildings, the PM891 can be used to automate and control various systems such as lighting, HVAC (heating, ventilation, and air – conditioning), and security systems. It can be programmed to adjust the lighting levels based on the time of day or the amount of natural light available. In the case of HVAC systems, it can control the temperature, humidity, and air circulation to provide a comfortable environment for building occupants while optimizing energy consumption.

Process control in industries: In industries such as chemical, pharmaceutical, and food and beverage, precise process control is essential. The PM891 can control the flow of raw materials, the temperature and pressure in reaction vessels, and the speed of production processes. In a chemical plant, it can ensure that chemical reactions occur at the right conditions, minimizing waste and ensuring product consistency.

ABB PM891

Comparison with related models in the series

Compared with ABB’s higher – end controllers: While ABB offers more advanced and feature – rich controllers for extremely large – scale and complex industrial applications, the PM891 provides an excellent balance between performance and cost for mid – range applications. Higher – end models may offer more processing power, larger memory capacities, and additional communication interfaces. However, the PM891 is more cost – effective for small – to – medium – sized industrial setups where the additional features of the higher – end models may not be fully utilized. For example, a small – scale manufacturing factory may find the PM891 sufficient for its production line control needs, while a large multinational chemical plant may require a more advanced controller.

Compared with other brands’ similar controllers: ABB’s reputation for quality and reliability gives the PM891 an edge. ABB has a long – standing history of research and development in industrial automation, resulting in products that are well – engineered and built to last. The PM891 benefits from ABB’s global network of technical support, which can provide prompt assistance in case of any issues. Additionally, the PM891 may offer better integration with other ABB products in an industrial ecosystem, such as ABB’s drives, motors, and power distribution equipment. Competing products may not be able to match this level of seamless integration and comprehensive support.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the PM891, carefully select an appropriate installation location. The area should be clean, dry, and free from excessive vibrations and electromagnetic interference. Check the power supply to ensure it meets the requirements of the PM891. Gather all the necessary installation tools, such as screwdrivers, wire strippers, and crimping tools. Review the system architecture to ensure compatibility with existing devices, especially when integrating the PM891 into an existing industrial control system. Make sure to follow all safety procedures, including proper grounding and isolation of the power supply.

Commissioning process: Once installed, connect the PM891 to the relevant power sources, control network, and other devices according to the provided wiring diagrams. Double – check all connections to ensure they are secure and properly insulated. Power on the device and perform an initial self – test. Use the device’s built – in configuration tools or the connected configuration software (via the COM4 port) to set up the control parameters, communication settings, and other necessary configurations according to the specific requirements of the application. Test the functionality of the PM891 by simulating various input signals and verifying the corresponding output responses. Monitor the performance using appropriate testing equipment to ensure that the controller is operating as expected.

Maintenance suggestions: Regularly inspect the PM891 for any signs of physical damage, such as cracks in the housing or loose connections. Clean the device periodically to remove dust and debris, as these can affect the performance of internal components. Check the communication status with other devices in the network at regular intervals to ensure seamless data transfer. Review the controller’s logs (if available) to look for any patterns or signs of abnormal behavior. If any issues are detected, refer to the troubleshooting section of the product manual. In case of more complex problems, contact ABB’s technical support team, who can provide remote or on – site assistance. If the application requires an upgrade in functionality, consider updating the controller’s firmware to the latest version, following the official ABB guidelines.

Service and guarantee commitment

ABB offers a standard [warranty period] warranty for the PM891, covering any manufacturing defects. ABB’s global technical support team is available around the clock. They can provide remote support through online communication channels, guiding customers through installation, commissioning, and troubleshooting processes. In cases where on – site assistance is required, trained technicians can be dispatched to the customer’s location. ABB also regularly updates the product’s software and technical documentation to improve performance, add new features, and address any potential security vulnerabilities. This commitment to service and support ensures that customers can rely on the PM891 for long – term, reliable operation in their industrial automation and control systems.