Description

Key Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | PM820-1(3BSE018107R1) |

| Manufacturer | ABB Process Automation (AC800M Product Line) |

| CPU | 32-bit RISC (100+ MIPS) for real-time control |

| Memory | 16MB RAM (ECC), 8MB Flash (program storage) |

| Communication | Ethernet (TCP/IP), PROFIBUS DP, S800 I/O backplane |

| Power Supply | 24VDC ±10% (5W typical, 8W max) |

| Isolation | 2500VAC (channel-to-backplane, power-to-logic) |

| Operating Temp | -20°C to +60°C (derate >55°C) |

| Mounting | DIN rail (S800 I/O rack), hot-swappable with proper procedure |

| Diagnostics | LED status (power/comm/run/fault), module health, ECC error detection |

| Protection | IP20 (module), IP65 (with sealed terminal) |

| Weight | 0.6kg |

| Dimensions | 178mm × 104mm × 35mm |

| Hot-Swap | Yes (with S800 I/O rack & shutdown protocol) |

| Certifications | CE, UL, ATEX, IEC 61131-3 compliant |

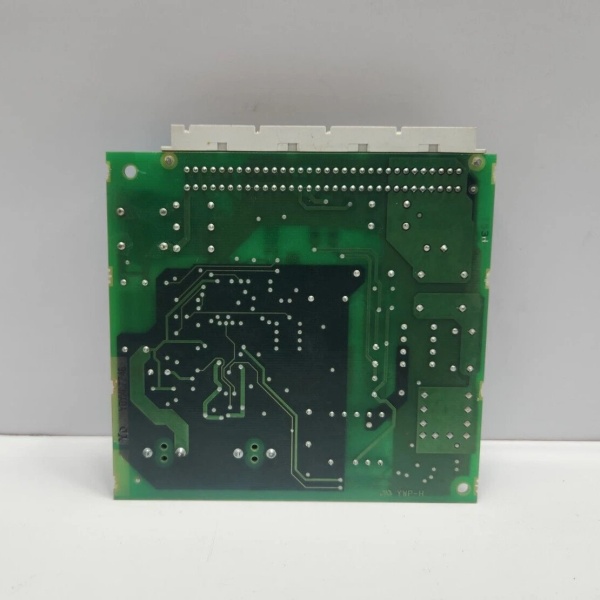

ABB PM820-1

Field Application & Problem Solved

In mid-scale distributed control with AC800M, the PM820-1 solves the conflict between processing capacity and system simplicity. A refinery’s crude distillation unit faced main controller overload from complex interlocks, requiring costly upgrades and causing delays during logic changes. This module offloads control loops, improves response time by 12–15%, and reduces network traffic by 20–25%.

Typical deployments:

- Power Plant Auxiliaries: Boiler feedwater, fan control, cooling systems with custom interlocks

- Refinery Process Units: Safety shutdown, valve control, alarm monitoring for distillation columns

- Chemical Batch Processing: Recipe execution, batch tracking, quality control with real-time logic

- Manufacturing Lines: Robotic coordination, conveyor sync, packaging with precise timing

Installation & Maintenance Pitfalls (Expert Tips)

- Rack Compatibility: Only hot-swappable in S800 I/O racks with redundant power. A power plant tech used a non-redundant rack, causing module damage and comm failures—always confirm rack model before installation.

- Hot-Swap Protocol: Never pull live without proper shutdown. A refinery incident: tech pulled mid-upset, causing reactor trip and $100k loss. Steps: Disable in Control Builder M → Wait for “safe to remove” LED → Verify bus stability via diagnostics before extraction.

- Grounding & Shielding: Improper grounding introduces EMI, leading to false signals. Mount on grounded steel chassis, use 35mm² copper for safety ground, keep signal/power cables ≥30cm apart. A paper mill re-routed cables to eliminate 0.7% false triggers in safety interlocks.

- Firmware Match: Mismatched firmware between CPU and controller causes timeouts/resets. Use ABB DTM to update to v4.5.0+ for full redundancy/hot-swap support.

- Memory Allocation: Overloading RAM with unoptimized logic crashes the module. Allocate 50% RAM for control loops, 30% for data, 20% for diagnostics. A food plant avoided overflow by reallocating memory for high-speed inputs.

ABB PM820-1

Technical Deep Dive & Overview

The PM820-1 is a 32-bit RISC CPU module for AC800M controllers, serving as the core for logic execution, data processing, and communication in 800xA DCS. It uses a 100+ MIPS processor to handle multiple control loops, interlocks, and sequence logic without overloading the main controller.

Internally, 16MB ECC RAM ensures data integrity in harsh environments, while 8MB Flash stores programs through power cycles. Communication via Ethernet (TCP/IP) and PROFIBUS DP (12Mbps) supports cyclic/acyclic data transfer, with seamless integration into S800 I/O backplane.

Industrial design includes conformal coating for humidity/chemical resistance, -20°C to +60°C operation, and 3g vibration tolerance—built for power plants, refineries, and manufacturing floors. Unlike generic CPUs, it natively supports ABB’s Function Blocks, Structured Text, and Ladder Logic, ensuring zero configuration conflicts in 800xA systems.

This is the go-to module for mid-range AC800M systems needing distributed intelligence, reducing main controller load and improving responsiveness. It excels in safety-critical apps like ESD, fire/gas detection, and turbine protection where fast, reliable processing is non-negotiable.