Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PM802F |

| Manufacturer | ABB |

| Product Category | High-availability Controller |

| Processor | Dual-core ARM Cortex-A9 @ 800 MHz |

| Memory | 512 MB RAM / 4 GB Flash |

| Redundancy Support | CPU pair (1+1 hot standby) |

| I/O Capacity | Up to 1,000 signals per controller |

| Communication Ports | 4x Ethernet (2x redundant), 2x RS485 |

| Protocols | Modbus TCP, OPC UA, IEC 61850, PROFINET |

| Safety Certification | SIL 3 (IEC 61508), Cat 4/PLe (ISO 13849) |

| Operating Temperature | -40°C to +70°C |

| Power Supply | 24 VDC (18–30 V) with surge protection |

| MTBF | >350,000 hours (TÜV certified) |

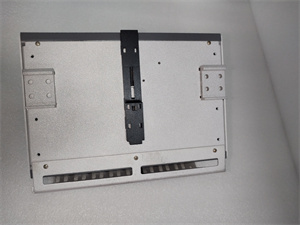

ABB PM802F

Product Introduction

The ABB PM802F is a fault-tolerant controller engineered for mission-critical automation within ABB’s AC 800M high-integrity control system. Designed for power generation, oil & gas, and water treatment applications, this ruggedized processor executes complex control strategies with deterministic sub-millisecond cycle times. The ABB PM802F features dual-redundant architecture with automatic switchover (<50 ms) during failures, ensuring zero process interruption.

Integrated with ABB’s 800xA DCS ecosystem, the PM802F supports advanced cybersecurity protocols including role-based access control and encrypted communications. Its modular design allows seamless expansion via S800 I/O modules, while native IEC 61131-3 programming enables multi-language control logic development. For industries demanding maximum uptime, the ABB PM802F delivers military-grade resilience against electromagnetic interference, vibration, and extreme temperatures.

Core Advantages and Technical Highlights

Ultimate reliability: Dual-core processors with separate watchdog circuits maintain SIL 3 safety integrity. The “Compare-and-Execute” mechanism synchronizes redundant CPUs at every scan cycle. Hot-swappable components enable maintenance without shutdown.

Performance leadership: Processes 10,000 Boolean operations/ms with 0.5 ms deterministic I/O response. Integrated hardware accelerators handle motion control and PID loops independently, freeing CPU resources.

Cyber-secure architecture: Hardware-trusted platform module (TPM) stores encryption keys, while whitelisting technology blocks unauthorized code execution. Meets IEC 62443-3-3 SL2 requirements.

Engineering efficiency: Auto-discovery of S800 I/O modules reduces configuration time by 70%. Supports online modification of control logic during operation.

Typical Application Scenarios

In combined-cycle power plants, redundant ABB PM802F pairs control turbine sequencing and balance-of-plant systems, synchronizing switchovers during grid frequency fluctuations. Their SIL 3 certification enables deployment in burner management systems (BMS), where <50 ms failover prevents boiler trips.

For offshore platforms, the controller’s -40°C cold-start capability ensures reliable operation of emergency shutdown (ESD) valves in Arctic conditions. Corrosion-resistant coatings withstand salt fog exposure while redundant Ethernet rings maintain communication during cable damage.

Water treatment facilities leverage the PM802F for membrane bioreactor (MBR) control, where its millisecond-precision PID loops optimize chemical dosing. Integrated IEC 61850 support simplifies substation integration for pump motor control centers.

ABB PM802F

Related Model Recommendations

PM803F: Enhanced version with 1 GHz processor & 8 GB flash

CI854: PROFIBUS DP communication interface module

SD821: 16GB industrial SD card for program storage

S800 I/O Modules: e.g., AI825 (analog input), DI810 (digital input)

TP830: Touch panel HMI for local operation

SA801F: Safety controller for SIL 3 interlock systems

CP405: Control panel for rack mounting

DSQC377B: Redundant power supply unit

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount redundant PM802F controllers in separate 19″ racks with ≥200mm vertical clearance. Use ABB-approved 24VDC power feeds with 20A circuit breakers. Ground chassis via 10mm² copper cable to central busbar (impedance <0.1Ω).

Maintenance suggestions: Monitor “CPU Sync Deviation” via Control Builder M software; values >10µs indicate need for fiber optic sync cable inspection. Replace cooling fans every 5 years. Perform annual memory battery check (min. 2.8V). Always update both CPUs simultaneously during firmware upgrades.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the PM802F, covering 24/7 technical support with 4-hour critical response commitment. Extended lifecycle support guarantees spare parts availability for 15 years after discontinuation. All units undergo 168-hour burn-in testing with thermal cycling (-40°C to +85°C) and 100% redundancy switchover validation. Cybersecurity firmware updates are provided free for 5 years. SIL certification includes TÜV Rheinland validation reports.