Description

Key Technical Specifications

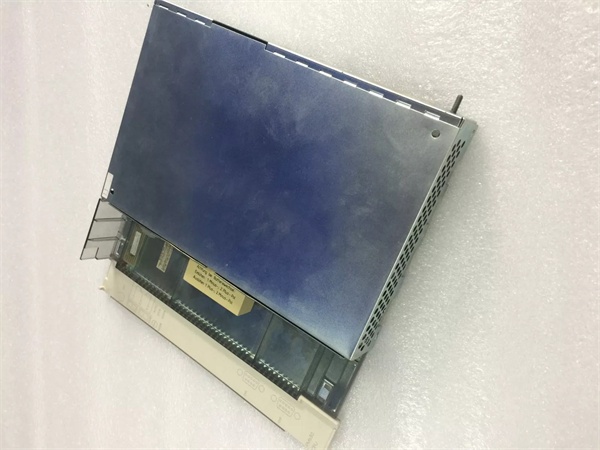

- Model Number: ABB PM630 3BSE000434R1

- Manufacturer: ABB Industrial Automation Division

- CPU Type: 32-bit ARM Cortex-M3 processor, 80MHz clock speed

- Memory: 64KB battery-backed RAM (volatile), 256KB non-volatile flash memory

- Programming Compliance: IEC 61131-3 (Ladder Logic, Function Block Diagram, Structured Text, etc.)

- Communication Ports: 1 × Ethernet (10/100Mbps), 1 × RS485 (Modbus RTU master/slave)

- Power Supply: 24VDC ±10%, 0.2A typical current draw (no load), 0.4A max

- Operating Temperature: -25°C to +60°C (-13°F to +140°F)

- Isolation Rating: 500V AC (I/O to power); 250V AC (communication ports)

- Compatibility: ABB AC500 I/O modules (AI810, AO810, DI810), AC500-eCo expansion adapters

- Mechanical Design: DIN rail mount (35mm), 70mm × 125mm × 100mm dimensions, modular rack-compatible

- Certifications: CE, UL 508, RoHS 2.0, IEC 61131-3, IEC 61010-1

ABB PM630 3BSE000434R1

Field Application & Problem Solved

Medium-scale automation projects—process skids, packaging lines, and material handling systems—often struggle with two critical pain points: unreliable budget PLCs and bulky hardware that wastes cabinet space. A Michigan water treatment plant lost $9,000/year in downtime due to a generic PLC that crashed weekly during chemical dosing cycles, requiring manual resets. Another issue: legacy CPUs need separate communication modules for Ethernet, cluttering cabinets and increasing wiring complexity. A Pennsylvania packaging plant’s control cabinet had 8 extra wires for a standalone Ethernet module, leading to monthly connectivity failures and 3-hour troubleshooting sessions.

You’ll find the PM630 in compact automation cells, remote process skids, and food processing lines—anywhere space is limited but reliability and connectivity can’t be compromised. It acts as the “brain” for medium-scale control loops, executing logic and communicating with HMIs, VFDs, and upper-level DCS systems via built-in Ethernet/RS485. Its core value is compact reliability plus integrated connectivity. The built-in Ethernet eliminated the Pennsylvania plant’s extra wiring, cutting communication failures to zero. ABB’s industrial-grade design (unlike budget PLCs) handles temperature swings and electrical noise, with the Michigan plant seeing zero crashes in 24 months after replacement.

Installation & Maintenance Pitfalls (Expert Tips)

- Reverse Polarity Destroys the CPU: Rookies mix up 24VDC positive/negative wires, frying the power supply. A Ohio food processor did this, costing $450 in replacement and 4 hours of downtime. Use color-coded wiring (red = +24VDC, black = 0V) and verify with a multimeter before power-up— the PM630 has no reverse polarity protection.

- Don’t Overload the Ethernet Port: The built-in Ethernet port supports up to 8 concurrent TCP/IP connections—exceeding this causes communication drops. A Wisconsin brewery connected 12 HMIs to one PM630, leading to intermittent data loss. Use a small Ethernet switch (ABB recommends 1SFL500002R0001) for more than 8 devices, and prioritize critical traffic (e.g., DCS communication) via QoS settings.

- Firmware Mismatch Breaks I/O Communication: Outdated firmware causes compatibility issues with newer AC500 I/O modules. A North Carolina chemical plant ran a PM630 with v2.0 firmware alongside a DI810 v3.0 module—inputs failed to register. Update firmware via the Ethernet port using ABB’s Automation Builder software; always match CPU firmware to I/O module versions (within ±1 release).

- Poor Grounding Causes Signal Chatter: Daisy-chaining the PM630’s ground to I/O modules introduces noise in analog signals. A Illinois material handling system’s pressure sensor readings fluctuated by 10% until we grounded the CPU’s chassis directly to the cabinet ground bar (use 4mm² copper wire). Never share ground paths between the CPU and power modules—this couples EMI into control logic.

ABB PM630 3BSE000434R1

Technical Deep Dive & Overview

The PM630 3BSE000434R1 is a compact, high-reliability CPU module for ABB’s AC500 series, engineered to balance performance and space efficiency for medium-scale automation. At its core, a 32-bit ARM Cortex-M3 processor executes control logic at 1ms per 1,000 function blocks—fast enough for most process skid and packaging line applications. The 64KB battery-backed RAM preserves process data during power outages, while 256KB flash stores firmware and application code.

What sets it apart from budget alternatives is integrated connectivity and industrial ruggedness. The built-in Ethernet port supports Modbus TCP and ABB’s native communication protocol, eliminating the need for standalone modules and reducing failure points. The RS485 port handles Modbus RTU for legacy devices like pressure transmitters and VFDs. The module’s conformal-coated PCB resists dust and moisture, while the -25°C to +60°C operating range works in unconditioned cabinets—critical for outdoor process skids.

The PM630’s modular design allows scaling with AC500 I/O modules, making it future-proof for growing applications. Its compact DIN rail footprint saves 40% cabinet space compared to full-size CPUs, ideal for tight skid-mounted control systems. For plants where downtime costs $8k+/hour, this module isn’t just a compact CPU—it’s a reliable workhorse that delivers performance without sacrificing space or durability.