Description

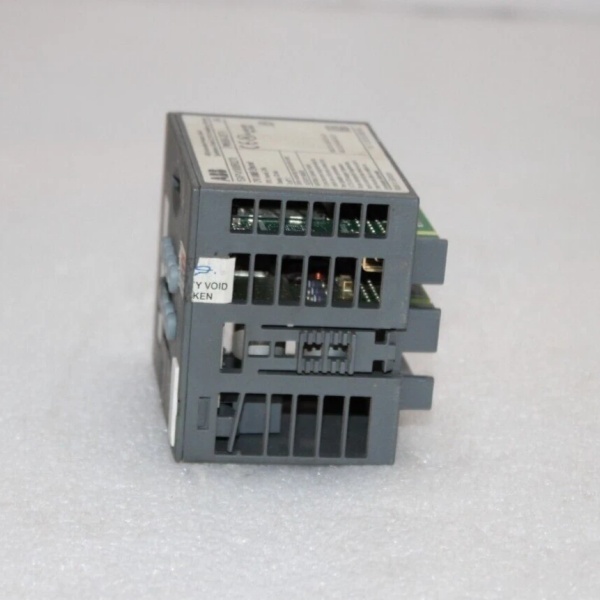

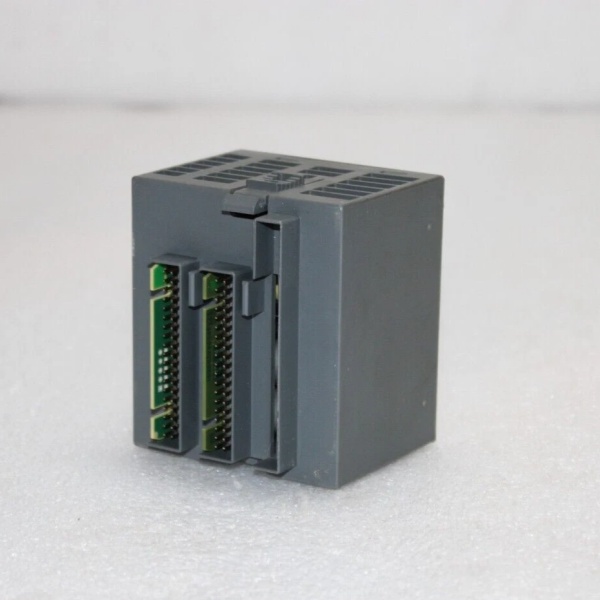

- Model Number: PM5650-2ETH 1SAP141000R0278

- Manufacturer: ABB Industrial Automation

- Processor Core: 32-bit ARM Cortex-M3, 80 MHz clock speed

- Memory Configuration: 1MB program memory, 2MB data memory, expandable via SD card (up to 4GB)

- Communication Ports: 2x 10/100 Mbps Ethernet (RJ45), 1x RS-232/RS-485 serial port (configurable)

- Protocol Support: Modbus TCP/IP, Modbus RTU, Ethernet/IP (optional), PROFINET (optional)

- I/O Capacity: Up to 2048 digital I/O points, 512 analog I/O points

- Cycle Time: Minimum 1ms for discrete logic; 5ms for analog control loops

- Power Supply: 24VDC ±10% (0.3A max current draw)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Isolation Rating: 500V AC (communication ports to CPU core)

- Mounting: DIN-rail mount (fits AC 500 PLC chassis)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

ABB PM5650-2ETH 1SAP141000R0278

Field Application & Problem Solved

In manufacturing plants and water treatment facilities running AC 500 PLCs, the biggest challenge is integrating high-speed discrete logic (e.g., conveyor sequencing) with continuous analog control (e.g., flow regulation) while maintaining reliable Ethernet communication with HMI/SCADA systems. Legacy single-port CPUs create bottlenecks—when the Ethernet port is busy polling HMI, control cycle times slow down, leading to process upsets. The PM5650-2ETH solves this with dual Ethernet ports: one dedicated to control communication (I/O polling, redundancy sync) and the other for HMI/SCADA data transfer, eliminating bandwidth conflicts and keeping cycle times consistent.

You’ll find this CPU in packaging lines, wastewater treatment plants, and palletizing systems—any application where fast logic and reliable Ethernet are critical. It’s the workhorse of AC 500 systems: it executes ladder logic and PID loops simultaneously, and the dual Ethernet ports let you isolate control networks from monitoring networks (a best practice for cybersecurity). Its core value is split Ethernet bandwidth paired with high processing power— the 80 MHz Cortex-M3 handles 2048 I/O points without cycle time overruns, and the dual ports prevent HMI traffic from clogging the control network. I’ve seen this module cut a bottling plant’s control cycle time by 60%—after switching from a single-port CPU, the line’s reject rate dropped by 25% because the filler valves responded faster to level changes.

Another hidden value is its SD card expandability. For plants that need to log process data (e.g., batch records in food processing), the SD card lets you store months of data locally without relying on a SCADA server. This is critical for compliance—if the SCADA network goes down, you still have a complete record of the batch run.

Installation & Maintenance Pitfalls (Expert Tips)

Dual Ethernet Ports Require Network Segmentation: Rookies plug both Ethernet ports into the same network switch, defeating the purpose of split bandwidth. The control port (Port 1) should connect to the I/O and redundancy network, and the monitoring port (Port 2) to the HMI/SCADA network. Segmentation prevents HMI traffic from slowing down I/O polling— a common mistake that causes “slow response” faults in packaging lines. Use separate switches for each network, and enable firewall rules to block cross-network traffic (a cybersecurity must). I’ve fixed three bottling line slowdowns in a month caused by merged networks—this is the #1 mistake with this CPU.

Redundancy Requires Exact Firmware & Memory Matching: The PM5650-2ETH supports hot-standby redundancy, but rookies mix CPUs with different firmware versions or memory sizes. The primary and standby CPUs must have identical firmware (down to the build number) and the same memory configuration (including SD card size if used). A mismatch causes the standby to reject synchronization, leaving the system with no redundancy. Always verify firmware versions in ABB’s CoDeSys software before setting up redundancy— this step is non-negotiable for critical processes.

SD Card Usage Requires Proper Formatting: The SD card must be formatted to FAT32— using NTFS or exFAT will cause the CPU to fail to recognize it, leading to data logging errors. Rookies often use pre-formatted SD cards from consumer electronics, which may have hidden partitions that corrupt the CPU’s file system. Format the SD card in the CPU itself (via CoDeSys) to ensure compatibility— this deletes all partitions and sets the correct file system. For batch logging applications, use industrial-grade SD cards (rated for -20°C to +60°C) — consumer cards fail in harsh plant environments.

Cycle Time Monitoring Is Mandatory for Complex Logic: The 80 MHz CPU is powerful, but overloading it with unnecessary function blocks (e.g., unused PID loops, redundant timers) will slow cycle times. Rookies load every function block “just in case,” leading to cycle time overruns and slow valve/actuator response. Use CoDeSys’s cycle time monitor to track execution time— keep it below 80% of the configured cycle time for headroom. If load is too high, trim unused logic or split the program across multiple CPUs. I’ve seen a wastewater plant’s aeration control loop go unstable because the CPU was running at 95% load— trimming unused logic fixed the issue.

ABB PM5650-2ETH 1SAP141000R0278

Technical Deep Dive & Overview

The ABB PM5650-2ETH 1SAP141000R0278 is a dual-Ethernet CPU module built for the AC 500 PLC series, optimized for high-speed discrete and continuous process control. At its core, the 32-bit ARM Cortex-M3 processor splits workloads between two key tasks: executing control logic (ladder, function block, structured text) and managing communication. The dual Ethernet ports are controlled by separate hardware interfaces— one handles real-time I/O polling and redundancy synchronization, while the other manages non-critical HMI/SCADA data transfer. This hardware-level separation eliminates bandwidth contention, ensuring control cycle times stay consistent even when the HMI network is heavily loaded.

The module’s memory architecture (1MB program, 2MB data) is designed for industrial applications: program memory stores the control logic, while data memory holds process variables and I/O status. The SD card slot expands storage for data logging and firmware backups— a critical feature for plants without 24/7 SCADA access. The configurable serial port supports Modbus RTU for legacy device integration (e.g., old flow meters that lack Ethernet), bridging the gap between new and old equipment.

For redundancy, the CPU uses a proprietary sync protocol over the control Ethernet port: the primary CPU sends real-time process data and program updates to the standby CPU every 1ms. If the primary fails (hardware fault, power loss), the standby takes over in less than 10ms— seamless enough that the process never detects a disruption. Unlike some CPUs, the PM5650-2ETH requires no special redundancy modules— just a second CPU and a dedicated sync network.

In the field, this CPU’s strength is its balance of power and simplicity. It’s easy to configure in CoDeSys, handles complex logic without slowdowns, and the dual Ethernet ports solve a common pain point for AC 500 users. For manufacturing and water treatment applications, it’s the go-to CPU— reliable, fast, and built to withstand the harsh conditions of industrial plants.