Description

Key Technical Specifications

- Model Number: PFBI 161

- Manufacturer: ABB Process Automation Division

- Digital Input Channels: 16 independent, galvanically isolated channels

- Input Signal Type: 24VDC (configurable per channel: PNP sourcing / NPN sinking)

- Input Current: 3mA (PNP), 5mA (NPN) typical

- Isolation Rating: 2500VAC (channel-to-channel, channel-to-backplane, channel-to-power)

- Power Supply: 24VDC ±10% (0.8W typical, 1.2W max current draw)

- Operating Temperature: -20°C to +60°C (ambient, derate above 55°C)

- Mounting Type: S800 I/O MTU (Module Termination Unit), 35mm DIN rail compatible

- Diagnostic Features: Channel-level short-circuit detection, open-wire monitoring, module health status, backplane communication fault alerts

- Protection Class: IP20 (module), IP65 (with sealed MTU)

- Weight: 0.4kg

- Compatible Controllers: ABB AC 800M, Advant OCS, Symphony Plus DCS

- Response Time: ≤1ms (signal detection)

ABB PFBI 161

Field Application & Problem Solved

In process industries—refineries, power plants, chemical facilities—the biggest challenge with digital inputs is reliable status sensing of field devices (limit switches, proximity sensors, safety interlocks) amid electrical noise and harsh conditions. Legacy digital input modules lack galvanic isolation and diagnostics, leading to false alarms, missed fault detections, and costly downtime. At a Gulf Coast refinery, non-isolated modules caused 4 unplanned pump shutdowns in 6 months due to ground loop interference, costing $300k in lost production.

This module solves those reliability gaps. You’ll find it monitoring pump run/stop status in refinery distillation units, valve position switches in power plant boiler systems, and safety gate interlocks in chemical batch processing. It’s the workhorse for S800-based DCS systems where high channel density and noise immunity are critical—its 16 isolated channels replace 2 8-channel legacy modules, saving cabinet space and reducing wiring complexity. In a Midwest coal-fired power plant, retrofitting with PFBI 161 eliminated 90% of false input alarms and cut troubleshooting time for sensor issues from hours to minutes.

Its core value is rugged isolation and actionable diagnostics. Unlike generic modules, its 2500VAC galvanic isolation breaks ground loops and blocks EMI from motors, VFDs, and high-voltage equipment—common in industrial settings. The channel-level diagnostics pinpoint issues (e.g., shorted proximity sensor on channel 12) directly, eliminating guesswork. For field teams, this means fewer unnecessary field visits, faster fault resolution, and confidence that equipment status data is accurate—critical for safe, efficient process operation.

Installation & Maintenance Pitfalls (Expert Tips)

- PNP/NPN Configuration Must Match Sensors: Rookies often install the module without configuring input types, leading to non-responsive channels. I saw this at a paper mill where PNP proximity sensors were wired to NPN-configured channels—resulting in 2 hours of missed web break detections. Use ABB Control Builder to set each channel’s input type, and verify with a multimeter: PNP channels should read 24VDC when active; NPN channels should read 0VDC.

- Grounding Separates Noise from Signals: Improper shield grounding introduces EMI, causing erratic input signals. Run sensor cable shields to a single point at the MTU (not at the sensor), and connect to the MTU’s dedicated ground terminal. At a Texas refinery, re-routing 16 sensor cables away from 480V motor lines eliminated false pump status alarms caused by electromagnetic interference.

- Don’t Overload Input Channels: Each channel is rated for max 10mA—connecting high-current devices (e.g., 24VDC relays) burns out the module’s opto-isolators. A technician at a chemical plant made this mistake, ruining 3 channels in one day. Use signal converters for high-current devices, or stick to low-power sensors (proximity switches, limit switches) that draw ≤5mA.

- Follow Hot-Swap Protocol to Avoid Bus Crashes: The module is hot-swappable, but pulling it mid-backplane scan corrupts the S800 I/O bus. At a power plant, a rushed swap during a process upset crashed the entire I/O rack, tripping a turbine. Always disable the module in Control Builder, wait for the “safe to remove” indicator, and confirm bus stability before pulling the module.

- Tighten Terminal Screws to Spec: Loose terminals in vibrating environments (e.g., pump skids) cause intermittent connections. Use a torque wrench to tighten MTU terminal screws to 0.8-1.0 Nm (7-9 lb-in) per ABB specs. In a Pennsylvania chemical plant, this simple step reduced intermittent input faults by 85% on a batch reactor’s safety interlocks.

ABB PFBI 161

Technical Deep Dive & Overview

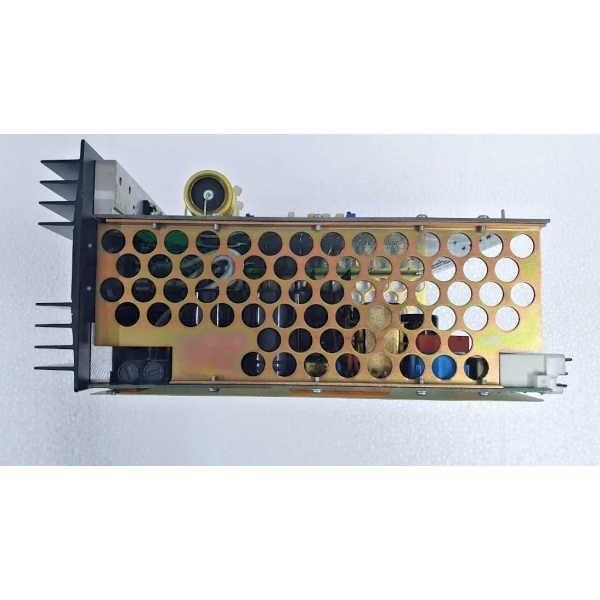

The PFBI 161 is a 16-channel digital input module designed for ABB’s S800 I/O system, the backbone of AC 800M and Advant OCS control architectures. It acts as the interface between discrete field sensors and the DCS, converting on/off status signals into digital data while providing robust noise immunity and diagnostics.

Internally, each channel uses an opto-isolator to separate field wiring from the module’s electronics—critical for blocking ground loops and EMI that plague non-isolated modules. The opto-isolators are rated for 2500VAC, ensuring protection even in high-voltage industrial environments. A dedicated microcontroller manages channel status, diagnostics, and communication with the S800 backplane, operating at a response time of ≤1ms to capture fast-changing sensor signals.

The module stores configuration (PNP/NPN, input filters) in non-volatile EEPROM, so settings survive power cycles and module replacement. The diagnostics engine monitors each channel for short circuits, open wires, and overcurrent, while also checking module power and backplane communication. Faults are transmitted to the DCS via the I/O bus, with channel-specific alerts that eliminate manual troubleshooting of 16 separate sensors.

What makes it field-tough is its industrial-grade design: conformal-coated PCB to resist humidity, dust, and chemical vapors; wide operating temperature range (-20°C to +60°C); and vibration tolerance up to 5g. It’s built to withstand the abuse of refinery pump rooms, power plant boiler houses, and chemical processing areas—where lesser modules fail within months. Unlike generic digital input modules, it’s engineered for seamless integration with ABB’s DCS software, with zero configuration conflicts and native support for control logic functions like interlock programming. This is the module you install when you need accurate, reliable status data—day in, day out—without the headache of false alarms or unplanned downtime.