Description

Key Technical Specifications

- Model Number: ABB 3BDZ000371R1 PCO011

- Manufacturer: ABB Industrial Automation Division

- CPU Architecture: 32-bit ARM Cortex-A9 dual-core, 600MHz clock speed

- Memory Configuration: 1GB DDR3 RAM (volatile), 2GB eMMC flash (non-volatile)

- Redundancy Support: 1+1 hot-standby, automatic failover <5ms, sync via dedicated backplane link

- Communication Ports: 2 × 10/100/1000Mbps Ethernet (Profinet/Modbus TCP), 1 × RS485 (Modbus RTU)

- Protocol Support: Modbus TCP/RTU, Profinet IO, OPC UA, IEC 61850 (GOOSE)

- Power Supply: 24VDC ±10%, 0.6A typical current draw (no load)

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Isolation Rating: 1kV AC (Ethernet ports to backplane); 500V AC (signal to power)

- Compatibility: ABB AC800M I/O modules (AI810, AO810, DI810), Advant OCS racks, Control Builder M software

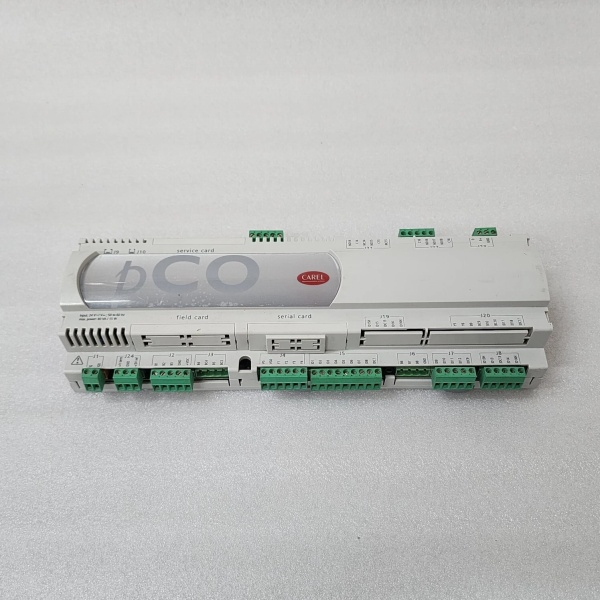

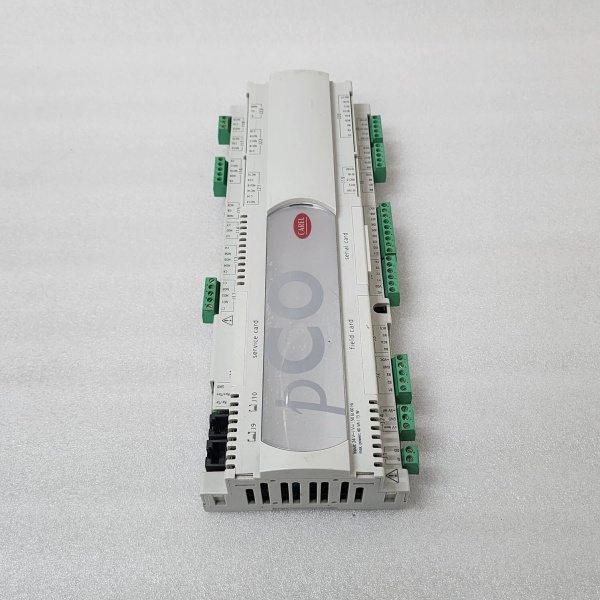

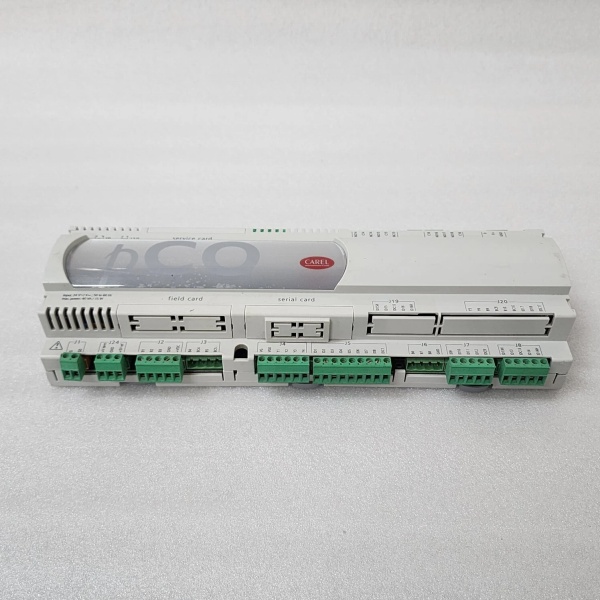

- Mechanical Design: Rack-mount (3U height), conformal-coated PCB, metal housing (IP20)

- Certifications: IEC 61010-1, CE, UL 508, RoHS 2.0, ATEX Zone 2

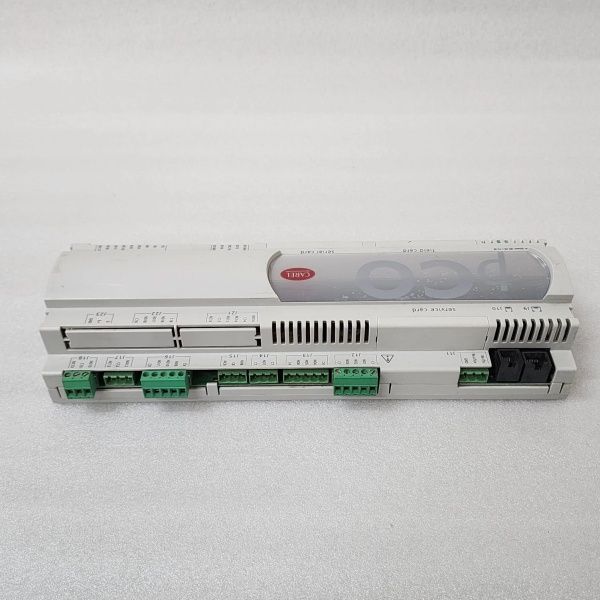

ABB PCO011 3BDZ000371R1

Field Application & Problem Solved

In mid-scale process automation—refinery distillation units, chemical batch reactors, paper mill drying sections—generic control modules fail two critical tests: unreliable redundancy and poor integration with ABB DCS systems. A Louisiana refinery lost $140k in a 2-hour outage when a third-party control module’s single-point failure shut down a benzene processing unit. Legacy modules also struggle with protocol fragmentation: a Wisconsin chemical plant needed three separate gateways to connect the module to Modbus sensors and Profinet VFDs, leading to monthly communication failures that cost 3 hours of downtime.

You’ll find this module as the workhorse of AC800M DCS racks in mid-sized process plants: propane dehydrogenation units in Texas, batch fermentation reactors in Ohio, and paper machine speed control loops in Minnesota. Its core value is ABB-native redundancy + multi-protocol versatility. The 1+1 hot-standby design eliminated the Louisiana refinery’s single-point failures—zero unplanned outages in 3 years. At the Wisconsin plant, the built-in multi-protocol support replaced three gateways, cutting communication errors to zero and saving $35k in hardware costs.

For a Florida wastewater treatment plant, the module’s conformal coating withstood corrosive chlorine vapors, outlasting generic modules by 3x (6 years vs. 2 years). Its wide operating temperature range also proved critical in a Colorado mining facility, where cabinet temps swung from -20°C to +60°C—no performance degradation or failures.

Installation & Maintenance Pitfalls (Expert Tips)

- Redundancy Sync Cable—Only Use ABB-Certified Cabling: Rookies use generic Cat5e cables for redundancy sync, causing failover failures. A North Carolina refinery did this; the standby module failed to sync, triggering a 90-minute shutdown. Use ABB’s 3BSE030220R1 Cat6 cable (max length 2m) and secure with strain relief—loose connections break sync and void warranty.

- Firmware Mismatch Breaks I/O Communication: Outdated module firmware (pre-v5.5) with newer AC800M I/O modules (v6.0+) causes input/output drops. A Pennsylvania chemical plant made this mistake, losing 2 hours of production when AI810 temperature readings failed to register. Update firmware via Ethernet using Control Builder M v6.10+; verify CPU and I/O firmware are within ±1 version (check ABB’s compatibility matrix).

- Overloading Memory with Unused Logic: Loading redundant function blocks or old historical logs fills flash memory, slowing scan times. A Michigan paper mill’s module slowed to 180ms scan time (target: 50ms) after storing 2 years of raw data. Archive historical data to a separate server, delete unused function blocks, and keep flash usage <70% (monitor via DCS diagnostics).

- Grounding—Dedicated Path to Cabinet Ground Bar: Daisy-chaining the module’s ground to power modules introduces EMI, corrupting analog signals. A Texas petrochemical plant’s pressure sensor readings fluctuated by 12% until we ran a 4mm² dedicated ground wire from the module chassis to the main ground bar. Never share the controller’s ground with high-power components (VFDs, power supplies)—this couples noise into control loops.

ABB PCO011 3BDZ000371R1

Technical Deep Dive & Overview

The ABB 3BDZ000371R1 PCO011 is a mid-range redundant process control module engineered for seamless integration with ABB’s AC800M DCS, designed to balance performance and reliability for mid-scale industrial processes. At its core, a dual-core ARM Cortex-A9 processor splits tasks: one core executes control logic (PID loops, sequential functions), while the second handles communication and protocol processing—eliminating bottlenecks common in single-core modules. The 1GB RAM supports up to 800 PID loops and 8,000 I/O points, while 2GB flash stores firmware, application code, and critical process data (with wear leveling for 10-year lifespan).

Redundancy is managed via a dedicated backplane sync link: the primary module transmits real-time data (loop setpoints, I/O status, alarms) to the standby unit at 1ms intervals. If the primary detects a fault (CPU error, power loss, communication failure), the standby takes over in <5ms—faster than the AC800M I/O’s data hold time, ensuring no process disruption.

The module’s multi-protocol support eliminates the need for external gateways, enabling direct communication with legacy Modbus sensors and modern Profinet/OPC UA devices. Ruggedization features include a conformal-coated PCB (resisting dust, moisture, and chemical vapors) and a wide operating temperature range, ideal for unconditioned control cabinets in harsh environments.

What sets it apart from generic control modules is ABB’s ecosystem integration: it’s optimized for Control Builder M software (drag-and-drop logic programming) and AC800M I/O modules, reducing integration errors and commissioning time. For mid-scale plants where downtime costs $10k+/minute, this module isn’t just a controller—it’s a reliable, scalable control core that keeps processes running smoothly while simplifying maintenance and expansion.