Description

Key Technical Specifications

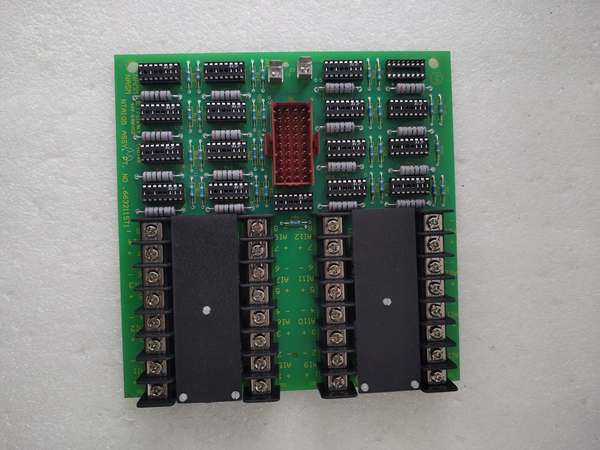

- Model Number: NTAI05

- Manufacturer: ABB

- Compatible Systems: ABB Advant OCS, MasterPiece 200/300 Controllers, Advant Station

- Number of Channels: 8 single-ended channels (4 differential pairs configurable)

- Input Types (Universal): 4–20mA DC, 0–20mA DC, 0–10V DC, ±5V DC, thermocouple (J/K/T/E/R/S), RTD (Pt100/Ni100)

- Resolution: 12-bit (0.025% of full scale)

- Input Impedance: >1MΩ (voltage inputs), <5Ω (current inputs)

- Operating Temperature: 0°C to +60°C (32°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 1kV AC (channel-to-channel, channel-to-backplane)

- Power Supply: Derived from Advant controller backplane (5V DC logic, 24V DC signal)

- Sampling Rate: 5 samples/second per channel (fixed)

- Dimensions (W x H x D): 100mm x 160mm x 120mm

- Weight: Approx. 450g

- Mounting: Rack-mount (Advant controller I/O rack, tool-less installation)

- Protection Features: ESD protection (±12kV), over-voltage protection (up to 30V DC)

- Compliance: IEC 61131-2, IEC 61000-4 (EMC), UL 508

- Status Indicators: Power (PWR), Module OK (GREEN), Fault (RED)

ABB NTAI05

Field Application & Problem Solved

In industrial facilities with legacy control systems—refineries, pulp mills, and power plants operating ABB Advant OCS—the biggest challenge is maintaining reliable analog input measurement for critical process variables. Aging analog modules suffer from component degradation, limited spare availability, or inability to interface with newer sensors, leading to inaccurate readings, unplanned downtime, or costly full-system upgrades. This module solves that by serving as a drop-in replacement for failed legacy analog input modules, maintaining compatibility with existing Advant controllers while supporting a wide range of sensor types—eliminating the need for expensive DCS overhauls.

You’ll typically find this module in Advant OCS I/O racks monitoring core process variables: refinery crude distillation column temperature sensors, pulp mill digester pressure transmitters, or power plant boiler feedwater flow meters. It’s also used in chemical plant batch reactors (pH and level sensors) and water treatment plant turbidity monitors, where replacing the entire DCS is impractical due to cost or operational disruption. For retrofits, it’s the go-to spare for aging Advant systems, extending the life of reliable control infrastructure without sacrificing measurement accuracy.

Its core value is compatibility and longevity. The universal input design supports legacy and modern sensors alike, reducing spare part inventory (one module replaces multiple specialized units). Its rugged construction withstands the same harsh industrial environments as the original Advant system, while the 12-bit resolution maintains the process control precision required for stable operations. For plant operators, this translates to extended system lifespan, reduced maintenance costs, and minimized downtime—critical in facilities where legacy DCS systems still perform reliably but need component replacements.

Installation & Maintenance Pitfalls (Expert Tips)

Channel Configuration: Use MasterPiece Software (Not Guesswork)

Rookies often skip configuring channels via ABB’s MasterPiece software, leaving them at default settings (typically 4–20mA). Connecting a thermocouple or RTD to an unconfigured channel results in nonsensical readings. Always load the original module’s configuration from the controller backup before installing the NTAI05. If no backup exists, use MasterPiece to set each channel’s input type (e.g., Type K thermocouple, Pt100 RTD) to match the connected sensor. Test with a signal generator if the sensor is disconnected—this avoids chasing phantom calibration issues.

Wiring: Differential vs. Single-Ended Matters

The module’s 8 channels can be configured as 4 differential pairs or 8 single-ended inputs, but technicians frequently mix wiring types. Single-ended wiring (common ground) is prone to noise in long runs, while differential wiring (separate signal paths) rejects interference. Use differential configuration for sensor runs over 10m or in high-EMI areas (near motors/transformers). Keep single-ended wiring under 10m and ensure a clean common ground—mixed configurations cause cross-talk and erratic readings.

Thermocouple Cold Junction Compensation: Don’t Bypass It

For thermocouple inputs, the module relies on internal cold junction compensation (CJC) to maintain accuracy. Rookies often disable CJC or ignore wiring polarity, leading to temperature errors of ±5°C or more. Ensure thermocouple wires are connected with correct polarity (positive to +, negative to -) and enable CJC in MasterPiece. Avoid mounting the module near heat sources (e.g., cabinet heaters) — CJC accuracy degrades if the module’s ambient temperature fluctuates more than ±2°C.

Backplane Insertion: Align with Guide Pins (No Forcing)

The Advant I/O rack’s guide pins are critical for proper backplane alignment, but rookies often force the module past misaligned pins. Bent pins or partial seating cause intermittent communication drops or complete module failure. Align the module’s slots with the rack’s guide pins and slide it gently until it seats flush. Listen for a soft “click” from the locking tab—never tap the module with tools. Damaged backplane pins are costly to repair and can disable an entire I/O rack slot.

ABB NTAI05

Technical Deep Dive & Overview

The ABB NTAI05 is a legacy-compatible analog input module engineered to integrate with ABB’s Advant OCS control systems, serving as a critical link between field sensors and the master controller. At its core, it uses 12-bit analog-to-digital converters (ADCs) per channel to convert raw sensor signals into digital data the Advant controller can process. The universal input circuitry adapts to different sensor types via software configuration, eliminating the need for hardware jumpers or adapter modules.

The module’s design prioritizes compatibility with legacy systems: it interfaces seamlessly with Advant MasterPiece 200/300 controllers via the system backplane, using the same communication protocol as original Advant analog modules. This means no controller firmware updates or software modifications are needed—simply remove the failed module and insert the NTAI05. The 1kV isolation between channels and backplane prevents ground loops, a common issue in older industrial wiring systems with multiple grounded devices.

For thermocouple inputs, internal cold junction compensation circuitry corrects for temperature variations at the module’s terminals, ensuring accurate temperature readings without external reference junctions. RTD inputs benefit from built-in current excitation and linearization, converting raw resistance values into calibrated process variables. The fixed 5 samples/second per channel sampling rate matches the Advant controller’s processing capabilities, avoiding data overflow or underflow.

Ruggedness is consistent with industrial legacy standards: the module’s enclosure resists dust and minor moisture, while the 0°C to +60°C operating range handles unconditioned control cabinets. The status LEDs (Power, Module OK, Fault) provide basic troubleshooting visibility—no specialized tools are needed to confirm the module is receiving power and communicating with the controller.

Overall, the NTAI05 is a purpose-built legacy support module. It doesn’t add new features but excels at maintaining the reliability and functionality of aging Advant OCS systems. Its compatibility, ruggedness, and universal input design make it an indispensable spare for facilities relying on legacy ABB control infrastructure to keep critical processes running.