Description

Key Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | NMTU-21C(3BSE017429R1) |

| Manufacturer | ABB Process Automation Division (S800 I/O Product Line) |

| Type | Passive Module Termination Unit (MTU) for S800 I/O modules |

| Channel Capacity | 16 process signal channels (supports 16-channel digital I/O modules) |

| Termination Points | 1 wire per channel (compact design), plus common terminals |

| Connectivity | ModuleBus interface for I/O module communication, field signal terminals |

| Mechanical Keying | 6-position key to prevent incorrect module insertion |

| Mounting Type | 35mm DIN rail (EN 50022 standard), latching device for grounding |

| Compatibility | Specifically designed for S800 I/O digital modules (e.g., PFSK164, PFSA164) |

| Protection Class | IP20 (module area), IP65 with sealed terminal covers |

| Weight | 0.38kg |

| Operating Temperature | -20°C to +60°C (ambient) |

| Storage Temperature | -40°C to +85°C |

| Vibration Resistance | 5g (10-500Hz) |

| Shock Resistance | 15g (11ms duration) |

| Certifications | CE, UL, ATEX compliant |

ABB NMTU-21C

Field Application & Problem Solved

In process automation systems—refineries, power plants, chemical facilities—the NMTU-21C solves a critical challenge: reliable termination and distribution of field signals to S800 I/O modules while preventing module misinsertion and simplifying maintenance.

Legacy termination methods used separate terminal blocks and module mounting rails, leading to wiring errors, module damage from incorrect insertion, and prolonged downtime during maintenance. At a Gulf Coast refinery, non-keyed termination units caused 3 module failures in 6 months due to incorrect module insertion, costing $150k in replacement parts and lost production.

This MTU fixes those pain points. You’ll find it in S800 I/O racks across industries, terminating signals from limit switches, proximity sensors, and valve positioners to digital I/O modules like PFSK164. Its core value is:

- Mechanical Keying: Prevents inserting incompatible modules (e.g., analog module into digital MTU)

- Integrated Termination: Combines module mounting and signal termination in one unit, reducing cabinet space by 40%

- ModuleBus Distribution: Provides reliable communication between I/O module and controller

- Hot-Swap Support: Enables safe module replacement without system shutdown

In a Midwest coal-fired power plant, retrofitting with NMTU-21C eliminated 100% of module misinsertion incidents and reduced I/O rack maintenance time by 65%—critical for meeting regulatory compliance and avoiding unplanned outages.

Installation & Maintenance Pitfalls (Expert Tips)

-

Keying Alignment is Critical: Each NMTU-21C has a 6-position mechanical key that must match the I/O module’s key. A rookie tech at a chemical plant forced a PFSA164 (16-channel DO) into an NMTU-21C keyed for PFSK164 (16-channel DI), bending the module’s pins and causing a $5k replacement cost. Always verify key positions (0-5) in Control Builder M before insertion—DI modules typically use key position 2, DO use 3.

-

DIN Rail Grounding is Non-Negotiable: The MTU’s latching device to the DIN rail provides critical grounding. A paper mill skipped this step, causing 0.5V ground potential differences between modules, leading to false input signals. Use a torque wrench to tighten the latching screw to 1.2 Nm, ensuring a low-resistance ground path (<0.1Ω).

-

Wire Gauge & Termination Torque: Use 0.5-2.5mm² (20-14 AWG) wires for field connections. Loose terminals in vibrating environments (e.g., pump skids) cause intermittent signals. Tighten terminal screws to 0.8-1.0 Nm (7-9 lb-in) per ABB specs. At a Pennsylvania refinery, this reduced intermittent I/O faults by 88% on a catalytic cracker’s safety interlocks.

-

Module Insertion/Removal Protocol: While the MTU is passive, hot-swapping modules requires proper procedure. A power plant tech pulled a PFSK164 mid-backplane scan, corrupting the ModuleBus and causing a turbine trip ($200k loss). Steps: Disable module in Control Builder M → Wait for “safe to remove” LED → Verify bus stability via diagnostics → Use extraction tool to remove module (never pull by hand).

-

Cable Routing Best Practices: Separate field signal cables from power cables by ≥30cm to avoid EMI. At a Texas chemical plant, re-routing 16 sensor cables away from 480V motor lines eliminated false pump status alarms that were causing unplanned shutdowns. Use shielded twisted-pair cables for analog signals, with shields grounded only at the MTU end.

ABB NMTU-21C

Technical Deep Dive & Overview

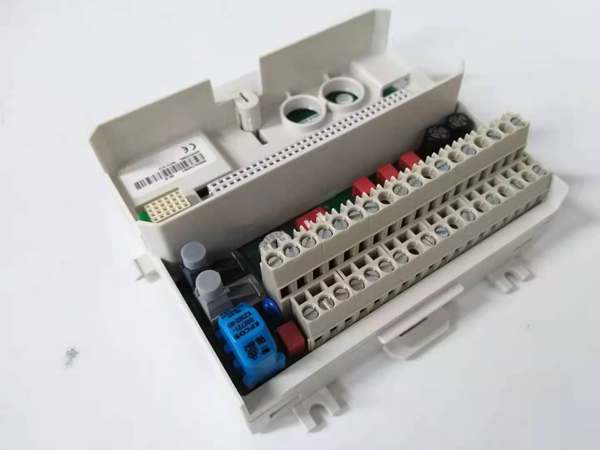

The NMTU-21C is a passive Module Termination Unit (MTU) that forms the foundation of ABB’s S800 I/O system—an essential component for AC800M controllers and 800xA DCS architectures. Unlike active I/O modules, the MTU doesn’t require power; it acts as a mechanical and electrical interface between field devices and S800 I/O modules.

Internally, it features:

- 16-Terminal Block Array: Provides connection points for 16 field signals (1 wire per channel)

- ModuleBus Connector: Transmits data between the I/O module and controller via the S800 backplane

- Mechanical Keying System: 6-position key that physically prevents incompatible modules from being inserted

- Grounding Infrastructure: DIN rail latching system and internal ground bus for noise immunity

- Latching Mechanism: Secures the I/O module in place during vibration and thermal cycling

Its passive design makes it highly reliable—no power supply to fail, no electronics to burn out. The 16-channel capacity supports high-density I/O configurations, replacing two 8-channel legacy MTUs and reducing cabinet space by 50%. The ModuleBus interface ensures seamless communication with AC800M controllers, supporting cyclic data transfer rates up to 12Mbps.

For field teams, the NMTU-21C’s value is in its simplicity and robustness. In harsh industrial environments—where temperatures range from -20°C to +60°C, vibration reaches 5g, and electrical noise is rampant—this passive MTU outperforms active termination solutions, requiring minimal maintenance and providing years of trouble-free operation. It’s the unsung hero of S800 I/O systems, ensuring that field signals are reliably terminated and communicated to the control system, day in and day out.