Description

Key Technical Specifications

- Model Number: NMBA-01 3BHL000510P0003

- Manufacturer: ABB Drives & Controls

- Communication Interface: 1× RS-485 port (2-wire half-duplex; screw terminal connection)

- Protocol Support: Modbus RTU (master/slave configurable), ABB DriveCom

- Data Transfer Rate: 300 bps – 115.2 kbps (software-configurable via drive parameters)

- Max Nodes per Bus: 32 ACS800 drives (when configured as Modbus slave)

- Isolation Rating: 2500V AC (RS-485 port to drive control board)

- Power Supply: 24VDC ±10% (derived from ACS800 drive internal power; 0.08A max current draw)

- Operating Temperature: -10°C to +50°C (14°F to 122°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP20 (module; depends on drive enclosure for field protection)

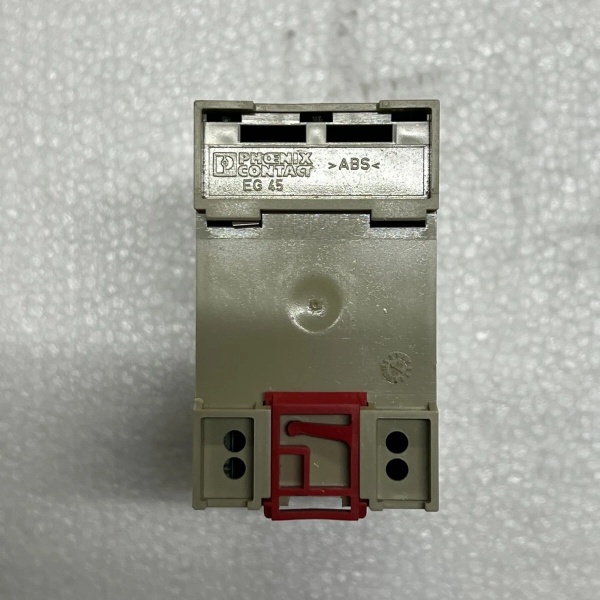

- Mounting: DIN-rail mount (fits inside ACS800 drive control compartment or external enclosure)

- Certifications: UL 508C, CE, IEC 61800-5-1

ABB NMBA-01 3BHL000510P0003

Field Application & Problem Solved

In industrial drive systems, the biggest pain point for remote control and monitoring is integrating ACS800 drives with legacy PLC/DCS systems that rely on Modbus RTU. Without a dedicated communication adapter, technicians are forced to use hardwired I/O for speed setpoints and fault signals—this requires extensive wiring, limits flexibility, and makes it impossible to access detailed drive diagnostics (e.g., current, torque, fault codes). A Midwest water treatment plant once ran 20 separate control wires to each of its 8 pump drives, costing $15k in wiring and labor, and still couldn’t monitor drive temperature remotely.

The NMBA-01 solves this by acting as a plug-and-play Modbus RTU bridge between ACS800 drives and PLC/DCS systems. You’ll find it in wastewater treatment plants controlling pump drives, in HVAC systems managing fan speeds, and in conveyor lines regulating motor torque—any application where remote drive control and diagnostics are critical. Its core value is eliminating hardwired control loops: a single RS-485 cable can connect up to 32 drives to a PLC, reducing wiring costs by 70% and enabling real-time access to 50+ drive parameters. At the water treatment plant, replacing hardwired I/O with NMBA-01 adapters cut wiring time by 80% and let operators monitor drive health remotely, preventing 3 unplanned pump outages in the first year.

Another critical value is 2500V AC isolation, which blocks voltage surges between the drive and PLC—common in plants with unstable power grids. I’ve seen the NMBA-01 survive a lightning-induced surge that fried a non-isolated communication card, keeping the pump drives online and avoiding a plant-wide flood.

Installation & Maintenance Pitfalls (Expert Tips)

Modbus Address Must Be Unique Per Drive: Rookies leave all NMBA-01 adapters set to the default Modbus address (1), causing bus conflicts that take the entire drive network offline. Use the ACS800 drive’s control panel to assign a unique address (1–32) to each NMBA-01—this 2-minute setting prevents 90% of Modbus communication faults. A packaging plant’s conveyor system crashed when 6 drives shared the same address; assigning unique addresses restored communication instantly.

RS-485 Termination Resistor Is Mandatory for End Nodes: The NMBA-01 has a built-in 120-ohm termination resistor jumper—enable it only if the drive is the first or last device on the RS-485 bus. Leaving it enabled on mid-bus drives creates signal reflections; disabling it on end nodes causes data corruption. A cement plant’s fan drive network had 50% packet loss until the termination jumpers were set correctly—one enabled at each end of the bus, all others disabled.

Drive Parameter Lock Prevents Accidental Configuration Changes: Technicians configure the NMBA-01’s baud rate and protocol correctly, then accidentally overwrite the settings via the drive panel. Lock the drive’s communication parameters (parameter group 50) after setup—this prevents unauthorized changes that break Modbus communication. A mining operation’s hoist drive lost communication after a technician adjusted a drive parameter; locking the communication group solved the problem permanently.

Cable Routing Avoids High-Voltage Interference: RS-485 cables routed parallel to 480V motor leads pick up EMI, causing intermittent Modbus timeouts. Run RS-485 cables in separate conduit or cable trays, at least 30 cm away from high-voltage wiring. Use twisted-pair shielded cable and ground the shield at the PLC end only to avoid ground loops. A food plant’s mixer drive network dropped communication daily until the RS-485 cables were rerouted away from motor power lines.

ABB NMBA-01 3BHL000510P0003

Technical Deep Dive & Overview

The ABB NMBA-01 3BHL000510P0003 is a compact RS-485 communication adapter engineered specifically for ACS800 drives, designed to enable seamless Modbus RTU integration with PLC/DCS systems. At its core, a low-power microcontroller handles protocol translation: it converts the drive’s internal DriveCom protocol to Modbus RTU for the PLC, and translates Modbus speed setpoints and control commands back to the drive’s control board. The microcontroller’s firmware is optimized for minimal latency—speed setpoint changes are transmitted to the drive in <10 ms, critical for high-speed applications like conveyor lines.

The module’s 2500V AC galvanic isolation is achieved with optocouplers in the RS-485 signal path, blocking voltage surges and ground potential differences between the drive and PLC. This isolation is a key advantage over non-isolated adapters, which are prone to damage in noisy industrial environments. The NMBA-01’s DIN-rail mount design lets it fit inside the ACS800 drive’s control compartment, eliminating the need for external enclosures and reducing installation space.

Unlike generic Modbus gateways, the NMBA-01 integrates directly with the ACS800’s parameter system—no custom configuration software is needed. All communication settings are adjusted via the drive’s front panel or DriveWindow software, making setup straightforward for technicians familiar with ACS800 drives. The module supports both Modbus master and slave modes: slave mode for PLC control of the drive, master mode for the drive to communicate with other Modbus devices (e.g., pressure sensors). Built with industrial-grade components, the NMBA-01 is rated for 15+ years of operation in harsh drive environments, making it a reliable bridge between ACS800 drives and plant control systems.