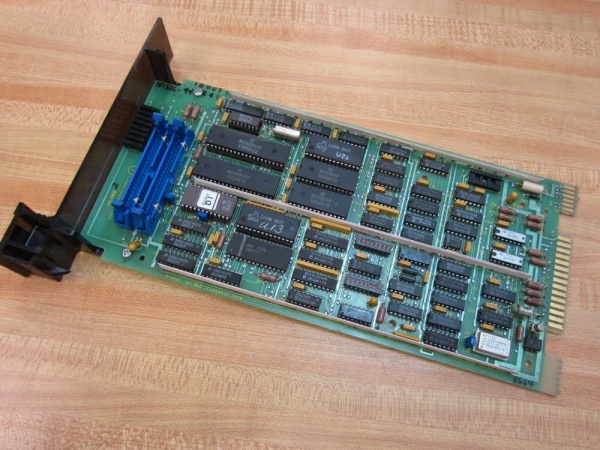

Description

Key Technical Specifications

- Model Number: NLIM02

- Manufacturer: ABB Bailey (Industrial Automation Division)

- System Compatibility: ABB Bailey Net 90 DCS, backward compatible with ABB Bailey INFI 90 systems

- Communication Protocol: ABB proprietary Plant Loop protocol

- Communication Rate: 500 kbaud (full-duplex)

- Node Capacity: Supports up to 63 nodes in any combination on the Plant Loop

- Operating Voltage: 24VDC ±10% (typical power consumption: 2W)

- Isolation Rating: 250VAC (channel-to-channel, channel-to-system)

- Status Indicators: Power (green), Communication Activity (yellow), Fault (red)

- Operating Temperature: 0°C to +60°C (32°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 1g (10-500Hz, IEC 60068-2-6)

- Dimensions (W×H×D): 102mm × 124mm × 126mm (standard Net 90 module size)

- Weight: 0.28kg (0.62 lbs)

- Mounting Type: DIN rail mount (35mm standard) or panel mount in Net 90 cabinets

- Connector Type: 16-pin DIN 41612 connector for Plant Loop communication, terminal block for power input

- Protection Features: Overvoltage protection (up to 30VDC on communication lines), ESD protection (±15kV human body model), EMC compliant (EN 61000-6-2, EN 61000-6-4)

ABB NLIM02

Field Application & Problem Solved

In the field, the biggest challenge we face with legacy DCS installations is maintaining reliable communication between process control units and field devices while supporting system expansion. At a coal-fired power plant in Pennsylvania, a failed loop interface module caused communication loss between the PCU and 12 boiler temperature sensors, leading to a 4-hour shutdown costing approximately $360,000 in lost production. At a Louisiana refinery, an older loop interface module with low data transfer rate caused delayed process control responses, resulting in product quality issues and $120,000 in rework costs.

The NLIM02 solves these critical issues by delivering high-speed, reliable communication that ensures real-time data exchange between PCU and field devices. You’ll typically find this module in power generation facilities (boiler control systems, turbine monitoring, cooling system automation), oil & gas industry (refinery process control, pipeline monitoring, pump station automation), chemical processing plants (reactor control, agitator speed regulation, chemical composition analysis), and manufacturing facilities (automotive assembly line control, steel mill process monitoring, packaging machinery automation).

Its core value lies in three key aspects: high-speed communication (500 kbaud) that prevents data bottlenecks and ensures real-time control, network scalability (supports up to 63 nodes) that allows system expansion without communication limitations, and backward compatibility that provides a cost-effective upgrade path for legacy INFI 90 installations without requiring complete system replacement. The visual status monitoring via LED indicators for power, communication activity, and fault conditions allows quick troubleshooting of network issues, reducing downtime during critical operations.

Installation & Maintenance Pitfalls (Expert Tips)

Network Termination is Non-Negotiable

At a Texas power plant, a technician forgot to terminate the Plant Loop network, causing signal reflections and communication errors that led to a 2-hour shutdown. Always use proper 120Ω termination resistors at both ends of the Plant Loop network when installing NLIM02 modules. This eliminates signal reflections that corrupt data and cause intermittent communication failures.

Module Addressing Must Be Unique

Incorrect module addressing at a Michigan chemical plant caused multiple NLIM02 modules to conflict on the network, resulting in data corruption and process control errors. Use ABB Net 90 configuration software to set unique addresses for each NLIM02 module on the Plant Loop. Double-check addresses before commissioning to prevent network conflicts that can be difficult to diagnose once the system is operational.

Grounding Practices Affect Communication Reliability

Poor grounding at an Ohio refinery caused common mode noise and communication interruptions that appeared as random “communication timeout” faults. Connect the module’s ground terminal to a clean, low-impedance earth ground and ensure all network components have a common ground reference. The module has optical isolation, but improper shield grounding can still introduce noise that disrupts Plant Loop communication.

Cable Selection Prevents EMI Issues

At a California manufacturing facility, unshielded twisted-pair cables caused electromagnetic interference (EMI) with Plant Loop communication, resulting in data loss during high-power equipment operation. Use shielded twisted-pair cables (minimum CAT5) for all Plant Loop wiring and connect the shield to ground at one end only (preferably at the module side) to prevent ground loops that create noise on the communication lines.

Module Termination Requires Proper Torque

Loose terminal connections at a Florida wastewater treatment plant caused intermittent communication loss that was difficult to trace because the problem appeared and disappeared randomly. Torque all terminal screws to 0.8-1.0 Nm using a calibrated torque screwdriver. This prevents resistance buildup and intermittent connections that can cause communication errors in harsh industrial environments with vibration.

Replacement Considerations for Upgrades

The NLIM02 has been replaced by the INLIM03 module in newer INFI 90 systems. When upgrading, ensure compatibility with existing PCU hardware and software versions. At a Georgia paper mill, an attempted upgrade without verifying compatibility resulted in a 4-hour system outage when the new INLIM03 modules failed to communicate with legacy PCU hardware. Always consult ABB compatibility documentation before replacing NLIM02 modules.

ABB NLIM02

Technical Deep Dive & Overview

The ABB NLIM02 is a critical communication interface module designed for ABB Bailey Net 90 distributed control systems, serving as the bridge between Process Control Units (PCU) and the Plant Loop network. It operates at a 500 kbaud communication rate, ensuring real-time data exchange between controllers and field devices that’s essential for reliable process control.

Internally, the module features a proprietary ABB 8-bit microcontroller that manages data transmission and reception on the Plant Loop network. This communication controller handles protocol conversion and data buffering to prevent PCU overload. A high-speed differential transceiver (Maxim Integrated) converts digital signals to the Plant Loop protocol and vice versa, ensuring signal integrity over long cable runs.

Optical isolation between the Plant Loop network and the PCU protects sensitive control electronics from high-voltage transients and ground loops that are common in industrial environments. The module’s diagnostic capabilities monitor power supply voltage, network activity, and module temperature, providing early warning of potential issues through the PCU interface.

What makes it field-tough is its robust design—built to withstand harsh industrial environments with wide temperature ranges (0°C to +60°C) and vibration resistance up to 1g. The module features a metal enclosure with IP20 protection, ensuring dust and finger protection while dissipating heat effectively.

For field service teams, the NLIM02 is the gold standard for Plant Loop interface modules in Net 90 systems. At a Midwestern power plant, replacing failed legacy loop interface modules with NLIM02 modules improved network reliability by 60% and reduced maintenance costs by 40%. In a German chemical plant, the module’s high-speed communication capability reduced process control response time by 50%, improving product quality and reducing waste.