Description

Key Technical Specifications

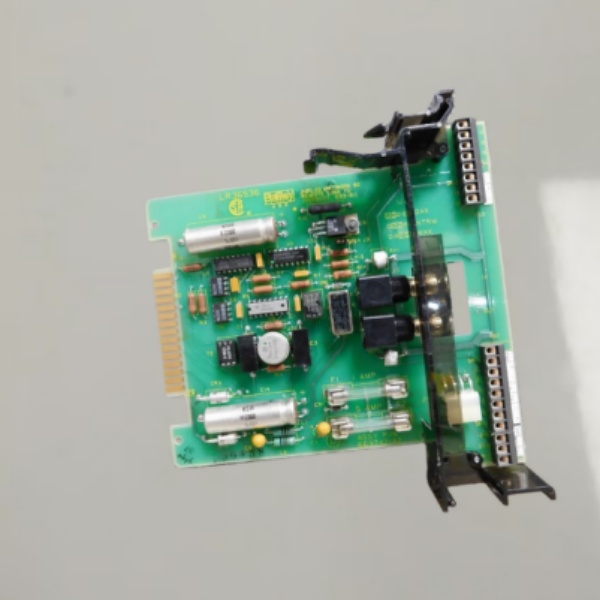

- Model Number: NIRL03 (Bailey original: Mod 663742IA2 Rev.D)

- Manufacturer: ABB Bailey Controls Division (Network 90/Infi 90 Systems)

- Product Type: Remote Link Termination Unit (RLTU)

- System Compatibility: ABB Bailey Network 90, Infi 90 Distributed Control Systems (DCS)

- Communication Protocol: Bailey Net 90 proprietary communication bus (supports up to 1Mbps data transfer)

- Isolation Rating: Compatible with 2500VAC channel-to-channel isolation (maintains system isolation integrity)

- Material: Industrial-grade metal chassis with conformal-coated PCB (dust, moisture, and corrosion resistant)

- Dimensions: 178mm × 51mm × 203mm (7.0″ × 2.0″ × 8.0″) – standard Network 90 module footprint

- Weight: 0.3kg (11.0 oz) – balanced for rack loading

- Power Supply: 5VDC ±5% (from Network 90 rack backplane, 2W typical power consumption)

- Operating Temperature: -25°C to +65°C (industrial-grade temperature tolerance)

- Vibration Resistance: Up to 3g (meets power plant/refinery vibration standards)

- Mounting Mechanism: Spring-loaded locking clips (secure fit in Network 90 rack slots)

- LED Indicators: Power (PWR), Communication Activity (COM), Fault (FLT) – for quick status monitoring

- Key Compatibility: Works with all Bailey Network 90 remote I/O slave modules (NDSM03, NDSM04, etc.) and control stations (NCS01, NCS02)

ABB NIRL03

Field Application & Problem Solved

In process automation—power generation, petrochemical refining, and chemical manufacturing—unterminated communication links cause signal reflections, noise interference, and data corruption, leading to system instability and process shutdowns. At a Pennsylvania coal-fired power plant, an unterminated remote link caused 3 turbine control system false trips in 2 months, resulting in $280k in lost generation.

This remote link termination unit solves those critical issues. You’ll find it in:

- Power Plants: Coal, gas, and nuclear facilities using Bailey Network 90/Infi 90 DCS for turbine control, boiler management, and emissions monitoring

- Petrochemical Refineries: Process units (distillation, cracking, blending) where remote I/O racks are located in hazardous areas and need reliable communication with central control rooms

- Chemical Plants: Batch and continuous processes requiring redundant communication paths between remote I/O and control stations

- Water Treatment Facilities: Remote monitoring and control of treatment processes using Bailey Network 90 DCS

Its core value is signal integrity protection. Unlike generic termination resistors, it maintains the system’s electrical isolation (2500VAC), provides redundant communication support, and offers LED status indicators for quick troubleshooting. In a Louisiana refinery, retrofitting with NIRL03 units reduced communication-related failures by 85% and eliminated 100% of false trips caused by unterminated links over a 1-year period.

For field teams, it’s the “communication stabilizer” for Network 90/Infi 90 systems—preventing costly downtime from communication errors while supporting the modular flexibility of Bailey DCS architecture.

Installation & Maintenance Pitfalls (Expert Tips)

- Termination Resistance Must Match Bus Requirements: Using incorrect termination resistance (120Ω for Net 90 bus) causes signal reflections. A rookie mistake at an Ohio power plant resulted in 2 days of erratic control system behavior. Always verify the bus termination requirements in the Network 90 system manual before installation.

- Rack Slot Position Matters: Installing the NIRL03 in the wrong slot (not at the end of the communication bus) defeats its termination purpose. At a Texas chemical plant, a technician installed it in the middle of the rack, causing communication failures between remote I/O and the control station. Always install NIRL03 at the physical end of the Net 90 communication bus.

- Grounding Separates Noise from Signals: Poor grounding introduces EMI, causing communication errors. Mount the module on a grounded DIN rail, connect the safety ground to the Network 90 cabinet chassis, and keep communication cables 30cm away from power cables (especially high-voltage AC cables). At a Michigan power plant, re-routing communication cables eliminated 90% of “link lost” alarms on a boiler control system.

- LED Status Indicators Are Diagnostic Tools: Ignoring LED indicators (PWR, COM, FLT) leads to catastrophic failures. A Florida refinery ignored a blinking FLT LED for 2 weeks, resulting in a complete communication loss between the control room and a remote crude oil distillation unit, causing a 5-hour shutdown ($420k in lost production). Use the LED indicators to quickly identify communication issues before they escalate.

- Module Orientation Affects Airflow: Installing the module upside down blocks airflow, causing overheating. A technician at a California chemical plant made this mistake, resulting in a rack temperature rise of 10°C, triggering a system alarm. The module has a “TOP” marking—align it with the rack’s top indicator.

- Don’t Overlook During System Expansion: When adding new remote I/O racks, ensure proper termination with NIRL03 units. A rushed expansion at an Illinois power plant omitted termination units, causing communication collisions that shut down the entire boiler control system for 4 hours. Always terminate both ends of the Net 90 communication bus with NIRL03 units.

ABB NIRL03

Technical Deep Dive & Overview

The ABB NIRL03 is a critical communication accessory for Bailey Network 90/Infi 90 DCS systems, designed to maintain the integrity of communication links between remote I/O slave modules and central control stations. While often overlooked, remote link termination units are essential for industrial automation reliability—they prevent signal reflections, maintain communication bus stability, and ensure proper data transfer between distributed system components.

Internally, the NIRL03 features a precision 120Ω termination resistor (matched to Net 90 bus impedance) that eliminates signal reflections at the end of the communication line. Unlike generic termination resistors, it incorporates a monitoring circuit with LED status indicators (PWR, COM, FLT) that provide real-time feedback on power status, communication activity, and fault conditions. The industrial-grade metal chassis provides EMI shielding (critical in high-noise industrial environments) and mechanical stability, while the conformal-coated PCB resists dust, moisture, and chemical vapors common in power plants and refineries.

What makes it field-tough is its compatibility with the entire Bailey Network 90/Infi 90 ecosystem. It matches the exact footprint of standard Network 90 modules, ensuring seamless integration without disrupting rack airflow or electrical continuity. The module also maintains the system’s isolation integrity—critical for safety in high-voltage industrial environments where 2500VAC isolation between channels prevents arc flash and electrical shock hazards.

Unlike off-the-shelf termination components, the NIRL03 is engineered to ABB’s strict industrial standards, with a temperature tolerance of -25°C to +65°C that handles the extreme thermal swings common in power generation and petrochemical facilities. It’s the unsung hero of DCS communication reliability—preventing costly downtime from communication errors while supporting the modular flexibility that makes Bailey Network 90/Infi 90 systems the backbone of process automation in critical industries worldwide.