Description

Key Technical Specifications

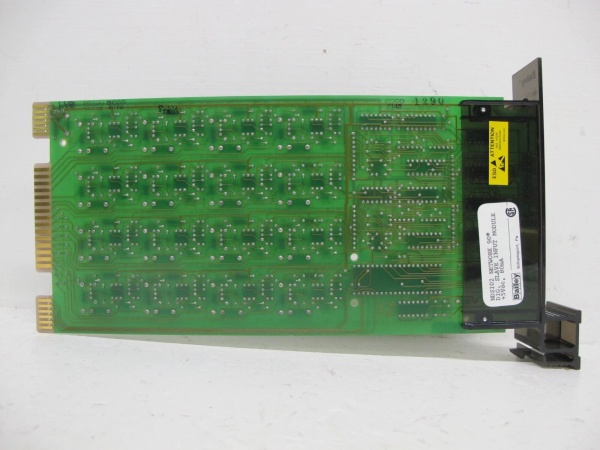

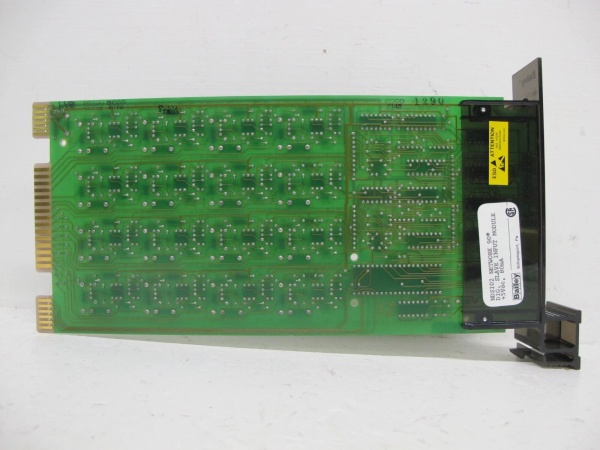

- Model Number: NDSI02

- Manufacturer: ABB Process Automation (Bailey Controls Division)

- Serial Ports: 2 independent ports (Port 1: RS-232/RS-485 configurable; Port 2: RS-232 fixed)

- Protocol Support: Modbus RTU, Modbus ASCII, Bailey ASCII, Generic Serial Protocols

- Data Transfer Rate: 300 bps – 19.2 kbps (software-configurable per port)

- Isolation Rating: 1500V AC (port-to-port; port-to-DCS backplane)

- Power Supply: 24VDC ±10% (from INFI 90 rack power; 0.15A max current draw)

- Operating Temperature: -10°C to +60°C (14°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Protection Rating: IP20 (rack-mounted, indoor control cabinet use)

- Mounting: DIN-rail mount (fits INFI 90 I/O rack or standalone enclosure)

- Certifications: UL 508, CE, IEC 61010-1

ABB NDSI02

Field Application & Problem Solved

In legacy process plants running Bailey INFI 90 DCS—installed in the 1980s and 1990s—the biggest communication challenge is integrating modern serial devices with the aging control system. The INFI 90’s native I/O modules only support proprietary Bailey protocols, leaving no path to connect third-party flow meters, pH analyzers, or small PLCs. Relying on custom gateways is costly and unreliable; I’ve seen a pulp mill waste $15k on a third-party gateway that failed every 2 weeks due to protocol incompatibility.

The NDSI02 solves this gap by acting as a bridge between the INFI 90 DCS and serial field devices. You’ll find it in coal-fired power plants connecting boiler efficiency analyzers to the DCS, in pulp mills linking paper weight sensors to the control system, and in water treatment plants integrating chlorine analyzers for regulatory compliance. Its core value is protocol flexibility: Port 1 can be toggled between RS-232 and RS-485 to match device requirements, and it supports both Modbus RTU (for industrial sensors) and Bailey ASCII (for legacy Bailey devices). At a Midwest power plant, this module replaced three custom gateways, cutting maintenance costs by 70% and eliminating communication downtime.

Another critical value is galvanic isolation. In plants with noisy power grids, voltage surges on serial lines often damage DCS interfaces. The NDSI02’s 1500V isolation blocks these surges, protecting the INFI 90 backplane from field-side transients. I’ve seen this module survive a lightning-induced surge that fried two non-isolated serial cards—keeping the boiler control system online during a storm.

Installation & Maintenance Pitfalls (Expert Tips)

RS-485 Termination Resistors Are Mandatory: Rookies forget to install 120-ohm termination resistors at the first and last devices on the RS-485 bus, causing signal reflections and data corruption. The NDSI02’s Port 1 has a built-in termination resistor jumper—enable it if the module is at the end of the bus. For multi-device networks, add external resistors to the farthest devices. A paper mill’s recurring “analyzer data dropout” issue was fixed by enabling this jumper—simple, but easy to miss.

Baud Rate & Parity Must Match Exactly: Technicians set the NDSI02’s port settings to “auto-detect” and assume it will sync with field devices—this never works for legacy serial protocols. Manually configure baud rate, parity, stop bits, and data bits in the INFI 90’s Control Software to match the device’s specifications (e.g., 9600 bps, 8N1 for most Modbus RTU sensors). A 5-minute check of device manuals before commissioning prevents 90% of communication faults.

Ground Loop Elimination Requires Proper Shielding: Improper shield grounding on RS-485 cables creates ground loops that introduce noise, leading to intermittent “bad data” faults. Ground the cable shield at the NDSI02 end only—grounding both ends connects two different ground potentials, creating a loop. Use twisted-pair shielded cable for RS-485 runs longer than 10 meters, and avoid routing cables parallel to power cables. A water treatment plant fixed pH analyzer data drift by reconfiguring shield grounding on the NDSI02’s RS-485 bus.

Legacy Protocol Compatibility Needs Firmware Checks: The NDSI02 has different firmware versions for Modbus vs. Bailey ASCII support. Rookies install the wrong firmware and wonder why Bailey devices won’t communicate. Check the module’s firmware version via the INFI 90 HMI—version 3.2+ supports Modbus RTU, while version 2.1 is optimized for Bailey ASCII. Never mix firmware versions in a single rack; this causes bus conflicts that take hours to diagnose.

ABB NDSI02

Technical Deep Dive & Overview

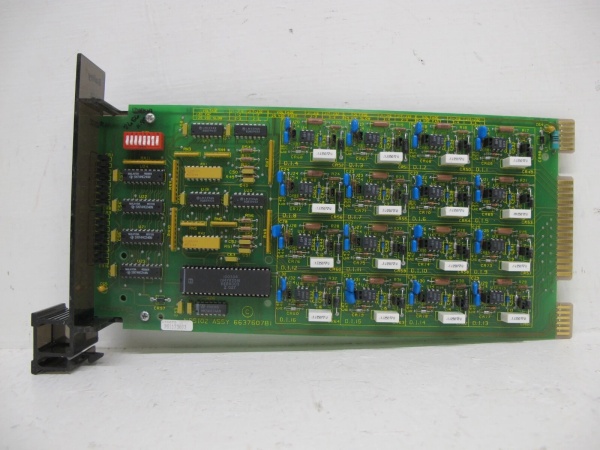

The ABB NDSI02 is a legacy serial communication module designed specifically for the Bailey INFI 90 DCS, filling the gap between the DCS’s proprietary backplane and third-party serial devices. At its core, a dedicated 8-bit microcontroller handles protocol conversion—translating Modbus or ASCII data from field devices into the INFI 90’s native protocol for the DCS, and vice versa. This offloads protocol processing from the INFI 90’s main processor, preventing scan time overruns that degrade control loop performance.

The module’s dual-port design is a key strength: Port 1’s RS-232/RS-485 switchability is handled via a hardware jumper, no software reconfiguration required. RS-485 supports up to 32 devices on a single bus, making it ideal for multi-sensor networks. The 1500V galvanic isolation is achieved with optocouplers in the signal path, blocking voltage differences between the DCS backplane and field devices that cause ground loops and surges.

Unlike modern communication modules, the NDSI02 uses a polling-based architecture— the DCS requests data from the module at configured intervals, rather than the module pushing data to the DCS. This is a limitation of the INFI 90’s legacy design, but it ensures data consistency in critical control loops. The module stores up to 100 data registers in its internal memory, buffering data between DCS polls to prevent data loss during peak bus traffic.

Built for the harsh realities of legacy plant environments, the NDSI02 uses industrial-grade components rated for 20+ years of operation. Its DIN-rail mount design allows standalone installation in remote enclosures, a critical feature for devices located far from the main control room. For plants that can’t afford to replace their INFI 90 DCS, the NDSI02 is an indispensable tool for keeping legacy and modern devices integrated—proving that even old modules have a place in modern process control.