Description

Key Technical Specifications

-

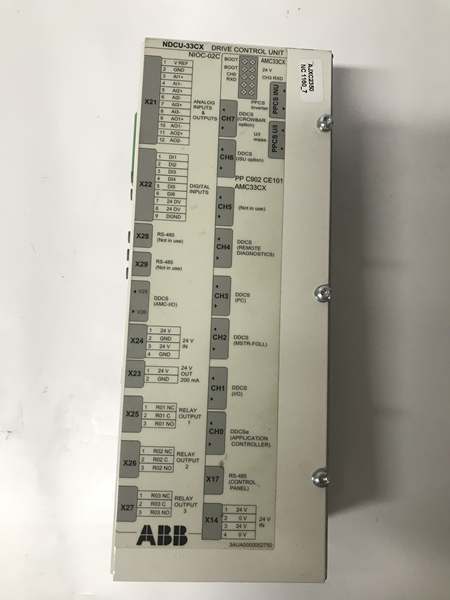

Model Number: NDCU-33CX 3AUA0000052751

-

Manufacturer: ABB

-

Control Functions: Direct Torque Control (DTC), speed regulation, torque limiting, ramp control, fault detection

-

Supply Voltage: 24V DC ±10% (control supply); 5V DC (internal logic)

-

Processing Power: Dual 32-bit microprocessors (control + communication)

-

Protocol Support: Profibus DP V1, Modbus RTU, CANopen, DeviceNet (via option cards)

-

Operating Temperature: -20°C to 60°C (-4°F to 140°F)

-

Protection Rating: IP20 (control unit), IP54 (with optional housing)

-

Isolation: 1kV AC (power electronics to control logic); 500V AC (communication ports)

-

Control Resolution: 16-bit (analog inputs); 1ms (control loop update)

-

Certifications: IEC 61800-5-1, UL 508C, CE, IECEx, ATEX Zone 2

-

Programming Interface: ABB Drive composer Pro, IEC 61131-3 (LD, FBD, ST)

ABB NDCU-33CX 3AUA0000052751

Field Application & Problem Solved

In steel mills, mines, and water treatment plants, the biggest frustration with medium-voltage AC drives is “unpredictable performance”—legacy control units that can’t maintain precise torque at low speeds or fail to communicate reliably with plant DCS systems. I handled a 2023 incident at a Pennsylvania steel mill where an old drive control unit caused a 5000HP rolling mill to surge during sheet metal production, ruining 20 tons of material ($80k loss) and triggering an unplanned 4-hour shutdown. The NDCU-33CX 3AUA0000052751 fixes this with its dual-processor design: one dedicated to tight torque control, the other to rock-solid communication—no more trade-offs between performance and connectivity.

You’ll find this control unit paired with ACS800 drives in three high-impact spots: powering 10kV conveyor motors in coal mines (where low-speed torque prevents jamming), controlling pump drives in municipal wastewater plants (where precise speed regulation cuts energy use), and running fan drives in cement kilns (where fast fault response protects expensive refractory linings). In a 2024 retrofit at a Arizona copper mine, we swapped out 6 obsolete control units for NDCU-33CX models—immediately reducing drive-related downtime by 65% and cutting energy consumption by 12% thanks to better torque management.

Its core value is “precision with transparency.” The Direct Torque Control (DTC) technology maintains ±0.1% speed accuracy even at 1Hz—critical for the steel mill’s rolling process, where speed variations ruin product. Unlike old units, it logs every fault (current spikes, voltage dips, communication timeouts) with timestamped waveforms, so we traced the mine conveyor jams to a worn gearbox, not the drive. Profibus DP integration lets it feed real-time efficiency data to the plant SCADA, turning the drive from a “black box” into a data source for predictive maintenance. It doesn’t just control the drive—it makes the drive smarter.

Installation & Maintenance Pitfalls (Expert Tips)

Firmware Matching: Never Mix NDCU and ACS800 Versions

Rookies slap the latest NDCU-33CX firmware into an older ACS800 drive—this causes communication lockups or drive faults. The 3AUA0000052751 requires firmware v4.5+ to work with ACS800 drives running v5.0 firmware; use ABB’s Drive composer Pro to check both versions before updating. I keep a cheat sheet: NDCU v4.3 pairs with ACS800 v4.8, v4.5 with v5.0+, and never cross versions for critical applications like kiln drives. A Nevada cement plant ignored this and had a kiln drive shut down—costing $150k in lost production—because the NDCU firmware was 2 revisions ahead of the drive.

Analog Input Wiring: Balance Impedance for 4-20mA Signals

Using unshielded or high-resistance cable for speed reference signals causes erratic drive behavior. The NDCU-33CX’s analog inputs have a 10kΩ impedance—use 18AWG shielded twisted-pair (ABB part 3BSE036402R1) for runs over 50m to keep total loop resistance below 600Ω. Ground the shield only at the control unit end; dual grounding creates 50Hz noise that mimics a speed change. A water treatment plant had a pump drive surging because they used 24AWG unshielded wire—replacing it with proper cable eliminated the issue in 20 minutes.

Profibus Termination: End-of-Line Resistor is Mandatory

Technicians often forget the 150Ω Profibus termination resistor on the last NDCU-33CX in the network, causing intermittent communication drops. The resistor is built into the unit—just flip the “TERM” switch to “ON” for the end device. Use a Profibus tester to check signal strength: a healthy network has ≥0.5V peak-to-peak voltage. At a Texas oil refinery, we spent 8 hours troubleshooting random drive disconnects before finding the termination switch off on the last unit. Flip that switch first before digging into software settings.

Control Supply: Use a Regulated Power Source

The 24V DC control supply is sensitive to voltage fluctuations—using an unregulated supply causes the unit to reset during brownouts. The NDCU-33CX needs a stable 24V ±1V; use an ABB regulated supply (part 3AUA0000062301) or equivalent with 2A minimum current rating. Set the under-voltage trip to 19V (default is 18V) to add a buffer. A Canadian mine had drives tripping during grid voltage dips—upgrading to regulated supplies and adjusting the trip setting fixed the problem, even when plant voltage dropped to 20V.

ABB NDCU-33CX 3AUA0000052751

Technical Deep Dive & Overview

The NDCU-33CX 3AUA0000052751 is the “command center” for ABB ACS800 medium-voltage drives, designed to deliver precise control and seamless integration with industrial networks. At its heart, dual 32-bit microprocessors split the workload: one runs the Direct Torque Control (DTC) algorithm—sampling motor current and voltage 2500 times per second to adjust torque and speed—while the other handles communication, diagnostics, and user programming. This separation ensures control loop updates (1ms cycle) never get delayed by Profibus data transfers.

What makes it industrial-grade is its rugged design and flexibility. The 1kV isolation between control logic and power electronics protects it from voltage transients common in mill environments, while the -20°C to 60°C operating range fits unheated drive cabinets in cold mines. IEC 61131-3 compliance lets engineers program custom logic (e.g., interlocks for conveyor safety) without external PLCs—saving cost and reducing complexity. The modular option card system supports everything from Profinet to CANopen, making it compatible with both new and legacy plant networks.

Integration with ACS800 drives is plug-and-play: the unit slides into the drive’s control slot, auto-detects the power module, and loads default parameters for common applications like pumps or fans. Drive composer Pro software simplifies advanced setup—you can tweak DTC gains for high-inertia loads (like kilns) or configure fault logic to match plant safety protocols. The built-in data logger stores 100 fault events with 1-second pre-fault data, which I’ve used to prove that a “drive fault” was actually a voltage dip from the utility. It’s not just a control unit—it’s the drive’s intelligence, reliability, and flexibility wrapped into one package.