Description

Key Technical Specifications

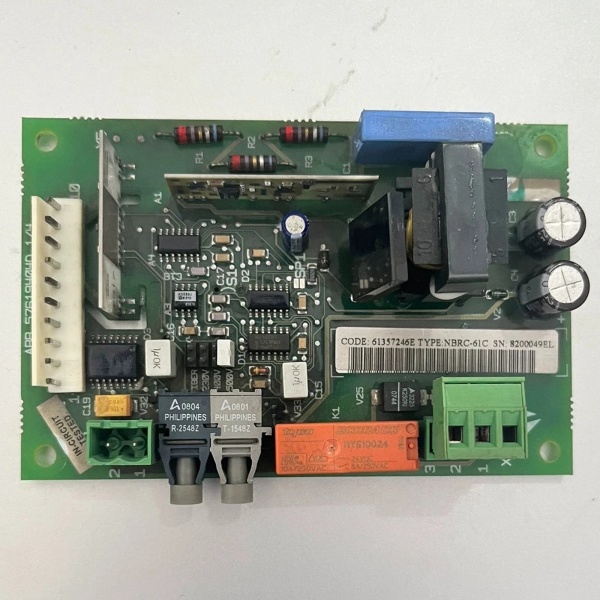

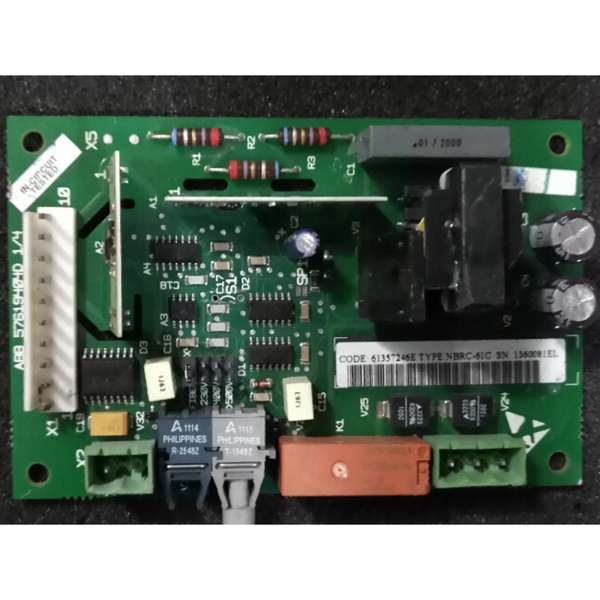

- Model Number: NBRC-61

- Manufacturer: ABB Process Automation

- Protocol Support: Profibus DP V1 (EN 50170), Industrial Ethernet (TCP/IP, UDP)

- Communication Ports: 2 x 10/100 Mbps Ethernet (RJ45, redundant), 1 x Profibus DP (DB9 female)

- Profibus DP Role: Configurable as master or slave; supports up to 124 Profibus DP slaves

- Data Transfer Rate: Up to 12 Mbps (Profibus DP), 100 Mbps (Ethernet)

- Redundancy Support: Hot standby Ethernet ports; automatic failover (<100ms)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation Rating: 500V AC (Ethernet/Profibus ports to backplane)

- Power Supply: 24VDC ±10% (from DCS rack; 0.3A max current draw)

- Mounting: Rack-mounted (fits ABB Advant OCS/AC 800M I/O chassis)

- Diagnostic Indicators: Front-panel LEDs (power, Ethernet link, Profibus status, redundancy active, fault)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

NBRC-61

Field Application & Problem Solved

In refineries, chemical plants, and power stations running ABB Advant OCS or AC 800M DCS, the biggest challenge is integrating legacy Profibus DP field devices (valve positioners, transmitters, motor starters) with modern Ethernet-based controllers. Without a dedicated bridge, data transfer between these networks is slow, unreliable, and requires custom software—leading to scan time overruns and difficulty troubleshooting. The NBRC-61 solves this by acting as a plug-and-play protocol converter: it translates Profibus DP messages to Ethernet TCP/IP (and vice versa) in real time, eliminating compatibility gaps between old and new systems.

You’ll find this module in every ABB DCS installation with mixed Profibus/Ethernet networks—typically in crude distillation units, batch reactor systems, and turbine control loops. It’s the critical link that lets Profibus field devices communicate with the central AC 800M controller, enabling centralized monitoring and control. Its core value is redundancy paired with simplicity: the dual Ethernet ports provide failover protection for critical loops, while the pre-configured protocol stacks eliminate the need for complex programming. I’ve seen this module save a refinery from a $250k shutdown when a primary Ethernet cable was cut— the standby port kicked in instantly, and the process continued without interruption.

Another hidden value is its Profibus master capability. In plants with scattered Profibus devices, the NBRC-61 can act as a local master, polling field devices and sending consolidated data to the DCS controller. This offloads communication tasks from the controller, reducing scan time and improving loop performance. For example, in a chemical plant with 50 Profibus valve positioners, the NBRC-61 polls all devices simultaneously and sends a single data packet to the controller— cutting communication overhead by 70% compared to direct controller polling.

Installation & Maintenance Pitfalls (Expert Tips)

Profibus Termination Is Non-Negotiable: Rookies often forget to install the 120Ω termination resistor at the farthest Profibus device from the NBRC-61. Without it, signal reflection causes data corruption, leading to intermittent “device not found” faults. The resistor must be installed at both ends of the Profibus segment— one at the NBRC-61’s Profibus port (via internal DIP switch) and one at the last slave device. I’ve fixed more Profibus communication issues from missing terminators than any other mistake with this module.

Redundant Ethernet Requires Separate Switches: To get true redundancy, the two Ethernet ports must connect to separate network switches. Rookies connect both ports to the same switch, thinking it’s redundant— but a switch failure will take down both ports. Use two independent switches (one for primary, one for standby) and ensure they’re on separate power circuits. This is the only way to guarantee failover during a network outage. I’ve seen a plant lose Profibus communication for 3 hours because both Ethernet ports were on the same switch that failed.

Profibus Address Conflicts Break Communication: Every Profibus slave device must have a unique address (1–124) that doesn’t conflict with the NBRC-61’s Profibus address (default: 1). Rookies often leave the NBRC-61 at address 1 and assign the same address to a field device, causing a bus collision. Always use a Profibus address scanner to verify uniqueness before commissioning. If you change the NBRC-61’s address, update it in the DCS configuration software— otherwise, the controller won’t recognize the module.

Firmware Mismatch Causes Protocol Errors: When replacing a failed NBRC-61, don’t assume the new module’s firmware matches the old one. Newer firmware versions may have updated Profibus/Ethernet protocol stacks that aren’t compatible with older DCS controller firmware. Check the firmware revision on the old module (via front-panel display or DCS software) and match it with the replacement. If you can’t find a matching version, update the controller firmware first— otherwise, you’ll get “protocol mismatch” faults that are hard to diagnose.

NBRC-61

Technical Deep Dive & Overview

The ABB NBRC-61 is a microprocessor-based network bridge designed to bridge Profibus DP and Industrial Ethernet in ABB DCS systems. At its core, it uses two dedicated processors: one handles Profibus DP communication (including master/slave polling and data buffering), and the other manages Ethernet TCP/IP traffic. This dual-processor design ensures parallel data processing, eliminating bottlenecks even when both networks are heavily loaded.

The module’s redundancy is achieved via hot standby Ethernet ports: the primary port is active, while the standby port monitors network traffic. If the primary port loses link (detected via missing Ethernet frames), the module switches to the standby port in less than 100ms— fast enough to avoid process disruptions. The Profibus DP interface supports both master and slave roles, making it flexible for different network topologies: in master mode, it controls a Profibus segment; in slave mode, it acts as a gateway for a DCS controller to access a remote Profibus network.

Unlike generic protocol converters, the NBRC-61 is fully integrated with ABB’s Control Builder software— all configuration (Profibus address, Ethernet IP, protocol mode) is done via the DCS engineering environment, with no need for third-party tools. The module’s diagnostic engine continuously monitors port status, signal quality, and data transmission errors, sending real-time alerts to the DCS HMI. This includes Profibus fault codes (e.g., address conflict, termination missing) and Ethernet link status, making troubleshooting faster.

The 500V AC isolation between ports and backplane protects the DCS controller from high-voltage surges in the field— common in industrial environments with motor drives or lightning strikes. The module’s rugged metal housing resists vibration and corrosion, and it’s rated for 10+ years of continuous operation. For ABB DCS users, the NBRC-61 is the gold standard for Profibus-to-Ethernet integration— it’s reliable, easy to configure, and built to withstand the harsh conditions of process plants.