Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | NBRA-658C |

| Manufacturer | ABB |

| Product Category | Nuclear Safety Relay Module |

| Safety Certification | IEC 61508 SIL 3, IEEE 384 Class 1E |

| Contact Configuration | 6 Form C (6PDT) |

| Contact Rating | 10A @ 250V AC/30V DC (resistive) |

| Isolation Voltage | 2500 V AC (coil to contacts) |

| Operate/Release Time | ≤15 ms / ≤10 ms |

| Ambient Temperature | -40°C to +85°C |

| Shock Resistance | 100g, 6ms (IEC 60068-2-27) |

| Vibration Resistance | 5g @ 10-500 Hz (IEC 60068-2-6) |

| MTBF | >1,000,000 hours (FMEDA verified) |

| Design Life | 40 years |

ABB NBRA-658C

Product Introduction

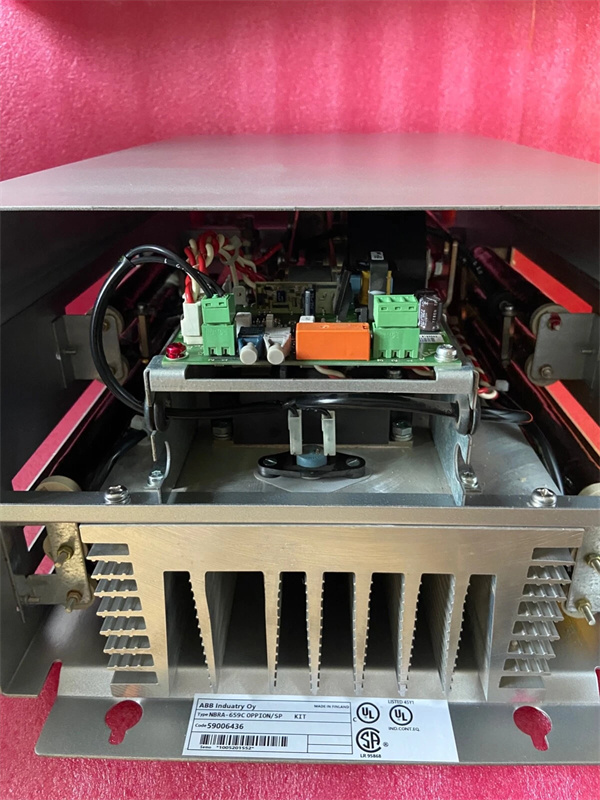

The ABB NBRA-658C is a high-integrity safety relay module engineered for nuclear power applications requiring IEC 61508 SIL 3 certification. As part of ABB’s Nuclear Qualified Relay family, this 6-pole dual-throw (6PDT) device provides fail-safe switching for critical safety instrumented systems (SIS) in reactor protection, emergency cooling, and radiation monitoring. The NBRA-658C features hermetically sealed contacts with arc-quenching chambers, ensuring reliable operation under seismic events (IEEE 344 qualified) and electromagnetic interference (EMC Class A).

Designed for deployment in Class 1E nuclear safety systems, the ABB NBRA-658C undergoes rigorous accelerated aging tests simulating 40+ years of service. Its gold-plated bifurcated contacts maintain <100 mΩ resistance after 100,000 cycles, preventing latent failures. The module integrates with ABB’s Safeguard 800xA platform, enabling real-time contact health monitoring through embedded micro-switch diagnostics.

Core Advantages and Technical Highlights

Ultra-High Reliability:

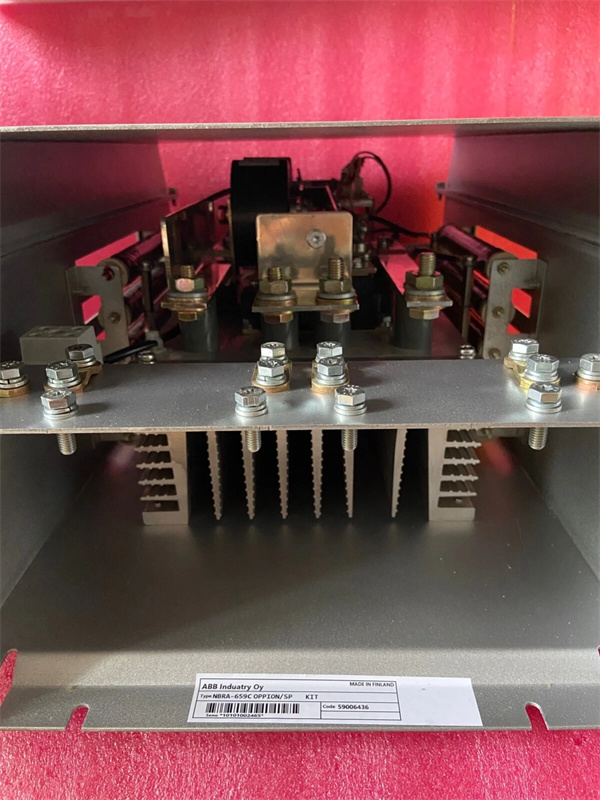

Redundant contact design with forced-guided mechanism (EN 50205) ensures NO/NC state synchronization. Welded construction eliminates screw loosening under vibration. Hermetic sealing prevents sulfurization/corrosion in containment buildings.

Nuclear Environmental Resilience:

Qualified for LOCA (Loss-of-Coolant Accident) conditions: Operates at 150°C/100% RH for 72 hours post-accident. Gamma radiation tolerance: 750 kGy total dose. Seismic certification to 10g ZPA (Zero Period Acceleration).

Diagnostic Capabilities:

Integrated auxiliary contacts provide positive confirmation of main contact status. ABB’s Safeguard Logic Solver continuously monitors contact resistance and actuation timing, triggering alerts for deviations >±5%.

Simplified Maintenance:

Front-accessible test points allow functional verification without disconnection. Replaceable coil assemblies minimize downtime. Zinc-whisker-free materials comply with nuclear data center requirements.

Typical Application Scenarios

In pressurized water reactors (PWR), the ABB NBRA-658C executes reactor trip functions, opening control rod drive circuits within 20 ms of SCRAM signals. Its IEEE 384 Class 1E separation prevents common-cause failures between redundant safety trains.

Nuclear fuel handling systems utilize these relays for crane emergency stops, where hermetically sealed contacts prevent spark-induced ignition in hydrogen-rich environments. Seismic qualification ensures operation during design basis earthquakes (DBE).

Radiation monitoring cabinets deploy the NBRA-658C to isolate contaminated zones by shutting down ventilation dampers. Gamma radiation tolerance maintains functionality post-accident.

ABB NBRA-658C

Related Model Recommendations

NBRA-435C: 4PDT SIL 3 relay for lower-pole applications.

NBPS-110C: Redundant power supply for relay control circuits.

SILA11: ABB’s SIL-certified interface module for logic solver integration.

NBCT-200: Test cabinet for relay performance validation.

3BSE018105R1: Nuclear-grade 24VDC power supply.

NBTA-700: Termination assembly for Class 1E wiring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Maintain ≥50 mm clearance between adjacent relays for heat dissipation. Use silver-plated copper wiring (min 2.5 mm²). Ground chassis to <0.1 Ω with dedicated ground bus. Required tools: Insulated torque screwdriver (0.6 N·m), megger tester (500V DC).

Maintenance Suggestions:

Annual: Measure contact resistance (<150 mΩ) and operate/release timing. Verify coil voltage (20-28 VDC). Every 5 years: Perform dielectric test (2000 V AC, 1 min between contacts). Replace if contact erosion exceeds 50% per ABB NBCT-200 test protocol. Never lubricate contacts.

Service and Guarantee Commitment

ABB provides a 15-year design life warranty for the NBRA-658C, backed by nuclear quality assurance (NQA-1) documentation. Global nuclear support includes:

On-site failure analysis within 72 hours for safety-critical faults

Lifetime technical documentation updates (including PIRT/PIRT reports)

Dedicated nuclear component repair facility (ISO 19443 certified)

All NBRA-658C relays undergo 500-operation burn-in, HALT testing (85°C/85% RH), and seismic simulation before shipment. Extended service agreements include radiation damage assessment and spare-pool management.