Description

Detailed parameter table

| Parameter name | Parameter value |

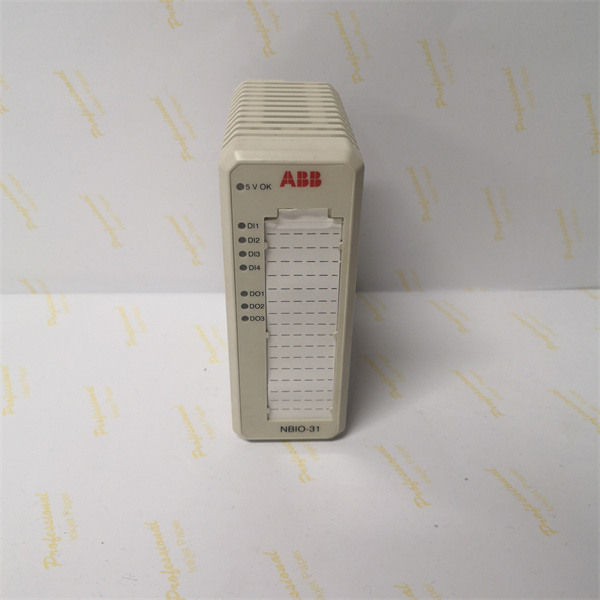

| Product model | NBIO-31 3BSE011337R1 |

| Manufacturer | ABB |

| Product category | Digital input/output module |

| Input channels | 16 digital inputs (24 V DC) |

| Output channels | 16 digital outputs (24 V DC, PNP) |

| Input voltage range | 19.2 V DC to 30 V DC |

| Output current per channel | 0.5 A (max continuous) |

| Total output current | 8 A (max) |

| Response time | Input: <1 ms; Output: <1 ms |

| Isolation | 2.5 kV AC (channels to backplane) |

| Communication | Integrated with ABB AC800M controller backplane |

| Operating temperature | -40°C to 70°C |

| Dimensions | 100 mm × 160 mm × 80 mm |

| Mounting type | Backplane mount (AC800M controller rack) |

| Protection rating | IP20 |

| Certifications | IEC 61131-2, CE, UL, ATEX |

ABB NBIO-31 3BSE011337R1

Product introduction

The NBIO-31 3BSE011337R1 is a high-performance digital input/output module from ABB, designed to serve as a critical interface between field devices and the AC800M controller in industrial automation systems. As a key component of ABB’s Advant OCS and AC800M product families, NBIO-31 3BSE011337R1 combines 16 digital inputs and 16 digital outputs in a single compact unit, enabling efficient monitoring and control of discrete devices such as sensors, actuators, relays, and contactors.

Engineered for reliability in harsh industrial environments, NBIO-31 3BSE011337R1 offers robust isolation and a wide operating temperature range, making it suitable for applications in chemical processing, power generation, and manufacturing. Its fast response time ensures real-time data exchange between field equipment and the controller, while seamless integration with ABB’s Automation Builder software simplifies configuration and diagnostics. Whether used in standalone control systems or integrated into larger DCS architectures, NBIO-31 3BSE011337R1 delivers consistent performance, enhancing the efficiency and responsiveness of industrial automation processes.

Core advantages and technical highlights

High channel density: NBIO-31 3BSE011337R1 packs 16 inputs and 16 outputs into a compact form factor, reducing the required rack space in control cabinets by up to 30% compared to modules with lower channel counts. This density is particularly valuable in space-constrained environments, such as offshore platforms or compact machine control panels, where every centimeter of cabinet space matters. The integrated design also minimizes wiring complexity, as a single module can replace multiple smaller units, streamlining installation and reducing potential points of failure.

Rapid response times: With input and output response times of less than 1 ms, NBIO-31 3BSE011337R1 ensures that critical events—such as a sudden emergency stop signal from a safety sensor—are processed almost instantaneously. In a high-speed packaging line, for example, this speed allows the module to trigger a conveyor stop within milliseconds of detecting a jam, preventing product damage and reducing downtime. The fast response also enables precise synchronization between sequential operations, such as coordinating robotic arm movements with material handling systems.

Robust isolation and durability: NBIO-31 3BSE011337R1 features 2.5 kV AC isolation between channels and the controller backplane, protecting sensitive control electronics from electrical noise, ground loops, and voltage transients common in industrial settings. This isolation is crucial in environments with heavy machinery, such as steel mills or pulp and paper plants, where electromagnetic interference can disrupt signal integrity. Combined with its -40°C to 70°C operating range, the module maintains performance in extreme temperatures, ensuring reliability in unheated warehouses or hot process areas.

Seamless integration with ABB ecosystem: NBIO-31 3BSE011337R1 is natively compatible with ABB’s AC800M controllers and Automation Builder software, enabling plug-and-play configuration and centralized monitoring. The software provides tools for mapping input/output channels to control logic, setting up diagnostics, and simulating operations before deployment—reducing commissioning time by up to 25%. In a water treatment plant, this integration allows operators to monitor valve status (via inputs) and control pump starts/stops (via outputs) directly from the plant’s SCADA system, creating a unified control environment.

Typical application scenarios

In a chemical processing plant, NBIO-31 3BSE011337R1 is integrated into the control system for a batch reactor unit. The module’s 16 inputs monitor the status of pressure relief valves, level switches, and door interlocks, while the 16 outputs control solenoid valves, heater elements, and alarm buzzers. When a high-pressure condition is detected by a pressure switch, the input channel on NBIO-31 3BSE011337R1 sends a signal to the AC800M controller, which immediately triggers an output channel to close the feed valve and activate an alarm—all within milliseconds. The module’s robust isolation prevents electrical noise from nearby pumps from interfering with these critical signals, ensuring safe and reliable reactor operation.

In an automotive assembly line, NBIO-31 3BSE011337R1 coordinates the operation of robotic welding stations. Inputs track the position of car body frames (via photoelectric sensors) and the status of welding torches (e.g., “ready” or “maintenance required”), while outputs control conveyor movement, torch activation, and part clamping mechanisms. The module’s fast response time ensures that the welding torch activates precisely when the frame is in position, reducing cycle times and improving weld quality. Integration with ABB’s Automation Builder allows technicians to quickly reconfigure input/output mappings when switching between vehicle models, supporting flexible manufacturing.

ABB NBIO-31 3BSE011337R1

Related model recommendations

ABB AC800M Controller: The central processing unit that works with NBIO-31 3BSE011337R1 to execute control logic and process input/output data.

ABB CI627A 3BSE017457R1: A communication module that enables NBIO-31 3BSE011337R1 to exchange data with remote devices via PROFIBUS.

ABB DSCA114 57510001-AA: An analog input module that complements NBIO-31 3BSE011337R1 by handling continuous signals (e.g., temperature, pressure) in mixed-signal systems.

ABB DSAO120 57120001-EY: An analog output module that pairs with NBIO-31 3BSE011337R1 to control variable-speed drives or control valves.

ABB TB857: A surge protection terminal block that safeguards NBIO-31 3BSE011337R1’s input channels from voltage spikes in industrial environments.

ABB 200900-004: A terminal block used to terminate field wiring for NBIO-31 3BSE011337R1’s input and output channels.

Installation, commissioning and maintenance instructions

Installation preparation: Mount NBIO-31 3BSE011337R1 into the AC800M controller rack, ensuring proper alignment with the backplane connector. Secure the module with the front panel screw, torquing to 0.5 Nm. Connect field devices to the input/output terminals using 0.5 mm² to 1 mm² shielded twisted-pair cable, with separate runs for inputs and outputs to minimize crosstalk. Ground the cable shields at the module end using the dedicated grounding terminal. Power off the controller rack during installation, and verify that the field power supply (24 V DC) is within the 19.2 V to 30 V range before energizing. Use a torque screwdriver set to 0.5 Nm for terminal connections to ensure proper contact.

Maintenance suggestions: Inspect NBIO-31 3BSE011337R1 quarterly for loose connections, dust accumulation, and LED status (power: green, communication: flashing yellow, fault: red). Clean the module’s ventilation slots with compressed air to prevent overheating. Test input channels annually by applying a 24 V DC signal and verifying detection in the controller software; test output channels by activating them and measuring voltage at the terminals (should be 22 V to 26 V under load). If a channel fails, check for wiring issues or field device faults before replacing the module—use only ABB-certified replacements to maintain compatibility. Backup configuration data regularly using Automation Builder to facilitate quick recovery in case of module failure.

Service and guarantee commitment

NBIO-31 3BSE011337R1 is backed by a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB’s technical support team provides response within 4 hours for critical issues, with remote diagnostics available 24/7 to minimize downtime in industrial control systems. On-site service is available within 72 hours in major industrial regions for complex troubleshooting or replacement.

The warranty includes access to configuration software updates, technical documentation, and firmware upgrades. Extended service contracts offer annual performance verification and priority support, ensuring the module maintains reliable operation throughout its 15-year design lifespan. ABB’s commitment to quality underscores confidence in NBIO-31 3BSE011337R1 as a durable and trustworthy component in industrial automation systems.