Description

MEMORYCA: Product Overview

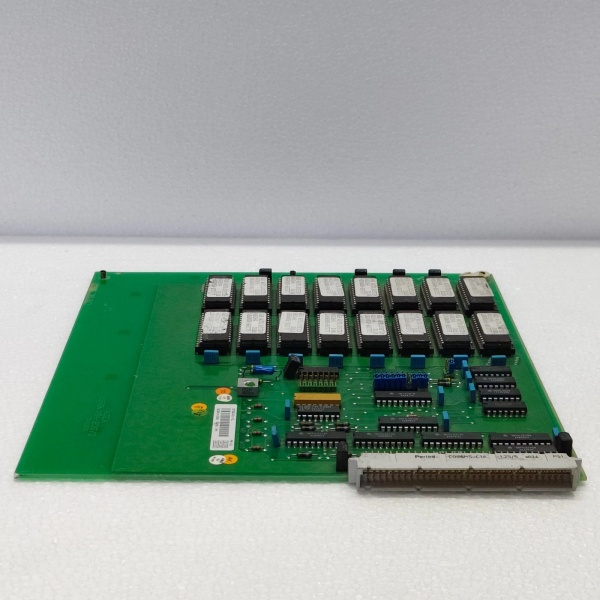

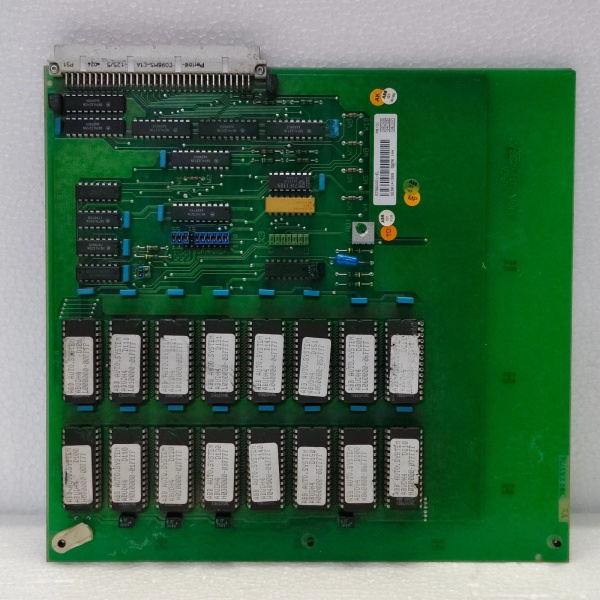

The MEMORYCA serves as a critical non-volatile memory expansion solution for ABB industrial automation systems, primarily integrated with MasterBus 300 and Advant Controller platforms to provide extended storage capacity for control programs, configuration parameters, and process data. Positioned as a supplementary memory layer between the main controller CPU and system backplane, it acts as a reliable data repository that preserves critical information even during complete power loss, ensuring system integrity and rapid recovery after outages.

Its core functionality revolves around providing 256 KB of battery-backed RAM (BBRAM) storage, which maintains data retention for up to 10 years without power. The board processes read/write requests from the controller CPU, storing everything from ladder logic programs and function block diagrams to calibration constants and historical process trends. It communicates with the main controller via the MasterBus 300 backplane, operating at bus speeds of up to 1 Mbps for efficient data transfer.

As part of ABB’s legacy automation ecosystem, the MEMORYCA inherits the platform’s reputation for rugged reliability and long-term operational stability. This module is specifically designed for mature industrial facilities operating Master Series controllers, offering a cost-effective memory upgrade path that extends the operational lifespan of existing automation infrastructure without requiring complete system replacement. Its plug-in design allows for straightforward installation in standard controller chassis slots, minimizing downtime during upgrades.

ABB MEMORYCA

MEMORYCA: Technical Specifications

- Model Number: MEMORYCA (Alternative P/N: 57160001-XXX)

- Manufacturer: ABB Industrial Automation Division

- Compatible System: ABB MasterBus 300, Advant Controller 31, Master Series 200/300

- Product Type: Battery-Backed RAM Memory Expansion Board

- Storage Capacity: 256 KB non-volatile battery-backed RAM

- Data Retention: 10 years minimum (with new lithium battery)

- Memory Type: Static RAM (SRAM) with lithium battery backup

- Bus Interface: MasterBus 300 (1 Mbps data transfer rate)

- Power Supply: 5 VDC (from controller backplane), 3.6 V lithium backup battery (replaceable)

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Protection Class: IP20 (chassis mounting)

- Mounting Type: Standard ABB controller chassis slot (3U height)

- Weight: 0.45 kg (0.99 lbs)

- Diagnostic Features: Battery status monitoring, memory integrity check, write-protect switch

- Data Storage Capabilities: Control programs, configuration data, process variables, alarm logs, trend data, calibration constants

- Dimensions: 160 mm × 100 mm × 25 mm (6.3″ × 3.9″ × 1.0″)

- Write Protection: Physical switch for data security

- Battery Type: CR2032 lithium coin cell (user-replaceable)

- Backplane Current Consumption: 15 mA at 5 VDC

Core Features & Customer Value

Battery-Backed Non-Volatile Storage: The MEMORYCA’s 256 KB battery-backed RAM provides guaranteed data retention for up to 10 years without power, protecting critical control programs and configuration data from loss during unexpected outages. For industrial facilities operating continuous processes (e.g., chemical plants, oil refineries), this feature eliminates the need for time-consuming system reconfiguration and program reloading after power failures, reducing downtime and ensuring product quality consistency.

Seamless Legacy System Integration: Designed specifically for ABB MasterBus 300 and Advant Controller platforms, the MEMORYCA offers plug-and-play compatibility with existing hardware, requiring no system firmware modifications or custom integration work. This compatibility is invaluable for facilities with mature automation infrastructure, as it allows memory capacity upgrades without replacing entire control systems, extending equipment lifespan by 5-10 years while deferring capital expenditures for full system modernization.

Data Integrity & Security: The MEMORYCA includes a physical write-protect switch that prevents accidental or unauthorized modification of stored programs and configuration data. This feature provides an additional layer of security in safety-critical applications, where unintended changes to control logic could result in hazardous conditions or regulatory non-compliance. Maintenance teams benefit from the ability to lock critical system data during troubleshooting or operator shifts, reducing the risk of human error-induced downtime.

Cost-Effective Memory Expansion: At a fraction of the cost of full controller replacement, the MEMORYCA provides a practical solution for facilities needing additional memory to support expanded control functionality, increased I/O points, or enhanced data logging capabilities. The module’s 256 KB capacity supports up to 10,000 data points or 500 program segments, making it suitable for both small process skids and large distributed control applications. For system integrators, this translates to reduced project costs and faster implementation times compared to full system upgrades.

ABB MEMORYCA

Typical Applications

The MEMORYCA is ideally suited for memory expansion in legacy ABB automation systems across multiple process industries where reliable data retention and system continuity are critical. In petrochemical refineries, it is widely used in distillation column control systems, storing complex control algorithms for temperature, pressure, and flow regulation, along with historical process data that enables quality traceability and troubleshooting of production issues. The battery-backed memory ensures that critical control parameters remain intact during power grid fluctuations common in these facilities, preventing costly process upsets and product off-specification batches.

In water and wastewater treatment plants, the MEMORYCA supports extended data logging of treatment process parameters, including pH levels, turbidity measurements, and chemical dosing rates. This historical data is essential for regulatory compliance reporting and process optimization initiatives aimed at reducing chemical usage and energy consumption. The module’s non-volatile storage capabilities ensure that treatment process configurations remain unchanged during power outages, preventing release of untreated water that could result in environmental violations and fines.

In power generation facilities, particularly those operating combined-cycle gas turbines, the MEMORYCA stores turbine startup/shutdown sequences, load ramp rates, and safety interlock parameters. These critical control programs must remain intact even during complete plant blackouts to ensure safe turbine operation and prevent catastrophic equipment damage. The module’s 10-year data retention capability provides long-term reliability for these safety-critical applications, reducing the risk of unplanned outages and ensuring compliance with NERC reliability standards.

In pharmaceutical manufacturing facilities, the MEMORYCA is used to store validated control programs for batch processing systems, ensuring that production recipes remain consistent across multiple batches. The write-protect feature prevents unauthorized modifications to these validated programs, maintaining compliance with FDA 21 CFR Part 11 regulations for electronic records and signatures. The module’s reliable data retention is essential for audit trails and product quality assurance, as it preserves critical process parameters that could impact drug efficacy and safety.