Description

ABB MB805 – Fieldbus Communication Module for AC 800M Controllers

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB MB805 |

| Manufacturer | ABB |

| Product Category | Fieldbus Communication Module |

| Compatibility | AC 800M Controller Family |

| Fieldbus Protocol | PROFIBUS DP-V1 |

| Data Transfer Rate | Up to 12 Mbps |

| Connection Ports | 1x PROFIBUS (9-pin D-sub) |

| Number of Devices | Up to 125 slaves |

| Isolation Voltage | 1500V AC |

| Power Supply | 5V DC (backplane powered) |

| Operating Temp | -25°C to +70°C |

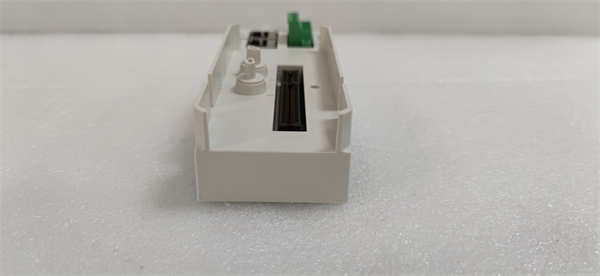

| Dimensions | 60 × 120 × 25 mm |

| Weight | 220g |

| Certifications | CE, UL, cUL, PROFIBUS Certified |

ABB MB805

Product Introduction

The ABB MB805 is a high-performance PROFIBUS DP communication module designed for ABB’s AC 800M process controllers. This industrial-grade fieldbus interface enables seamless integration of AC 800M systems with PROFIBUS DP networks, supporting both master and slave functionality.

As part of ABB’s automation ecosystem, the MB805 module provides reliable connectivity to field devices such as drives, I/O systems, and instrumentation. Its compact design and hot-swappable capability (when properly configured) ensure minimal downtime during maintenance or system upgrades.

The ABB MB805 stands out with its robust construction and advanced diagnostics, offering plant operators a dependable solution for industrial networking while maintaining compatibility with modern automation architectures. Its plug-and-play installation simplifies engineering efforts, reducing commissioning time for complex control systems.

Core Advantages and Technical Highlights

Reliable industrial communication:

The ABB MB805 delivers exceptional noise immunity with 1500V isolation between fieldbus and controller, ensuring stable data transmission in electrically noisy environments. The module supports PROFIBUS DP-V1 standard, including acyclic data communication for parameterization and diagnostics.

Enhanced system integration:

With support for up to 125 slave devices and data rates up to 12 Mbps, the MB805 enables efficient network architectures. The module supports all PROFIBUS DP protocol services, including MS0 (cyclic data exchange), MS1 (acyclic parameterization), and MS2 (diagnostic data).

Advanced diagnostics:

LED status indicators provide instant visual feedback for network status and activity. The module integrates seamlessly with ABB’s Automation Builder engineering environment, offering comprehensive diagnostic tools for network analysis and optimization.

Durability and maintenance:

Constructed with industrial-grade components, the ABB MB805 operates reliably across a wide temperature range (-25°C to +70°C). The module’s hot-swappable design (when properly implemented) allows for replacement without system shutdown.

Typical Application Scenarios

Process industries:

In chemical plants, the ABB MB805 connects AC 800M controllers to field instruments and motor starters via PROFIBUS DP. Refineries utilize its high-speed communication for real-time data exchange with process skids.

Manufacturing:

Automotive production lines use the module to network robots and transfer presses. The MB805‘s deterministic communication ensures synchronized operation across production cells.

Power generation:

The module serves as a communication gateway between turbine control systems and auxiliary equipment. Power plants leverage the MB805 to integrate intelligent field devices into their DCS networks.

Water infrastructure:

Municipal water treatment facilities employ the ABB MB805 to interface with remote I/O stations. Its robust design withstands humid environments while maintaining reliable PROFIBUS communication.

ABB MB805

Related Model Recommendations

ABB MB810: Modbus RTU communication module

ABB CI867: Ethernet/IP communication module

ABB CI871: PROFIBUS DP interface module with dual ports

ABB S800 I/O: Remote I/O system for field connectivity

ABB COM620: Cybersecurity gateway for network protection

ABB UAD148AE01: Base controller unit for system integration

ABB TP854: HMI panel for local monitoring and control

Installation, Commissioning and Maintenance

Installation preparation:

Before installing the ABB MB805, ensure the controller rack is powered off and properly grounded. Verify the operating environment meets specified temperature and humidity ranges. Prepare PROFIBUS-compliant cables and connectors, and ensure proper termination resistors are installed at network endpoints.

Maintenance suggestions:

Regularly inspect the MB805 for dust accumulation and clean using compressed air if necessary. Monitor LED indicators for abnormal status patterns. Perform annual network performance tests to verify signal integrity. When replacing the module, ensure GSD files are properly configured and follow proper electrostatic discharge (ESD) precautions.

Service and Guarantee Commitment

ABB stands behind the MB805 with a comprehensive 36-month warranty covering manufacturing defects. Our global support network provides 24/7 technical assistance, with on-site service available for critical applications. Customers benefit from firmware updates throughout the product lifecycle and access to ABB’s extensive knowledge base. The ABB MB805 is backed by our commitment to long-term spare parts availability, ensuring system longevity for industrial automation investments.