Description

Key Technical Specifications

- Model Number: INIIT13

- Manufacturer: ABB Bailey (Industrial Automation Division)

- System Compatibility: ABB Bailey INFI 90 DCS, Net 90 Systems, compatible with Bailey PCU (Process Control Units)

- Protocol Support: Modbus TCP (Master/Slave), Ethernet/IP (Adapter), ABB Cnet backplane protocol

- Communication Ports: 2 x 10/100Mbps Ethernet (RJ45), 1 x INFI 90 backplane connector

- Data Transfer Rate: Up to 100Mbps (Ethernet), 1Mbps (Cnet backplane)

- Operating Voltage: 24VDC ±10% (redundant inputs, 15W typical consumption)

- Isolation Rating: 2500VAC (Ethernet ports to backplane, power to signal)

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Dimensions (W×H×D): 178mm × 51mm × 330mm (standard INFI 90 rack mount)

- Weight: 0.9kg (1.98 lbs)

- Protection Features: ESD protection (±15kV human body model), overvoltage/undervoltage protection, short-circuit protection

- Status Indicators: Power (PWR), Ethernet Link (LINK1/LINK2), Communication Activity (ACT), Fault (FLT), Cnet Status (CNET)

ABB INIIT13

Field Application & Problem Solved

In the field, the biggest headache with legacy INFI 90 DCS is connecting it to modern digital systems—SCADA, MES, cloud platforms—without ripping and replacing the entire control infrastructure. At a coal-fired power plant in Indiana, a failed serial-to-Ethernet converter caused a 3-hour data outage, preventing operators from monitoring boiler pressure remotely. At a Louisiana refinery, incompatible protocols between the INFI 90 DCS and a new HMI led to manual data entry errors that cost $80k in rework.

The INIIT13 solves these integration nightmares by acting as a dedicated gateway between the INFI 90’s proprietary Cnet backplane and standard Ethernet networks. You’ll find this module in power plants (connecting DCS to grid management systems), refineries (linking process control to inventory tracking), and chemical facilities (integrating legacy batch control with modern quality management systems). It’s also a staple in brownfield upgrades, where replacing a decades-old DCS isn’t feasible but digital connectivity is mandatory.

Its core value lies in protocol translation and industrial ruggedness. Unlike generic Ethernet converters, it’s engineered to understand both the INFI 90’s Cnet protocol and standard Modbus TCP/Ethernet/IP—no custom programming required. The redundant 24VDC power inputs and 2500VAC isolation ensure it survives in harsh industrial environments where voltage spikes and noise are common. For operations teams, it’s the difference between a siloed legacy system and a connected, data-driven process—enabling real-time monitoring, remote diagnostics, and compliance reporting without downtime.

Installation & Maintenance Pitfalls (Expert Tips)

IP Address Conflict Bricks Communication

At a Texas chemical plant, a technician assigned the INIIT13 the same IP address as a SCADA server—causing a network collision that shut down data flow between the DCS and HMI. Always scan the network with a IP scanner before assigning an address to the INIIT13. Use a static IP outside the DHCP range, and document it in the plant’s network inventory. A 5-minute scan prevents 4 hours of troubleshooting.

Protocol Configuration Must Match Third-Party Devices

A rookie tech at an Ohio refinery configured the INIIT13 for Modbus TCP Slave while the SCADA system was set to Modbus TCP Master—resulting in “no response” errors. Use the INIIT13’s configuration software (via Ethernet port) to set the correct protocol mode: Modbus TCP Slave for SCADA polling, Modbus TCP Master for DCS-initiated data requests. Verify register maps and data types (16-bit integer, 32-bit float) match between the module and external devices—mismatches cause garbled data.

Ethernet Cable Shielding Prevents EMI Interference

Poorly shielded Ethernet cables at a Michigan power plant introduced noise that corrupted data packets, leading to intermittent “communication timeout” faults. Use shielded twisted-pair (STP) Cat5e or Cat6 cables for all Ethernet connections. Ground the shield at one end only (preferably at the switch side) to avoid ground loops. In high-noise environments (near motor control centers), route cables at least 30cm away from power cables.

Redundant Power Connection Is Mandatory

Skipping redundant power at a Pennsylvania steel mill caused the INIIT13 to fail during a power surge, cutting off DCS data to the safety system. Connect both 24VDC power inputs to separate power supplies (A/B bus) with common ground. The module automatically switches to the backup power source in <10ms—critical for 24/7 operations where data loss equals downtime.

Backplane Insertion Requires Proper Alignment

Forcing the INIIT13 into an INFI 90 rack at a California paper mill bent the backplane pins, taking down an entire control loop. The module’s backplane connector is keyed—align the key with the slot and apply even pressure until it seats fully. Never hammer or twist the module; if it doesn’t slide easily, check for debris or bent pins in the rack. Damaged backplane pins cost $3k+ to repair and require a shutdown.

Firmware Updates Fix Compatibility Bugs

At a Georgia refinery, an INIIT13 with outdated firmware (v2.1) failed to communicate with a new Ethernet/IP HMI. ABB releases firmware updates to fix protocol bugs and add compatibility with modern devices. Download the latest firmware from ABB’s support portal and install it via the module’s Ethernet port. Back up the configuration before updating—firmware flashes can erase custom settings.

ABB INIIT13

Technical Deep Dive & Overview

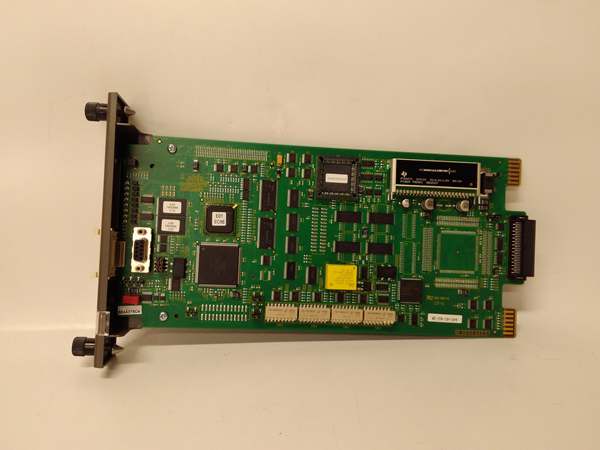

The ABB INIIT13 is a purpose-built Ethernet gateway module designed to bridge ABB Bailey’s legacy INFI 90 DCS with modern digital networks. At its core, it uses a 32-bit ARM processor (STM32F4) that handles protocol translation between the INFI 90’s proprietary Cnet backplane and Ethernet-based protocols (Modbus TCP/Ethernet/IP). This dedicated processor offloads communication tasks from the DCS’s PCU, preventing scan time overruns that degrade process control.

The module’s dual Ethernet ports support 10/100Mbps operation, with auto-negotiation to match the network switch’s speed. One port typically connects to the plant’s operational technology (OT) network (for SCADA/HMI), while the second can be used for maintenance or redundancy. The Cnet backplane interface communicates with the PCU at 1Mbps, retrieving process data (analog/digital I/O values, alarm status) and sending control commands from external systems.

Optical isolation (2500VAC) between the Ethernet ports, backplane, and power circuits protects the module from voltage transients and ground loops—common in industrial environments. Built-in diagnostics monitor Ethernet link status, Cnet communication, and power supply health, with LED indicators providing instant visual feedback. The module’s watchdog timer resets the processor if it locks up, ensuring maximum availability.

What sets the INIIT13 apart from generic converters is its seamless integration with the INFI 90 architecture. It’s recognized automatically by the PCU, which downloads configuration parameters (register maps, data rates) without manual intervention. The module’s firmware supports both big-endian and little-endian data formats, ensuring compatibility with most third-party devices.

In practice, the INIIT13 delivers reliable data transfer with <50ms latency—critical for real-time monitoring and control. At a Midwestern power plant, retrofitting 8 INIIT13 modules enabled the DCS to communicate with a cloud-based analytics platform, reducing unplanned downtime by 25% through predictive maintenance. In a Louisiana refinery, it eliminated manual data entry by linking the INFI 90 DCS to a modern MES, cutting rework costs by $150k annually.

The INIIT13’s industrial-hardened design—extended temperature range (-20°C to +60°C), vibration resistance (2g), and conformal-coated PCB—ensures it survives in the harshest plant environments. For field service teams, it’s a “set-it-and-forget-it” solution that solves the legacy DCS integration problem without compromising reliability.