Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB IMRIO02 |

| Manufacturer | ABB |

| Product Category | Remote I/O Interface Module |

| System Compatibility | Symphony® Plus DCS |

| Interface Type | Ethernet (RJ45) / Fiber Optic (optional) |

| Communication Protocols | Modbus TCP/IP, IEC 61850, OPC UA |

| Data Throughput | 100 Mbps (Full duplex) |

| Redundancy Support | Dual-redundant Ethernet rings |

| Operating Voltage | 24 V DC ±10% |

| Power Consumption | 8 W (typical) |

| Operating Temperature | -40°C to +70°C |

| Shock Resistance | 15 g (11 ms duration) |

| Vibration Immunity | 2 g (5-150 Hz) |

| Certifications | UL Class I Div 2, IEC 61850-3, CE, RoHS |

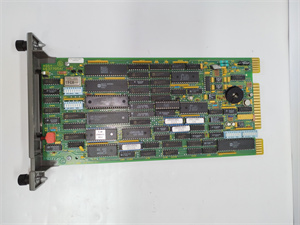

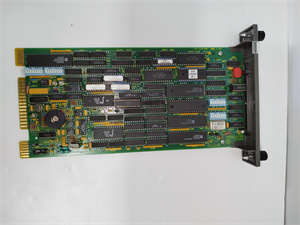

ABB IMRIO02

Product Introduction

The ABB IMRIO02 is a high-availability Remote I/O Interface Module engineered for ABB’s Symphony® Plus distributed control systems. Serving as a critical communication gateway, this module extends control capabilities to geographically dispersed field equipment by interfacing with remote I/O racks via rugged industrial Ethernet networks. The ABB IMRIO02 enables real-time data exchange between Symphony® Plus controllers and thousands of I/O points across multiple remote locations, effectively eliminating traditional wiring constraints.

Designed for mission-critical infrastructure, the module supports dual-redundant network topologies with sub-second failover, ensuring uninterrupted process control in power generation, water networks, and oil & gas facilities. Its integrated support for IEC 61850 simplifies integration with intelligent electrical devices (IEDs), while OPC UA compatibility enables secure data sharing with enterprise systems. The ABB IMRIO02 fundamentally transforms distributed control architectures by reducing cabling costs by up to 70% while enhancing system scalability and diagnostic visibility.

Core Advantages and Technical Highlights

Network Resilience: The ABB IMRIO02 implements PRP/HSR (Parallel Redundancy Protocol/High-availability Seamless Redundancy) for zero-packet-loss failover (< 5ms) during network disruptions. Dual power inputs with reverse-polarity protection further eliminate single points of failure.

Cybersecurity Architecture: Featuring hardware-trusted platform modules (TPM 2.0), the module enforces secure boot, encrypted communications (TLS 1.3), and role-based access control. Continuous integrity monitoring detects firmware tampering, critical for NERC-CIP compliance in energy systems.

Deterministic Performance: With 8 MB packet buffer memory and IEEE 1588v2 Precision Time Protocol (PTP) synchronization, the ABB IMRIO02 achieves ±1 μs clock accuracy across distributed I/O nodes, essential for sequence-of-event (SOE) recording.

Diagnostic Depth: Integrated web server provides real-time health analytics including network jitter/latency heatmaps, error frame counters, and temperature history. Predictive algorithms flag deteriorating components (e.g., fans, capacitors) 30+ days before failure.

Simplified Engineering: Auto-discovery of connected I/O racks in Control Builder engineering suite reduces configuration time by 80%. Module replacement requires no software reconfiguration – parameters auto-restore from controller.

Typical Application Scenarios

In thermal power plants, the ABB IMRIO02 integrates boiler burner management systems and turbine auxiliaries spread across 500m+ distances. Its -40°C rating allows deployment in coal conveyor galleries, while IEC 61850-3 certification ensures stability amid 10kV switchyard electromagnetic interference. Redundant rings maintain control during cable excavator damage events.

For municipal water SCADA systems, the module connects pump stations and reservoir level monitors across city-wide fiber networks. The ABB IMRIO02’s Modbus TCP/IP gateway functionality integrates legacy RTUs without protocol converters, while OPC UA publishes water quality data to cloud analytics platforms.

In offshore platforms, the module’s corrosion-resistant coating (ISO 12944 C5-M) withstands salt spray. Fiber-optic variants prevent lightning-induced surges between process modules, with HSR redundancy ensuring safety system integrity during network storms.

Related Model Recommendations

ABB IMRIO03: Enhanced version with PROFINET IRT support for motion control

ABB SAO01F: Fiber-optic media converter for extending IMRIO02 links beyond 10 km

ABB REF615: IEC 61850-compliant feeder relay directly interfacing with IMRIO02

ABB CI871: PROFINET controller module for Symphony® Plus main racks

ABB SD832: 16-channel analog input module for remote I/O stations

ABB NETA-21: Network analyzer for troubleshooting IMRIO02 Ethernet rings

ABB PP885: Controller pairing with IMRIO02 for turbine control applications

ABB TU847: Termination unit for remote I/O rack integration

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Verify DIN rail strength (≥ 75 N/mm²) and cabinet ambient temperature. Use shielded CAT6A cables (minimum bend radius 30mm) with drain wires grounded at one end. For fiber variants, inspect connectors for contamination using IEC 61300-3-35 inspection probes. Maintain 50mm clearance above module for heat dissipation.

Maintenance Suggestions: Quarterly inspect Ethernet port LEDs (green = link, amber = activity). Annually clean air vents with dry nitrogen. Monitor “Predictive Health Index” in Control Builder – values <80% trigger fan replacement. Replace units during planned outages using ABB’s hot-swap procedure: 1) Disable redundancy partner, 2) Wait for “Standby” LED, 3) Slide module out. Firmware updates require Symphony® Plus Engineering V3.3 or later.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the IMRIO02, covering component failures and performance deviations. Our “Mission Critical” support tier offers 4-hour response for power/water sector customers, including loaner module dispatch. Global lifecycle commitment guarantees spare availability until 2040.

Technical support includes free access to ABB’s Network Design Studio for topology validation and cyber-risk assessments. Extended service contracts cover firmware updates with regression testing for legacy system compatibility. All modules undergo 168-hour burn-in testing at 70°C with 100% network load simulation prior to shipment.