Description

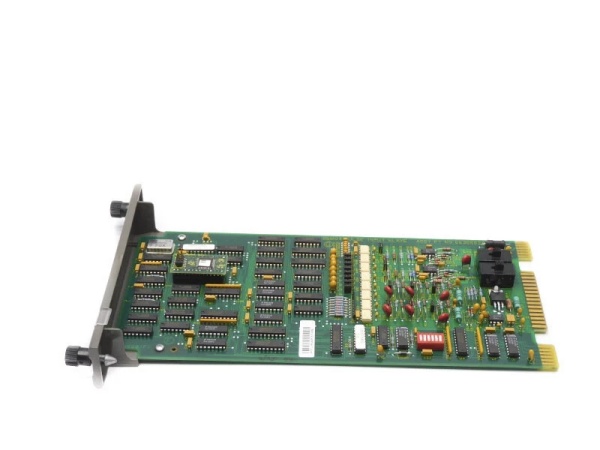

IMDSM04 – Product Overview

The IMDSM04 is a slave‑side pulse‑input module designed for ABB’s distributed automation architecture. It resides in the I/O tier of a control system, receiving raw pulse signals from sensors such as encoders, flow meters, or speed transducers and converting them into deterministic digital data for the host controller (PLC, DCS, or SIS). By handling signal conditioning, edge selection, and high‑speed counting locally, the module off‑loads the central processor and ensures reliable timing for critical control loops.

IMDSM04 belongs to ABB’s Symphony Pulse family, part of the Harmony Rack (HR) series. The family shares a common hardware platform, configuration tools, and diagnostic framework, allowing engineers to reuse device descriptions and maintenance procedures across multiple installations. Its modular DIN‑rail form factor enables straightforward integration into existing ABB racks or panels, while the RS‑485 interface (Modbus RTU) provides seamless network connectivity.

IMDSM04 – Technical Specifications

- Model Number: IMDSM04

- Manufacturer: ABB

- Product Type: Pulse Input Slave Module (4 independent channels)

- Power Supply: 24 V DC, 80 mA typical consumption

- Operating Temperature: –20 °C to +60 °C

- Environmental Rating: IP20, DIN‑rail mountable

- Communication Interface: RS‑485 (Modbus RTU), optional RS‑232

- Input Voltage Range (per channel): 4 – 6 V DC or 21.6 – 27 V DC (isolated)

- Edge Detection: Configurable rising, falling, or dual‑edge per channel

- Resolution: 16‑bit counting, frequency measurement up to 50 kHz

- Response Time: Selectable 20 µs – 655 ms per channel

- Channel Modes: Cumulative count, frequency, or period measurement

- Isolation Voltage: 2500 V AC per channel

- Dimensions: Length 71.12 mm, Width 271.78 mm, Height 358.14 mm

- Weight: Approx. 0.3 kg

- Certifications: CE, UL, CE‑Mark compliance

IMDSM04

Core Features & Customer Value

High‑Precision Pulse Processing – Each of the four channels offers 16‑bit resolution and up to 50 kHz frequency measurement. Engineers gain accurate speed, flow, or position data without external scaling hardware, which simplifies system design and improves loop stability.

Flexible Edge Configuration – The ability to select rising, falling, or dual‑edge detection per channel lets users adapt the module to a wide variety of sensor types, reducing the need for additional signal conditioning equipment.

Local Counting & Diagnostics – By performing counting and frequency calculations on‑board, the module reduces network traffic and CPU load on the host controller. Built‑in diagnostics (e.g., over‑voltage, isolation fault) provide early warning of sensor or wiring issues, helping to avoid unexpected shutdowns.

Robust Industrial Design – IP20 protection, 2500 V AC isolation, and a temperature range of –20 °C to +60 °C ensure reliable operation in harsh environments such as steel mills, cement plants, and marine applications. The compact DIN‑rail package saves valuable rack space and supports quick field replacement.

Standardized Communication – RS‑485 with Modbus RTU aligns with existing ABB and third‑party networks, enabling seamless integration into PLC, DCS, or SIS architectures. The common protocol also simplifies commissioning and maintenance through familiar tools.

IMDSM04

Typical Applications

- Turbine Speed Monitoring – In combined‑cycle power plants, the IMDSM04 captures high‑frequency pulses from turbine shaft encoders, delivering precise RPM data to the plant’s DCS for governor control and performance tracking.

- Conveyor Belt Count & Speed – Packaging facilities use the module to count items passing optical sensors and to measure belt speed, allowing real‑time throughput optimization without additional PLC logic.

- Flow Meter Pulse Integration – Water‑treatment and petrochemical plants connect pulse‑output flow meters to the IMDSM04, leveraging its frequency mode to convert pulses into volumetric flow rates directly within the control system.

- Rotary Encoder Interface for Robotics – Manufacturing cells employ the module to read encoder pulses from robotic joints, providing high‑resolution position feedback for motion control loops.

- Safety‑Instrumented System (SIS) Redundancy – In safety‑critical shutdown circuits, the module’s isolated inputs and deterministic counting support SIL‑2 compliant monitoring of emergency stop button activations and valve position feedback.