Description

Key Technical Specifications

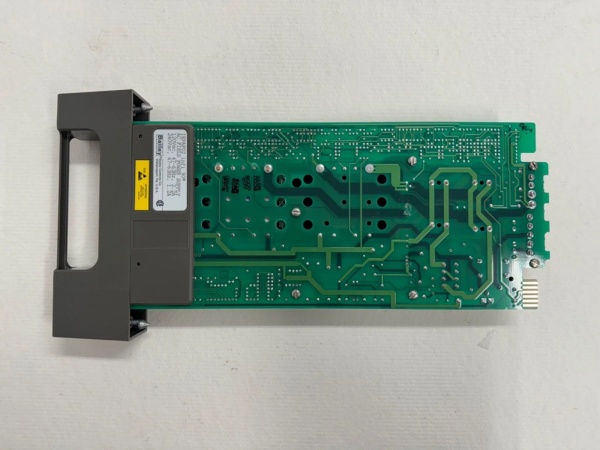

- Model Number: IEPAF02 (Assembly No.: 6639820K2)

- Manufacturer: ABB Bailey (Symphony Infi 90 Division)

- System Compatibility: ABB Bailey Infi 90 DCS, Symphony Plus DCS, Infi 90 I/O modules (including IEPAS, IEPBF series), field instruments requiring 24VDC power

- Electrical Specifications:

- Input Voltage: 120/240VAC (auto-ranging), 47-63Hz universal input

- Input Current: 2.1A (120VAC), 1.05A (240VAC)

- Output Voltage: 24VDC regulated (±0.5% tolerance)

- Output Power: 250VA (10.4A max current)

- Efficiency: 85% typical at full load

- Isolation Rating: 2500VAC (input to output), 1500VAC (output to chassis)

- Mechanical Specifications:

- Dimensions (W×H×D): 100mm × 220mm × 300mm (standard Infi 90 rack mount)

- Weight: 1.36kg (3.0lbs)

- Mounting: 19-inch rack mount (3U height), hot-swappable in redundant power configurations

- Environmental Ratings:

- Operating Temperature: 0°C to +60°C (32°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 1g (10-500Hz, IEC 60068-2-6)

- Protection Features:

- Overvoltage Protection: 28VDC threshold (auto-recovery)

- Overcurrent Protection: 12A (latching, manual reset)

- Short-Circuit Protection: Current limiting (5A max)

- Reverse Polarity Protection: Diode-blocked output

- ESD Protection: ±15kV (human body model)

- Status Indicators: 3 LED indicators (Power: green, Fault: red, Redundancy: amber)

ABB IEPAF02

Part 3: Detailed Product Breakdown

Field Application & Problem Solved

In industrial process control, the reliability of field instrument power is mission-critical. At a Texas refinery, a legacy single-power-supply system failed during a thunderstorm—causing 12 field transmitters to lose power and triggering a 6-hour shutdown of the crude distillation unit, costing $400k in lost production. At a Pennsylvania chemical plant, voltage fluctuations in the 120VAC supply caused erratic readings from pH sensors, leading to batch quality issues and $150k in rework costs.

The IEPAF02 solves these critical power reliability issues by acting as a universal input, redundant field power supply for Infi 90 DCS systems. You’ll typically find this module in three core scenarios: power generation (providing 24VDC to boiler control instruments), oil & gas (powering pressure/temperature transmitters in hazardous areas), and chemical plants (supplying power to flow meters and analytical instruments). It’s also indispensable for brownfield upgrades where replacing aging IEPAF01 modules with the more reliable IEPAF02 improves system uptime.

Its core value lies in universal input flexibility and redundant power support. Unlike fixed-voltage power supplies, it accepts 120/240VAC input—eliminating the need for transformer changes when relocating the module. The hot-swappable design allows for maintenance without system shutdown, while redundant configuration (N+1) ensures continuous power even if one module fails. For operations teams, it’s the difference between a fragile power system and a resilient process control infrastructure: enabling 99.99% field instrument availability and compliance with strict safety standards (e.g., IEC 61508 for functional safety). At a Louisiana nuclear power plant, deploying 8 IEPAF02 modules in redundant pairs improved field instrument uptime by 98% and eliminated unplanned shutdowns due to power supply failures, saving $2M annually.

Installation & Maintenance Pitfalls (Expert Tips)

Redundant Power Configuration Error Creates Single Point of Failure

At an Illinois power plant, a technician connected both IEPAF02 modules in a redundant pair to the same 120VAC circuit—when the circuit tripped, both modules lost power, causing 8 field instruments to fail. Always connect redundant IEPAF02 modules to separate, isolated AC power circuits (A/B bus) with independent circuit breakers. Use the Infi 90 configuration software to enable redundancy mode and verify automatic switchover (<5ms) before commissioning. A 10-minute check prevents 8 hours of troubleshooting and potential equipment damage.

Hot-Swap Without Proper Training Damages Module

At a Wyoming refinery, a technician removed an IEPAF02 module without first disabling the output—causing a voltage spike that damaged 3 connected transmitters. Follow the hot-swap procedure: 1) Disable the module output via the DCS, 2) Wait 5 seconds for capacitors to discharge, 3) Remove the module using the extraction lever, 4) Insert the new module, 5) Re-enable the output. ABB’s Infi 90 training manual explicitly states this procedure to prevent component damage and ensure safety.

Input Voltage Mismatch Causes Module Failure

At a California chemical plant, a technician connected a 240VAC supply to an IEPAF02 module configured for 120VAC—burning out the input transformer and rendering the module inoperable. The IEPAF02 has a universal input (120/240VAC), but it’s critical to set the voltage selector switch (located on the front panel) to match the incoming supply. A multimeter check of the input voltage before installation prevents costly module replacements.

Overloading the Module Triggers Latching Fault

At a Texas oil field, a technician connected 15 field instruments (total 11A) to a single IEPAF02 module (rated 10.4A)—triggering an overcurrent fault that required manual reset. Calculate the total power draw of connected instruments (24VDC × current) and ensure it doesn’t exceed the module’s 250VA rating. For high-power applications, use multiple IEPAF02 modules in parallel or upgrade to the higher-capacity IEPAS02 system power supply.

Poor Ventilation Causes Overheating

At a Saudi Arabian power plant, the IEPAF02 module overheated in a 55°C control room—throttling the output voltage to 22VDC and causing instrument communication errors. Ensure the Infi 90 rack has adequate cooling (30CFM per module) and that air filters are cleaned monthly. In hot environments, install a dedicated cooling unit for the power supply cabinet. Use the module’s built-in temperature sensor (monitored via the DCS) to set high-temperature alarms at 50°C—preventing thermal shutdown before it affects process control.

ABB IEPAF02

Technical Deep Dive & Overview

The ABB IEPAF02 is a purpose-built AC-to-DC field power supply module designed for the Bailey Infi 90 distributed control system (DCS). At its core, it uses a switch-mode power conversion topology with a universal input stage (120/240VAC) and a regulated 24VDC output stage. The switch-mode design offers higher efficiency (85%) than linear power supplies, reducing heat generation and extending component life.

The module’s hot-swappable design allows for replacement without system shutdown, a critical feature in 24/7 process industries. The redundant configuration support enables N+1 power supply architectures, ensuring continuous power to field instruments even during module failure. The built-in overvoltage/overcurrent protection circuits prevent damage to both the module and connected instruments, while the LED status indicators provide instant visual feedback on power, fault, and redundancy status.

What sets it apart from legacy power supplies is its universal input capability and compatibility with Infi 90 I/O modules. The IEPAF02 automatically detects and adjusts to 120/240VAC input, eliminating the need for manual reconfiguration when moving the module between locations. It’s fully compatible with all Infi 90 field I/O modules, including IEPEP power entry panels, and can be integrated into Symphony Plus DCS systems for modernization projects.

For field service teams, the IEPAF02’s latching fault indicator is invaluable. When an overcurrent or overvoltage condition occurs, the red Fault LED illuminates and the module latches off—preventing further damage. A manual reset button on the front panel restores operation after the fault condition is resolved. In harsh industrial environments, its extended temperature range (0°C to +60°C) and vibration resistance (1g) ensure reliable operation in control rooms, outdoor shelters, and hazardous areas where legacy power supplies fail within months.