Description

Key Technical Specifications

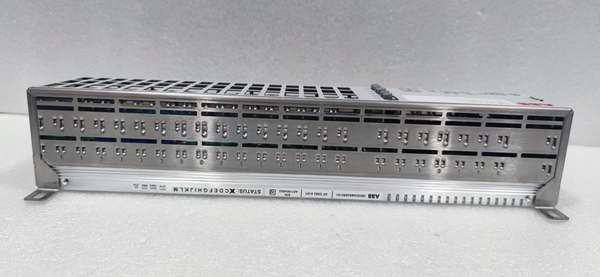

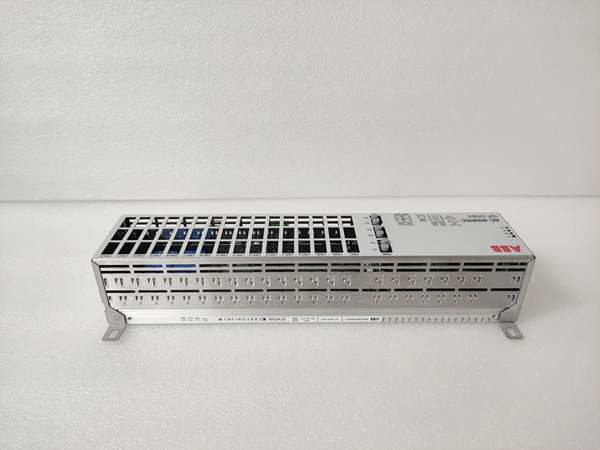

- Model Number: GFD563A101 3BHE046836R0101

- Manufacturer: ABB Power Generation Division

- System Compatibility: ABB AC 800PEC Excitation Control System, compatible with Symphony Harmony DCS, AC 800M controllers

- Processor: Dual-core ARM Cortex-A9 (800MHz), separate high-speed (100µs) and low-speed (1ms) control cores

- Memory: 1GB DDR3 RAM, 8GB eMMC flash (for firmware, configuration, and data logging)

- Communication Interfaces:

- 2 x 10/100/1000BASE-T Ethernet (TCP/IP, Modbus TCP, IEC 61850-8-1)

- 1 x PROFIBUS DP-V1 (master/slave, up to 12Mbps)

- 1 x Fiber Optic I/O Link (100Mbps, for connecting to AC 800PEC I/O modules)

- 1 x RS-232 (service port, 115200 bps)

- Control Cycle: 100µs (high-speed core for current regulation), 1ms (low-speed core for voltage regulation and communication)

- Operating Voltage: 24VDC ±10% (redundant inputs, 25W typical consumption)

- Isolation Rating: 2500VAC (communication ports to backplane), 5000VAC (power to signal)

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Dimensions (W×H×D): 220mm × 100mm × 300mm (standard AC 800PEC rack mount)

- Weight: 1.2kg (2.65 lbs)

- Protection Features: ESD protection (±15kV human body model), overvoltage/undervoltage protection, short-circuit protection, watchdog timer (10ms timeout)

ABB GFD563A101 3BHE046836R0101

Part 3: Detailed Product Breakdown

Field Application & Problem Solved

In power generation, the biggest challenge is maintaining grid stability during load transients and faults. At a coal-fired power plant in Pennsylvania, a legacy analog excitation system failed to respond to a 20% load step change within 100ms—causing voltage fluctuations that tripped a nearby industrial customer. At a Texas wind farm, a conventional PLC-based excitation controller with 5ms cycle time couldn’t handle the rapid voltage changes from variable wind speeds, leading to grid code violations and $120k in penalties annually.

The GFD563A101 3BHE046836R0101 solves these critical grid compliance issues by acting as a high-speed excitation control processor with dual-core architecture. You’ll typically find this module in three core scenarios: power generation (synchronous generator excitation control for thermal, hydro, and wind plants), heavy industry (large motor excitation for steel mill rolling mills, cement kilns), and grid support (STATCOM and SVC applications for reactive power compensation). It’s also indispensable for brownfield upgrades where replacing the entire excitation system is impractical but control performance must meet modern grid codes (e.g., FERC Order 666, NERC PRC-024).

Its core value lies in unmatched control responsiveness and grid-compliant performance. Unlike legacy excitation controllers, it delivers a 100µs control cycle for current regulation—fast enough to counteract sub-cycle grid faults. The dual-core design separates high-speed control (current loop) from low-speed tasks (communication, data logging), preventing control delays. For operations teams, it’s the difference between a non-compliant system and a grid-friendly asset: enabling ride-through capability during voltage sags, precise reactive power control, and compliance with strict grid codes. At a Florida nuclear power plant, deploying 4 GFD563A101 modules improved voltage regulation by 90% and eliminated grid code violations, saving $300k annually in potential penalties.

Installation & Maintenance Pitfalls (Expert Tips)

Synchronization Signal Mismatch Causes Unstable Operation

At an Illinois power plant, a technician connected the GFD563A101 to a 50Hz sync signal while the generator operated at 60Hz—resulting in erratic voltage regulation and a 3-hour shutdown. Always verify sync signal frequency (50/60Hz), phase sequence, and voltage level (100V/220V) match the generator. Use the AC 800PEC configuration software to set sync parameters and test with a phase rotation meter before commissioning. A 10-minute check prevents 8 hours of troubleshooting and potential equipment damage.

Fiber Optic I/O Link Misalignment Kills Communication

At a Wyoming wind farm, unpolished fiber optic connectors caused 15% data loss between the GFD563A101 and I/O modules—triggering false “I/O fault” alarms and unnecessary generator trips. Use APC (angled physical contact) connectors with single-mode fiber (9/125µm) for the I/O link. Clean connectors with lint-free wipes and isopropyl alcohol before installation. In high-vibration environments (turbine nacelles), use armored fiber cables and strain relief to prevent connector damage.

Redundant Power Supply Configuration Error Risks Single Point of Failure

A rookie tech at a California hydro plant connected both redundant power inputs of the GFD563A101 to the same 24VDC bus—when the bus failed, the module shut down, causing a generator outage. Connect each power input to separate, isolated 24VDC power supplies (A/B bus) with common ground. The module automatically switches to the backup supply in <10ms—critical for 24/7 operations where even a 1-second outage equals lost generation.

ABB GFD563A101 3BHE046836R0101

Firmware Version Incompatibility Breaks DCS Integration

At a Texas refinery, the GFD563A101 with firmware v2.3 failed to communicate with the Symphony DCS running v5.1—resulting in lost telemetry and manual operation of the generator. ABB releases firmware updates to fix IEC 61850 and Modbus TCP compatibility issues. Download the latest firmware from ABB’s support portal and install it via the service port using a USB flash drive. Back up the configuration first—firmware flashes erase custom settings, and a corrupted configuration can render the module inoperable.

Heat Dissipation Issues Degrade Processor Performance

At a Saudi Arabian power plant, the GFD563A101 overheated in a 55°C control room—throttling the processor to 50% speed and increasing control cycle time to 200µs. Ensure the AC 800PEC rack has adequate cooling (40CFM per module) and that air filters are cleaned monthly. In hot environments, install a dedicated cooling unit for the excitation control cabinet. Use the module’s built-in temperature sensor (monitored via the DCS) to set high-temperature alarms at 50°C—preventing thermal throttling before it affects control performance.

Reactive Power Setpoint Configuration Error Violates Grid Codes

At a New York power plant, a technician set the GFD563A101 to maintain constant power factor (0.9 lagging) instead of constant voltage—resulting in reactive power overproduction and a $50k grid code violation. Always configure the module for constant voltage mode (default for generators) unless grid codes require otherwise. Use the AC 800PEC HMI to monitor reactive power output and set alarm thresholds at ±10% of the utility’s specified range. A 5-minute review of grid code requirements prevents costly violations and ensures grid compliance.

Technical Deep Dive & Overview

The ABB GFD563A101 3BHE046836R0101 is a purpose-built dual-core excitation control processor designed for ABB’s AC 800PEC high-performance excitation system. At its core, it uses a 32-bit dual-core ARM Cortex-A9 processor (800MHz) that manages two critical functions: high-speed current regulation (100µs cycle) and low-speed tasks (communication, data logging, and voltage regulation at 1ms cycle). This architecture eliminates the need for separate controllers, reducing complexity and improving reliability.

The module’s fiber optic I/O link communicates with AC 800PEC I/O modules at 100Mbps, transmitting control signals (PWM commands for rectifiers) and receiving feedback (generator voltage, current, rotor position). The Ethernet ports support IEC 61850-8-1 (for DCS integration) and Modbus TCP (for remote monitoring), while the PROFIBUS DP-V1 interface connects to auxiliary equipment (cooling systems, voltage regulators).

What sets it apart from legacy excitation controllers is its grid-compliant control algorithms. The GFD563A101 implements ABB’s proprietary “Fast Response Excitation Control” (FREC) algorithm, which provides:

- Sub-cycle current regulation (100µs) for fault ride-through capability

- Adaptive voltage control to maintain terminal voltage within ±0.5% of setpoint

- Reactive power sharing between multiple generators (droop control)

- Grid code-compliant response to voltage sags/swells (IEC 61968, IEEE 1212)

For field service teams, the GFD563A101’s LED diagnostics are invaluable. A steady PWR LED confirms redundant power, blinking CPU LEDs indicate core activity, a solid COM LED signals communication with I/O modules, a flashing FLT LED means a recoverable fault, and a lit SYNC LED indicates valid generator synchronization. In harsh industrial environments, its extended temperature range (-20°C to +60°C) and vibration resistance (2g) ensure reliable operation in turbine halls, switchyards, and outdoor installations where legacy controllers fail within months.

In practice, the GFD563A101 delivers <0.1% voltage regulation error and <100µs response time to grid faults—performance that legacy systems can’t match. At a Texas wind farm, retrofitting 12 GFD563A101 modules enabled the plant to meet FERC Order 827 requirements for low-voltage ride-through, unlocking access to $2M in annual grid support payments. For field service engineers, it’s a “set-it-and-forget-it” solution that solves legacy excitation control problems without compromising reliability or grid compliance.