Description

Detailed parameter table

| Parameter name | Parameter value |

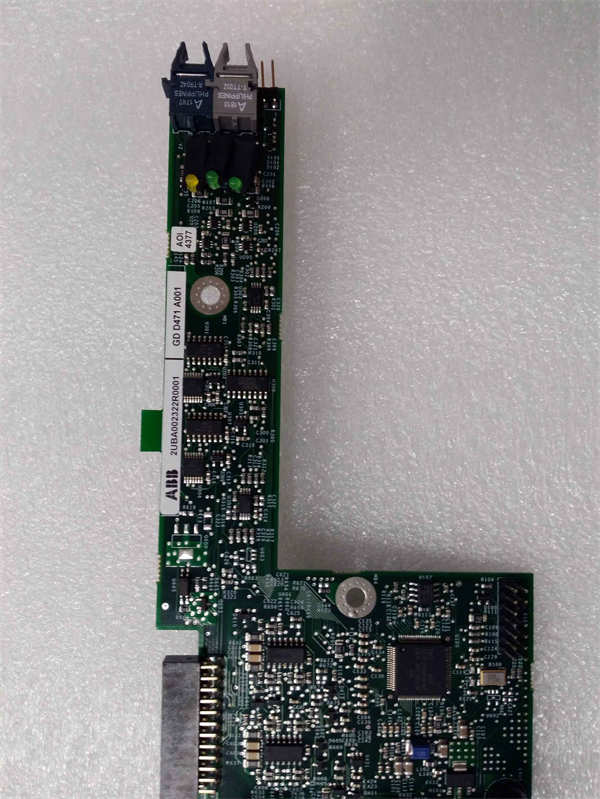

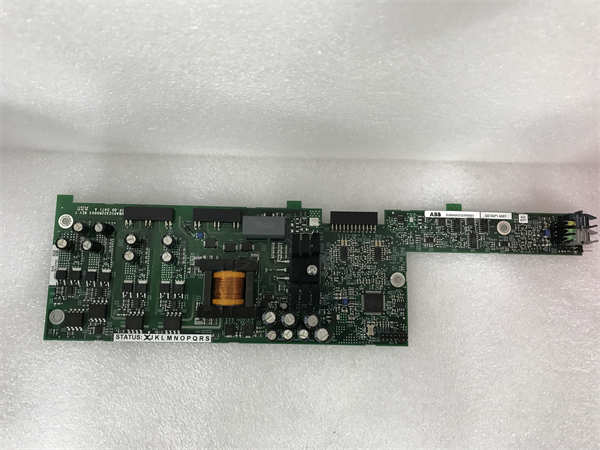

| Product model | GDD471A001 |

| Manufacturer | ABB |

| Product category | Digital output module (for industrial control systems) |

| Number of channels | 16 digital outputs |

| Output voltage | 24 V DC |

| Maximum output current | 2 A per channel (5 A total per module) |

| Response time | ≤1 ms (turn on/off) |

| Isolation rating | 2.5 kV AC (channel to backplane) |

| Communication protocol | PROFINET |

| Operating temperature | -25°C to 70°C |

| Protection rating | IP20 |

| Mounting type | DIN rail (35mm) |

| Dimensions | 105mm × 165mm × 45mm |

| Certifications | IEC 61131-2, CE, UL, ATEX |

ABB GDD471A001

Product introduction

The GDD471A001 is a high-performance digital output module from ABB, engineered to serve as a reliable interface between industrial control systems and field actuators. As a key component in ABB’s distributed control architecture, this module converts digital control signals from PLCs or DCS systems into electrical outputs, enabling precise control of devices such as solenoid valves, motor starters, and indicator lights in automated processes.

What distinguishes the GDD471A001 is its 16-channel design with robust current handling capabilities—each channel can deliver up to 2 A, making it suitable for both small actuators and mid-sized loads like conveyor motors. Its integration with PROFINET ensures seamless communication with ABB’s AC 800M controllers and third-party systems, allowing for real-time monitoring and remote configuration. Whether deployed in automotive plants, food processing facilities, or water treatment plants, the GDD471A001 provides consistent performance, ensuring reliable operation of critical control loops.

Core advantages and technical highlights

High current handling with overload protection: The GDD471A001 supports 2 A per channel (with a 5 A total module limit), enabling direct control of mid-sized actuators without external relays. Each channel features built-in overload protection that shuts down the output if current exceeds 2.5 A, preventing damage to the module and connected devices. This is particularly valuable in applications like packaging lines, where sudden jam conditions can cause solenoid valves to draw excess current.

Fast response for time-critical applications: With a response time of ≤1 ms for both turn-on and turn-off operations, the GDD471A001 ensures precise timing in high-speed processes. In automotive assembly, for example, it can synchronize the activation of welding clamps with robot movements, ensuring parts are held securely during welding cycles. This speed also minimizes wear on mechanical components by reducing actuation delays.

PROFINET integration with diagnostic capabilities: The GDD471A001 leverages PROFINET for high-speed communication, enabling real-time status updates and remote diagnostics. Through the protocol, users can monitor channel-specific current draw, overload events, and connection status via the control system HMI. In a chemical plant, this allows operators to quickly identify a faulty valve by detecting a drop in current on its associated channel, reducing troubleshooting time.

Robust environmental resilience: Designed to operate in -25°C to 70°C, the GDD471A001 thrives in extreme industrial environments—from freezing cold storage facilities to hot foundries. Its 2.5 kV AC isolation protects sensitive control systems from voltage transients, while ATEX certification allows deployment in Zone 2 hazardous areas, such as paint booths or chemical mixing rooms, without additional enclosures.

Typical application scenarios

In automotive paint shops, the GDD471A001 controls the solenoid valves that regulate paint flow and robotic arm movements. Each channel activates a specific valve or motor, with PROFINET enabling the PLC to adjust timings based on real-time sensor data. The module’s fast response ensures precise paint application, while overload protection prevents damage if a valve becomes clogged. Its wide temperature tolerance allows reliable operation in the heated curing zones of the paint line.

In water treatment plants, the GDD471A001 manages the opening and closing of isolation valves and pump starters across filtration and disinfection stages. By delivering 2 A per channel, it directly controls the valve actuators without external relays, simplifying cabinet design. PROFINET connectivity allows the central SCADA system to monitor valve status, and in case of a stuck valve (detected via sustained high current), the module triggers an alert, enabling proactive maintenance.

ABB GDD471A001

Related model recommendations

GDD472A001: An 8-channel variant of the GDD471A001 with 5 A per channel, ideal for larger loads like industrial pumps.

BDD110 HNLP205879R1: A digital input module that pairs with the GDD471A001 to create complete input-output control loops.

CI854A 3BSE022469R1: A PROFINET interface module that extends the GDD471A001’s communication range in large-scale systems.

AC 800M 3BSE013236R1: A controller optimized to work with the GDD471A001 for advanced process control applications.

TB857 3BSE013269R1: A surge protection terminal block that safeguards the GDD471A001’s outputs in high-EMI environments.

DOP110 3BSE008550R1: A relay output module that complements the GDD471A001 for applications requiring AC voltage outputs.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the GDD471A001, ensure the DIN rail is securely mounted in a control cabinet with ambient temperature between -25°C and 70°C. Verify the power supply provides 24 V DC with a minimum 5 A capacity to support peak loads. Use 0.75-1.5 mm² cables for field connections, with proper fusing (3 A per channel) for high-current devices. Required tools include a torque screwdriver (0.5-0.7 Nm), wire strippers, and a multimeter. Avoid mounting near high-voltage cables or heat sources exceeding 70°C.

Maintenance suggestions: Inspect the GDD471A001 quarterly for loose terminal screws and dust buildup, cleaning with compressed air if needed. Test each channel monthly by activating it via the control system and measuring output voltage (should be 24 V DC ±5%). Monitor PROFINET diagnostics for overload events, which indicate potential issues with connected devices. If a channel fails, isolate the problem by testing with a known-good actuator; if the fault persists, replace the module with an ABB-certified spare. Calibrate response time annually using an oscilloscope to ensure it remains ≤1 ms.

Service and guarantee commitment

The GDD471A001 comes with a 5-year warranty from the installation date, covering manufacturing defects and ensuring compliance with published specifications. ABB guarantees replacement of faulty units within 48 hours for critical applications, minimizing production downtime. Technical support is available 24/7 via ABB’s global network of automation specialists, offering assistance with configuration, troubleshooting, and integration. Extended service contracts include annual preventive maintenance, firmware updates, and priority support, ensuring the GDD471A001 delivers reliable performance throughout its 10-year design lifespan. Customers also gain access to online resources, including detailed wiring diagrams and diagnostic guides tailored to this model.