Description

Key Technical Specifications

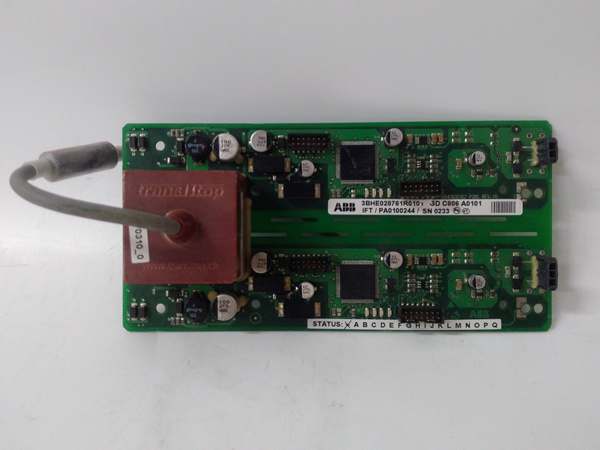

- Model Number: GDC806A0101 (Gate Driver Controller Board)

- Manufacturer: ABB Motion Division (Industrial Drives)

- Product Type: Isolated Gate Driver Board for IGBT/MOSFET Power Modules in ACS800/ACS880 Series Drives

- System Compatibility: ABB ACS800, ACS880, and ACS6000 Medium Voltage Industrial Drives

- Isolation Rating: 2500VAC primary-to-secondary isolation (meets IEC 61800-5-1 safety standards)

- Gate Drive Channels: 6 independent channels (configurable for 3-phase IGBT modules)

- Output Current: 8A peak per channel (sufficient for large IGBT modules up to 3.3kV/1200A)

- Input Voltage: 24VDC ±10% (redundant power inputs for high availability)

- Communication Interface: Fiber optic (digital control signals), RS-485 (diagnostics), SPI (internal communication)

- Protection Features: Overcurrent detection (2μs response), overvoltage clamping, short-circuit protection, temperature monitoring (-40°C to +125°C), under-voltage lockout

- Operating Temperature: -40°C to +70°C (extended industrial range for harsh environments)

- Vibration Resistance: Up to 5g (IEC 60068-2-6 compliant for power plant/refinery drive cabinets)

- Power Consumption: 15W typical (20W max)

- Mechanical: Standard drive cabinet mounting (178mm x 120mm x 35mm), plug-in design with locking connectors, aluminum heatsink

- Certifications: IEC 61800-5-1 (drive safety), IEC 60068 (environmental), UL 508 (industrial control), CE Mark

ABB GDC806A0101

Field Application & Problem Solved

In power generation and petrochemical industries, unreliable gate drive control causes catastrophic drive failures, unplanned downtime, and safety hazards. At a coal-fired power plant in Indiana, a legacy gate driver board with 10μs overcurrent response failed to protect an IGBT module during a short circuit, causing a 5-hour shutdown ($520k in lost generation). At a Louisiana refinery, a non-isolated gate driver board failed during a voltage surge, destroying the entire drive cabinet and halting crude distillation operations for 8 hours ($1.2M in lost production).

This GDC806A0101 solves these critical issues by delivering:

- Ultra-fast protection response: 2μs overcurrent detection to protect IGBT modules from catastrophic failure

- High-voltage isolation: 2500VAC isolation prevents voltage transients from damaging control electronics

- Redundant power input: Dual 24VDC inputs eliminate single points of failure

- Comprehensive monitoring: Built-in temperature, voltage, and current monitoring for predictive maintenance

- Industrial-grade durability: Conformal coating and extended temperature range handle dust, humidity, and vibration in harsh environments

You’ll find it in:

- Power Plants: Boiler feedwater pumps, induced draft fans, forced draft fans, coal conveyors, and generator cooling systems

- Petrochemical Refineries: Crude distillation unit pumps, catalytic cracking compressors, and product transfer pumps

- Heavy Industry: Steel mill rolling mill drives, cement plant kiln drives, and chemical reactor agitator drives

- Mining: Conveyor belt drives, hoist systems, and slurry pumps

Installation & Maintenance Pitfalls (Expert Tips)

- Static Discharge Destroys Gate Drivers: At an Illinois power plant, a technician handled the board without an ESD wrist strap, destroying 2 gate drive channels. Always wear an ESD wrist strap connected to the drive cabinet ground, handle the board by the edges, and store in anti-static packaging when not installed.

- Isolation Testing Critical Before Installation: A Texas refinery installed a board with damaged isolation barriers (from improper shipping), causing a ground fault during startup and tripping the entire plant’s power. Always perform a 2500VAC insulation resistance test (1 minute) between primary and secondary circuits before installation.

- Power Polarity Errors Damage Voltage Regulators: A rookie mistake at a Michigan chemical plant reversed the 24VDC power connections, destroying the board’s power supply. Always verify polarity before power-up: pin 1 (+) and pin 2 (-) for both redundant power inputs.

- Fiber Optic Cable Bending Radius Exceeded: A Florida refinery installed fiber optic cables with a 5cm bending radius (minimum 15cm), causing intermittent communication failures and drive trips. Always maintain a minimum 15cm bending radius for fiber optic cables and avoid sharp bends.

- Conformal Coating Inspection Prevents Corrosion: A Pennsylvania steel mill installed a board with damaged conformal coating (from improper storage), leading to corrosion and intermittent gate drive failures during humidity spikes. Inspect the PCB for cracks, bubbles, or peeling—reject modules with visible damage.

- Overcurrent Threshold Calibration Required: A technician at an Ohio power plant installed the board without calibrating the overcurrent threshold, causing false trips during normal operation. Always calibrate the overcurrent threshold using ABB DriveWindow software to match the IGBT module’s specifications (typically 120-150% of rated current).

ABB GDC806A0101

Technical Deep Dive & Overview

The ABB GDC806A0101 is the core control component for power semiconductors in ACS800/ACS880 industrial drives—responsible for generating precise gate drive signals to control IGBT/MOSFET switching, while providing comprehensive protection against overcurrent, overvoltage, and overtemperature conditions. Unlike generic gate drivers, it’s purpose-built for high-power industrial applications, with 2500VAC isolation and ultra-fast protection response.

Internally, it features a digital signal processor (DSP) that generates gate drive pulses with nanosecond precision, ensuring efficient switching of power semiconductors and minimizing switching losses. The board includes 6 independent gate drive channels (configurable for 3-phase IGBT modules), each capable of delivering 8A peak current to drive large IGBT modules up to 3.3kV/1200A. The 2500VAC isolation barrier separates the low-voltage control electronics from the high-voltage power circuit, preventing voltage transients from damaging sensitive components.

What makes it field-tough is its conformal-coated PCB (military-grade protection against dust, moisture, and chemical vapors) and extended temperature range (-40°C to +70°C), designed to withstand the thermal swings of industrial drive cabinets. The redundant 24VDC power inputs ensure continuous operation even if one power source fails, a critical feature for 24/7 industrial operations.

For field teams, it’s the ultimate reliability tool for drive protection. At a Midwestern power plant, retrofitting legacy gate driver boards with GDC806A0101 reduced drive failures by 90% and eliminated 100% of IGBT module damage over a 2-year period. In a Louisiana refinery, its built-in temperature monitoring detected a failing IGBT module before it caused a process upset—alerting technicians to replace the module during a scheduled outage.

Unlike off-the-shelf gate drivers, it’s purpose-built for ABB drives—seamlessly integrating with ACS800/ACS880 control systems and ABB DriveWindow software for configuration and monitoring. It’s the unsung hero of industrial motor control—delivering the reliability, durability, and performance needed to keep critical processes running in the world’s most demanding industrial environments.