Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | GCD207B101 |

| Manufacturer | ABB |

| Product category | Generator control device |

| Rated voltage | 110-250 V AC/DC |

| Power consumption | Max 15 W |

| Control functions | Speed regulation, voltage control, synchronization, protection |

| Communication protocols | Modbus RTU, CANopen, Ethernet/IP |

| Inputs | 8 analog inputs (4-20 mA/0-10 V), 16 digital inputs |

| Outputs | 4 analog outputs (4-20 mA), 8 digital outputs (relay) |

| Operating temperature | -25°C to 70°C |

| Dimensions | 180mm × 120mm × 80mm |

| Mounting type | Panel mount |

| Protection rating | IP42 (front), IP20 (rear) |

| Certifications | IEC 60947-1, CE, UL, ISO 8528 |

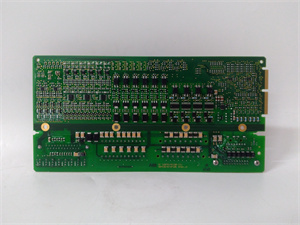

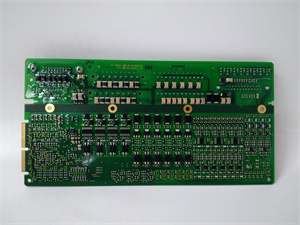

ABB GCD207B101

Product introduction

The ABB GCD207B101 is a comprehensive generator control device designed to manage and protect diesel, gas, or biogas generators in standby and prime power applications. As a key component in ABB’s power generation control portfolio, ABB GCD207B101 integrates speed regulation, voltage control, synchronization, and protection functions into a single compact unit, ensuring reliable operation of generator sets in industrial, commercial, and utility settings.

ABB GCD207B101 offers seamless integration with generator engines and alternators, providing precise control over key parameters such as frequency, voltage, and load sharing. Its flexible communication options enable remote monitoring and control via SCADA systems or HMI panels like the ABB XVC517AE10, while its robust design ensures performance in harsh environments. Whether deployed in data centers, hospitals, or remote off-grid installations, ABB GCD207B101 optimizes generator efficiency, enhances system reliability, and simplifies maintenance.

Core advantages and technical highlights

Integrated control and protection: ABB GCD207B101 combines speed regulation, voltage control, and protection functions (overcurrent, overvoltage, underfrequency) in one device, eliminating the need for separate controllers and reducing system complexity. In a hospital’s emergency power system, this integration ensures that if the generator exceeds safe voltage limits, the device can simultaneously trip the output breaker and reduce engine speed—preventing damage to both the generator and connected medical equipment.

Precise synchronization capabilities: Equipped with advanced synchronization algorithms, ABB GCD207B101 enables smooth parallel operation of multiple generators or connection to the utility grid. It adjusts frequency and voltage within ±0.1 Hz and ±1% of nominal values, minimizing inrush currents and voltage transients during switchover. For a manufacturing plant with three backup generators, this precision allows load sharing with a deviation of less than 2%, ensuring balanced wear and extending generator lifespan.

Flexible communication and remote monitoring: Supporting Modbus RTU, CANopen, and Ethernet/IP, ABB GCD207B101 facilitates data exchange with SCADA systems, HMI panels, and mobile devices. Operators can remotely monitor generator status (e.g., fuel level, coolant temperature) and adjust settings (e.g., target frequency) via a web interface or the ABB XVC517AE10 HMI. In a remote mining camp, this capability reduces the need for on-site visits, as technicians can diagnose issues and perform adjustments from a central control room.

Rugged design for harsh environments: ABB GCD207B101 operates reliably in temperatures ranging from -25°C to 70°C, making it suitable for outdoor installations in extreme climates. Its IP42 front protection guards against dust and water splashes, while its resistance to vibration (up to 10 g) ensures performance in mobile applications like generator trailers. In an oil field’s temporary power setup, this durability ensures consistent operation despite dust, temperature swings, and vehicle-induced vibrations.

Typical application scenarios

In a data center’s backup power system, ABB GCD207B101 controls two 2 MW diesel generators, ensuring seamless transition to backup power within 10 seconds of a grid failure. The device synchronizes the generators before connecting them to the critical load bus, balancing the load to within 50 kW of each other. Its Ethernet/IP connection to the data center’s BMS allows operators to monitor fuel consumption and runtimes, enabling predictive maintenance scheduling. The generator control device also integrates with the facility’s fire alarm system, automatically shutting down generators in case of a fire to prevent fuel leakage.

In a remote off-grid community powered by four biogas generators, ABB GCD207B101 manages load sharing and voltage regulation. It adjusts generator output based on community demand (e.g., increasing capacity during evening hours) and monitors biogas pressure to prevent engine stalls. The device communicates via Modbus RTU with a local HMI, allowing community technicians to view real-time data and receive alarms (e.g., low gas pressure) via SMS. Its wide temperature tolerance ensures reliable operation in the community’s sub-zero winter conditions.

ABB GCD207B101

Related model recommendations

ABB XVC517AE10 3BHB004744R0010: An industrial HMI that provides a visual interface for monitoring and controlling ABB GCD207B101.

ABB PM633: A PLC that works with ABB GCD207B101 to coordinate generator operation with other site systems (e.g., fuel storage).

ABB DSAO120 57120001-EY: An analog output module that can extend the control signal capabilities of ABB GCD207B101 in complex systems.

ABB 200900-004: A heavy-duty terminal block used to terminate power and sensor cables for ABB GCD207B101.

ABB CI858-1 3BSE018137R1: A communication module that enhances ABB GCD207B101’s connectivity to Ethernet-based networks.

ABB PPE091A101 3BHE044481R0101: A redundant power supply ensuring uninterrupted operation of ABB GCD207B101 in critical applications.

Installation, commissioning and maintenance instructions

Installation preparation: Mount ABB GCD207B101 on a flat panel using the provided brackets, ensuring 50mm clearance for ventilation. Connect the device to the generator’s engine control unit (ECU) via CANopen, and to the alternator via analog inputs for voltage and current sensing. Wire digital inputs for emergency stop, start/stop signals, and sensor alarms (e.g., low oil pressure). Connect 110-250 V AC/DC power using 1mm² shielded cable, protected by a 2A fuse. Use a torque screwdriver set to 1.2 Nm for terminal connections. Power off all systems during installation to avoid electrical hazards.

Maintenance suggestions: Inspect ABB GCD207B101 quarterly for loose connections, dust accumulation, and front panel damage. Clean the device with a dry cloth—avoid compressed air to prevent dust ingress. Verify calibration annually using a signal generator to ensure voltage and frequency measurements are within ±0.5% of nominal values. Test relay outputs semi-annually by simulating alarms and confirming proper switching. Update firmware annually via Ethernet to access the latest control algorithms. If communication faults occur, check cable integrity and protocol settings before replacing components—use only ABB-certified parts to maintain system compatibility.

Service and guarantee commitment

ABB GCD207B101 is backed by a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance standards. ABB’s power generation technical support team provides response within 4 hours for critical issues, with remote diagnostics available 24/7 to minimize generator downtime. On-site service is available within 72 hours in major regions for complex commissioning or repair needs.

The warranty includes free access to configuration software and firmware updates. Extended service contracts offer annual calibration, functional testing, and priority support, ensuring the device maintains optimal performance throughout its 15-year design lifespan. ABB’s commitment to quality underscores confidence in ABB GCD207B101 as a reliable controller for generator sets in critical power applications.