Description

Key Technical Specifications

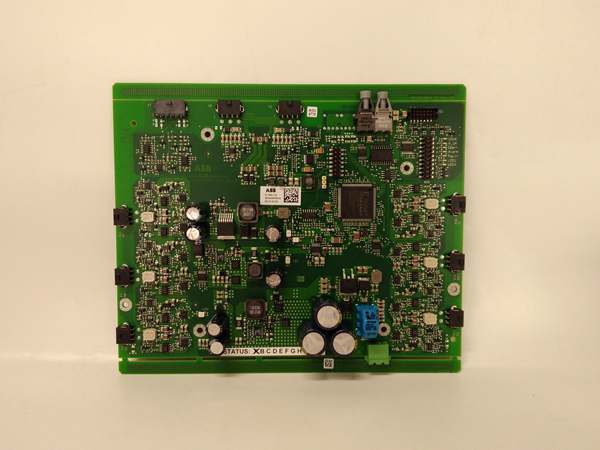

- Model Number: ABB GCC960C102

- Manufacturer: ABB

- Module Type: Generator central control & communication gateway

- Control Functions: Voltage regulation, synchronizing, load sharing, protection logic

- Power Supply: 110/220V DC ±10% (redundant input support)

- Communication Protocols: IEC 61850, MODBUS TCP/RTU, DNP3.0, IEC 60870-5-104

- Digital I/O: 32 configurable inputs, 16 configurable outputs (dry contact)

- Analog I/O: 8 analog inputs (4-20mA), 4 analog outputs (4-20mA)

- Operating Temperature: -20°C to 70°C (-4°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 2.5kV AC (control circuit to power circuit, 1-minute withstand)

- Processing Speed: 1GHz 32-bit microprocessor (real-time clock sync via PTP/IEEE 1588)

- Mounting: Panel mounting (19-inch rack compatible)

- Power Consumption: 65W (max load)

- Dimensions: 483mm x 177mm x 267mm (19” rack width)

- Weight: 5.2kg

- Protection Features: Overvoltage, undervoltage, short-circuit, and reverse polarity protection

ABB GCC960C102

Field Application & Problem Solved

In large-scale power generation—coal, gas, and hydroelectric plants—synchronous generators require centralized control that unifies regulation, protection, and data integration. The challenge? Legacy control systems use fragmented modules (separate voltage regulators, synchronizers, communication gateways) that create compatibility issues, slow data transfer, and complex maintenance. Others lack support for modern grid protocols (e.g., IEC 61850) or fail to provide centralized protection logic, leading to delayed fault responses and generator damage. The ABB GCC960C102 solves these pain points by combining master control, protection, and multi-protocol communication in a single, integrated module.

You’ll find this module as the “brain” of generator control systems in 50-500MW power plants, where it synchronizes generators to the grid, regulates voltage and load, and communicates with plant SCADA. It’s used in combined-cycle facilities to coordinate multiple generators, ensuring load sharing and efficient power output. In hydroelectric plants, it integrates with turbine controllers to adjust generator excitation based on water flow, maintaining stable voltage during variable load conditions. It’s also critical in grid-connected systems, where its IEC 61850 compliance enables seamless data exchange with transmission system operators (TSOs) for grid stability monitoring.

Its core value is integration and reliability. By consolidating multiple functions into one module, it eliminates wiring complexity and compatibility issues common with fragmented systems. The 1GHz processor ensures real-time processing of control logic and data, with sub-10ms response to faults—preventing generator damage from overexcitation or voltage surges. Multi-protocol support eliminates the need for separate gateways, reducing cabinet space and lifecycle costs. For plant operators, this means simplified maintenance, faster fault resolution, and compliance with modern grid standards—critical in an era of increasing renewable integration and strict TSO requirements.

Installation & Maintenance Pitfalls (Expert Tips)

- Redundant Power Supply Wiring (Single Source = Single Point of Failure): The module supports redundant 110/220V DC power inputs, but rookies often wire both inputs to the same power source. This defeats redundancy—if the source fails, the module shuts down, taking the generator offline. Wire each input to separate DC busbars (e.g., main and backup power) and install fuses (5A slow-blow) in each line. Verify redundancy by testing a power source shutdown during commissioning— the module should switch seamlessly without interrupting control.

- IEC 61850 Configuration (Incorrect Logical Nodes = Data Loss): For IEC 61850 communication, the module uses logical nodes (e.g., MMXU for measurements, REX for excitation) that must map to the SCADA system’s data model. Rookies often use default logical node names or skip mapping, leading to missing telemetry or incorrect data interpretation. Use ABB’s IEC 61850 Configuration Tool to define logical nodes, assign data attributes (e.g., generator voltage, field current), and verify the SCL (Substation Configuration Language) file with the SCADA vendor. Test data transmission for all critical points before going live.

- Synchronizing Input Wiring (Phase Mismatch = Generator Damage): The module’s synchronizing function relies on voltage and frequency inputs from both the generator and grid. Rookies often swap phase wires (A/B/C) between the generator and grid transducers, causing phase mismatch during synchronization. This results in catastrophic mechanical shock to the generator and turbine. Use a phase rotation meter to confirm correct wiring—generator phase A must align with grid phase A, B with B, and C with C. Perform a dry run (no load) to verify synchronizing logic before connecting the generator to the grid.

- Protection Logic Bypass (Temporary Bypass = Permanent Damage): During maintenance, rookies sometimes bypass the module’s protection logic (e.g., overexcitation limiter) to “speed up” testing. Even temporary bypasses leave the generator vulnerable to faults—an overexcitation event can damage the rotor windings in seconds. Never bypass protection functions unless following ABB’s approved lockout-tagout procedures, and always restore them immediately after testing. Use the module’s “test mode” instead, which simulates protection triggers without disconnecting the control loop.

ABB GCC960C102

Technical Deep Dive & Overview

The ABB GCC960C102 is a centralized master control module designed for large synchronous generators, serving as the hub for regulation, protection, and communication in power plant control systems. Its core is a 1GHz 32-bit microprocessor paired with field-programmable gate arrays (FPGAs) that handle real-time control logic and I/O processing—enabling sub-10ms response to dynamic load changes and faults. The module’s architecture follows a “control-by-wire” philosophy, integrating voltage regulation, synchronizing, load sharing, and protection functions into a unified software platform.

The module’s I/O section includes configurable digital and analog channels that interface with field devices: voltage transformers (VTs) and current transformers (CTs) for generator parameters, contactors for breaker control, and transducers for field current monitoring. The analog inputs use 16-bit ADCs for high-precision measurements, while the outputs provide isolated drive signals for external actuators. Redundant power inputs ensure uninterrupted operation, with automatic failover between sources.

Communication is a key strength— the module supports IEC 61850 (for substation automation), MODBUS TCP/RTU (for legacy SCADA), DNP3.0 (for utility communication), and IEC 60870-5-104 (for TSO integration). A dedicated Ethernet switch with PTP (IEEE 1588) support enables time-synchronized data transfer, critical for coordinating multiple generators in a plant. The module’s non-volatile memory stores configuration files, fault logs, and event records, accessible via local HMI or remote SCADA.

Protection logic is embedded in the software, including overexcitation/underexcitation limiters, overvoltage/overcurrent trip, and loss-of-field protection. These functions are configurable to match the generator’s rated parameters, with user-adjustable setpoints and time delays. The module also includes auto-synchronizing logic that aligns generator voltage, frequency, and phase with the grid before closing the main breaker—preventing mechanical shock and electrical damage.

Built for industrial ruggedness, the GCC960C102 features a 19-inch rack-mount metal housing with IP54 protection, shielding against dust and water spray. It withstands vibration (up to 3g at 10-2000Hz) and temperature extremes (-20°C to 70°C), suitable for power plant control rooms and outdoor skids. The module’s hot-swappable design (with redundant units) allows replacement without shutting down the generator, minimizing downtime. Its long-term reliability is validated by ABB’s compliance with IEC 61508 (SIL 2) for functional safety, ensuring it meets the strictest power industry standards.