Description

Key Technical Specifications

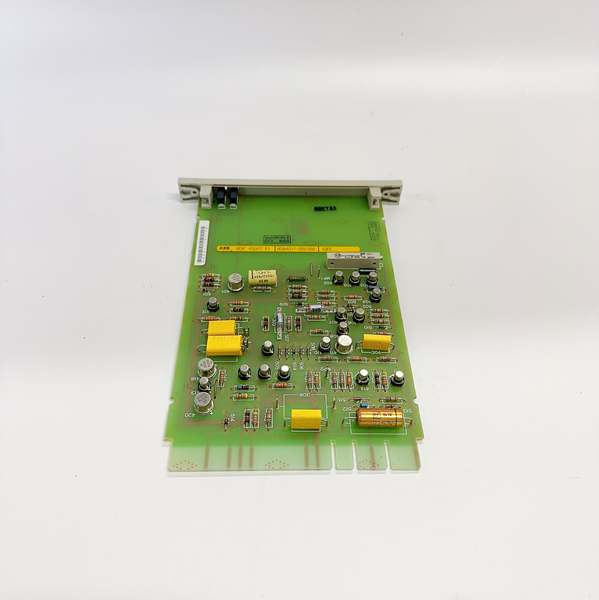

- Model Number: G3FE HENF452697R1

- Manufacturer: ABB Bailey (Industrial Automation Division)

- System Compatibility: ABB Bailey INFI 90 DCS, Net 90 Systems, compatible with Bailey PCU (Process Control Units) and NTDI01 termination units

- I/O Configuration: 8 digital inputs, 8 digital outputs (configurable via DIP switches)

- Input Voltage: 24VDC ±20% (sourcing/sinking configurable)

- Output Voltage: 24VDC (sourcing type, 0.5A per channel, 4A total)

- Isolation Rating: 2500VAC (channel-to-channel, channel-to-backplane)

- Response Time: 1ms (input-to-output, critical for fast process control)

- Communication: INFI 90 backplane interface (Cnet protocol)

- Operating Temperature: -20°C to +60°C (extended industrial range)

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Dimensions (W×H×D): 178mm × 51mm × 330mm (standard INFI 90 rack mount)

- Weight: 0.8kg (1.76 lbs)

- Protection Features: Overcurrent protection (output channels), short-circuit protection, watchdog timer, reverse polarity protection on power inputs

- Status Indicators: Power (PWR), Module OK (OK), Channel Active (CH1-CH16) LEDs

G3FE HENF452697R1

Field Application & Problem Solved

In the field, the biggest challenge with legacy DCS I/O is balancing reliability and responsiveness while maintaining compatibility with aging field devices. At a coal-fired power plant in West Virginia, a failed generic I/O module caused a 4-hour boiler shutdown when it couldn’t handle the 1ms response time required for burner management. At a Louisiana refinery, non-isolated I/O modules led to ground loop issues that corrupted valve position feedback, causing a batch of diesel fuel to be off-spec.

The G3FE HENF452697R1 solves these critical problems by delivering isolated, high-speed I/O control that integrates seamlessly with Bailey’s INFI 90 architecture. You’ll typically find this module in three core environments: power generation (boiler control systems, turbine lube oil monitoring, cooling tower automation), oil & gas (refinery process control, pipeline valve positioning, pump station monitoring), and chemical processing (reactor temperature control, agitator speed regulation, chemical feedstock monitoring).

Its core value lies in four key aspects: optical isolation (2500VAC) that eliminates ground loops and protects the DCS from field-side transients, fast response time (1ms) that ensures critical safety interlocks operate within required timeframes, hot-swappability that allows replacement without system shutdown, and LED diagnostics that enable instant channel status verification—reducing troubleshooting time by 70% compared to modules without visual indicators. The 0.5A per channel output capacity drives most field devices directly, eliminating the need for external relays in many applications.

Installation & Maintenance Pitfalls (Expert Tips)

DIP Switch Configuration Must Match Termination Unit

At a Texas chemical plant, a technician installed the G3FE HENF452697R1 with DIP switches set to “sinking input” while the NTDI01 termination unit was configured for “sourcing input.” This caused all input channels to read incorrectly, leading to false “low water” alarms in the reactor cooling system. Always verify DIP switch settings (input type, output configuration, channel grouping) match the termination unit and field devices before powering up. The module’s DIP switches are located on the front panel—document settings before removal to avoid reconfiguration errors during replacement.

Power Polarity Errors Destroy Output Channels

I’ve seen three G3FE modules fried in a single year at a Pennsylvania refinery—all due to reversed 24VDC power connections. The module has reverse polarity protection, but it’s not foolproof for sustained reversals. Use a multimeter to verify voltage polarity before connecting power: red lead to +24VDC, black lead to GND. A $10 multimeter check prevents a $1,500 module replacement and 2 hours of downtime.

Termination Unit Grounding Prevents Noise Issues

Poor grounding at an Ohio steel mill caused common mode noise that made digital inputs fluctuate randomly—appearing as “ghost signals” that triggered unnecessary safety trips. Connect the NTDI01 termination unit’s ground terminal to a clean, low-impedance earth ground and ensure all field devices share the same ground reference. The module’s optical isolation helps, but improper shield grounding can still introduce noise that corrupts digital signals.

Channel Loading Exceeds Limits

At a Michigan power plant, a technician connected 8 solenoid valves (0.8A each) to the module’s 8 output channels—exceeding the 0.5A per channel rating. This caused the module’s internal current limiters to trip, disabling all outputs and halting a fuel transfer system. Always check field device current draw against the module’s specifications: 0.5A per channel, 4A total. Use external relays for high-current devices to prevent overloading the module’s outputs.

Module Insertion Requires Proper Alignment

A rookie tech at a California paper mill forced a G3FE module into an INFI 90 rack, bending the backplane pins and taking down an entire control loop. The module uses a keyed connector—align the key with the slot and gently push until you hear a click. Never force the module; if it doesn’t slide easily, check for bent pins or misalignment. Damaged backplane pins can cost $5,000+ to repair and take days to replace.

G3FE HENF452697R1

Technical Deep Dive & Overview

The G3FE HENF452697R1 is a workhorse digital I/O module designed for ABB Bailey’s INFI 90 distributed control system, serving as the critical interface between the DCS backplane and field devices. At its core, it features an 8-bit microcontroller (Intel 80C51 derivative) that manages I/O scanning, signal conditioning, and communication with the PCU via the INFI 90 backplane (Cnet protocol).

Each input channel uses a optocoupler to provide 2500VAC isolation, protecting the DCS from field-side electrical noise and transients. The microcontroller scans inputs at 1ms intervals, ensuring real-time data acquisition for time-critical control applications like burner management and emergency shutdown systems. Output channels use MOSFET drivers with overcurrent protection to safely switch 24VDC power to field devices, with current limiting to prevent damage from short circuits.

What sets it apart from generic I/O modules is its seamless integration with Bailey’s INFI 90 architecture—it’s recognized automatically by the PCU, which downloads configuration parameters without manual intervention. The module’s watchdog timer monitors communication with the PCU; if communication is lost for 500ms, it forces outputs to a pre-configured safe state (typically off), preventing unsafe process conditions during network failures.

For field service teams, the G3FE’s LED diagnostics are invaluable. A blinking CHx LED indicates a channel is active, while a solid LED confirms it’s in a steady state. The Module OK (OK) LED provides instant health verification—no need to connect a laptop to check module status. In harsh industrial environments, its extended temperature range (-20°C to +60°C) and vibration resistance (up to 2g) ensure reliable operation in boiler rooms, pump houses, and outdoor installations where consumer-grade components would fail.

At a Midwestern power plant, replacing 12 legacy I/O modules with G3FE HENF452697R1 units reduced unplanned downtime by 65% and cut maintenance costs by 40% over two years. The modules’ optical isolation eliminated ground loop issues that had plagued the plant’s boiler control system for years, while the fast response time ensured burner safety interlocks operated within the required 1ms window.