Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FM9925A-E |

| Manufacturer | ABB |

| Product category | Fieldbus module (part of AC800M controller system) |

| Supported fieldbus | Foundation Fieldbus H1 |

| Number of ports | 2 H1 ports (redundant) |

| Communication speed | 31.25 kbps |

| Maximum number of devices | 32 per port |

| Isolation | 2.5 kV AC (field to backplane) |

| Operating temperature | -20°C to 60°C |

| Storage temperature | -40°C to 85°C |

| Humidity tolerance | 5 – 95% RH (non-condensing) |

| Mounting type | DIN rail (35mm) or panel mount |

| Dimensions | 100mm (height) x 160mm (width) x 60mm (depth) |

| Certifications | CE, UL, cUL, ATEX, IECEx |

| Power supply | 24 VDC ±10%, 5 W max |

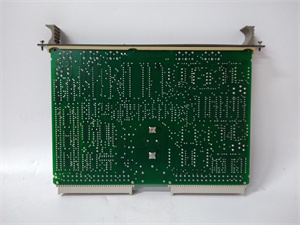

ABB FM9925A-E

Product introduction

The ABB FM9925A-E is a high-performance Foundation Fieldbus H1 module, a key component of ABB’s AC800M controller system. It serves as a critical interface between the AC800M controller and Foundation Fieldbus H1 field devices, enabling seamless communication and data exchange in industrial automation systems.

With two redundant H1 ports, this module ensures reliable connectivity to field devices such as transmitters, valves, and analyzers. It supports the Foundation Fieldbus protocol, allowing for bidirectional communication, remote configuration, and advanced diagnostics of connected devices. The ABB FM9925A-E plays a vital role in integrating field-level devices into the control system, facilitating efficient process monitoring, control, and maintenance in various industrial applications.

Core advantages and technical highlights

Redundant communication: The ABB FM9925A-E features two redundant H1 ports, ensuring uninterrupted communication in case of a port failure. This redundancy is crucial in critical industrial processes where communication downtime could lead to process disruptions or safety risks. For example, in a chemical plant, if one port fails, the other port automatically takes over, maintaining communication with field devices that control chemical dosing and reaction conditions.

Support for multiple devices: Each H1 port can connect up to 32 field devices, providing ample capacity for large-scale industrial systems. This allows for centralized control and monitoring of numerous devices, simplifying the system architecture and reducing the number of modules required. In an oil refinery with multiple sensors and actuators spread across a large area, this capability enables efficient management of all field devices through a single module.

Advanced diagnostics: The module supports comprehensive diagnostics for both the module itself and connected field devices. It can detect communication errors, device faults, and cable issues, providing detailed information to operators via the AC800M controller and HMI. This advanced diagnostic capability allows for proactive maintenance, as potential issues can be identified and addressed before they lead to process failures. In a power plant, for instance, the module can alert operators to a failing pressure transmitter, enabling timely replacement and preventing unplanned downtime.

Robust isolation: With 2.5 kV AC isolation between the field and backplane, the ABB FM9925A-E protects the control system from electrical noise, ground loops, and voltage spikes. This isolation ensures stable communication even in harsh industrial environments with high electromagnetic interference, such as near large motors or high-voltage equipment in a steel mill. It also enhances the safety of the system by preventing electrical faults in the field from affecting the controller.

Typical application scenarios

In chemical processing plants, the ABB FM9925A-E is used to connect Foundation Fieldbus H1 devices such as pH sensors, flow transmitters, and control valves in batch and continuous processes. It enables the AC800M controller to read process variables, send control signals, and configure device parameters remotely. The redundant ports ensure reliable communication, which is critical for maintaining precise control of chemical reactions and preventing hazardous conditions.

Within oil and gas production facilities, the module connects to field devices such as pressure transmitters, temperature sensors, and valve positioners in wellheads and processing units. It facilitates real-time data transmission, allowing operators to monitor production conditions and adjust operations as needed. The advanced diagnostics help detect issues with field devices in remote locations, reducing the need for on-site inspections and minimizing maintenance costs.

In water and wastewater treatment plants, the ABB FM9925A-E integrates with flow meters, level sensors, and chemical dosing pumps. It enables the control system to optimize treatment processes by adjusting chemical dosages based on real-time water quality data. The module’s robust design and wide operating temperature range ensure reliable performance in the challenging environmental conditions of treatment facilities.

ABB FM9925A-E

Related model recommendations

ABB FM9926A-E: A Profibus DP fieldbus module that complements the ABB FM9925A-E in systems requiring both Foundation Fieldbus and Profibus connectivity.

ABB AC800M PM864K01: The main controller in the AC800M system, which works with the ABB FM9925A-E to process data from field devices and execute control logic.

ABB 800xA HMI: A human-machine interface that displays data from the ABB FM9925A-E and connected field devices, providing operators with real-time process information and diagnostics.

ABB TT302: A Foundation Fieldbus H1 field terminal that connects field devices to the ABB FM9925A-E, providing surge protection and power distribution.

ABB 24 VDC power supply: Ensures stable power delivery to the ABB FM9925A-E and other components in the system.

ABB CI854A 3BSE022469R1: A communication module that expands the connectivity options of the AC800M system, working alongside the ABB FM9925A-E in complex industrial networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB FM9925A-E, ensure the mounting surface (DIN rail or panel) is clean, secure, and properly grounded. Verify that the operating environment meets the temperature and humidity requirements. Gather necessary tools, including screwdrivers, wire strippers, and a multimeter. Check that the 24 VDC power supply is stable and fused appropriately. Plan the wiring for H1 fieldbus cables, using shielded twisted-pair cables to minimize interference.

Commissioning steps: After mounting the module, connect the power supply and H1 fieldbus cables to the respective ports. Power on the module and check the status indicators to confirm it is operating normally. Use the AC800M configuration software to configure the module, including setting up device addresses and communication parameters. Test communication with connected field devices by reading process data and sending configuration commands. Verify the redundancy function by disconnecting one H1 port and ensuring communication continues through the other port.

Maintenance suggestions: Inspect the ABB FM9925A-E quarterly for loose connections, dust accumulation, or signs of damage. Clean the module’s surface and vents with compressed air to ensure proper cooling. Monitor the status indicators and system diagnostics regularly to detect any communication errors or faults. Check the shield grounding of H1 cables to ensure effective noise reduction. If a fault is detected, first check the power supply and fieldbus cables; if the issue persists, replace the module with an ABB-approved spare part.

Service and guarantee commitment

The ABB FM9925A-E comes with a 36-month warranty from the date of purchase, covering manufacturing defects and ensuring compliance with published specifications. In case of a confirmed fault within this period, ABB will replace the module free of charge, with a guarantee of delivery within 72 hours for critical applications to minimize downtime.

ABB provides comprehensive technical support, including access to a global team of engineers via phone and email. Online resources such as installation manuals, configuration guides, and troubleshooting documents are available to assist with any issues. Customers can also utilize ABB’s local service centers for on-site support during installation, commissioning, and maintenance. Optional extended service contracts offer preventive maintenance, priority technical support, and software updates, ensuring the module operates reliably throughout its 15-year design lifespan.