Description

Key Technical Specifications

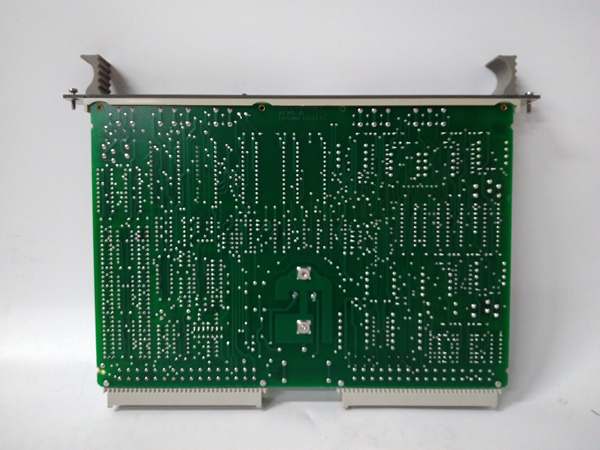

- Model Number: ABB FM9925A-E

- Manufacturer: ABB

- Device Type: Three-phase full-wave thyristor (SCR) rectifier module

- Thyristor Configuration: 6 x high-power SCRs (3-phase bridge)

- Rated Current: 250A (continuous), 500A (peak surge, 10ms)

- Rated Voltage: 1600V DC (reverse blocking voltage)

- Control Signal Input: 0-10V DC or 4-20mA (phase angle control)

- Operating Temperature: -40°C to 120°C (-40°F to 248°F)

- Storage Temperature: -55°C to 150°C (-67°F to 302°F)

- Isolation: 3kV AC (module-to-ground, 1-minute withstand)

- Thermal Resistance: 0.12°C/W (junction-to-heatsink)

- Mounting: Direct heatsink mounting (compatible with ABB rectifier skids)

- Cooling Requirement: Forced air (8 m/s) or liquid cooling (15 L/min minimum)

- Power Consumption: 3.5W (control circuit), 4.8kW (power dissipation @ full load)

- Connector Type: Heavy-duty copper busbar terminals (M16 studs)

- Weight: 7.8 kg (17.2 lbs)

ABB FM9925A-E

Field Application & Problem Solved

In high-power industrial environments—power plants, steel mills, and large-scale manufacturing—converting AC to regulated DC for critical systems (generator excitation, heavy-duty drives, electrolysis processes) demands robust, high-current rectification. The challenge? Standard diode rectifiers lack adjustable output, while low-rated thyristor modules fail under continuous high-current loads or thermal stress. Many modules also suffer from poor phase control precision, leading to unstable DC output that damages sensitive equipment like generator rotor windings. The ABB FM9925A-E solves these issues with phase-controlled thyristor technology, high-current capacity, and rugged thermal design.

You’ll find this module in applications like providing regulated DC for generator field excitation in coal-fired power plants, supplying high-current DC to rolling mill drives in steel mills, or powering electrolysis cells in chemical manufacturing. It’s a core component in ABB’s large-scale rectifier systems, where it works alongside excitation controllers (e.g., GCC960 series) to deliver precise DC voltage/current for critical processes. In marine power systems, it’s used to convert shipboard AC to DC for propulsion drives, leveraging its wide temperature range (-40°C to 120°C) to withstand harsh sea conditions. It also excels in retrofits, replacing obsolete thyristor modules that can’t meet modern load demands or safety standards.

Its core value is precision and durability under extreme load. The phase-controlled SCRs allow smooth adjustment of DC output (0-100% of rated voltage), critical for matching generator excitation to load changes. The 250A continuous current rating and 500A surge tolerance handle peak demands without thermal shutdown, a common failure point in lower-rated modules. The rugged thyristor assembly resists voltage transients and thermal cycling, extending service life in 24/7 industrial environments. For operators, this means stable DC power, minimal unplanned downtime, and reduced maintenance costs—critical in applications where power interruptions cost thousands per minute.

ABB FM9925A-E

Installation & Maintenance Pitfalls (Expert Tips)

- Heatsink Preparation (Contamination = Thermal Failure): The module dissipates massive heat (4.8kW at full load), so rookies often neglect heatsink cleaning. Oil, dust, or corrosion on the heatsink mating surface creates air gaps, increasing thermal resistance and causing SCR overheating. Clean the heatsink with isopropyl alcohol and a lint-free cloth, then apply a thin, uniform layer (0.2mm) of ABB-specified thermal compound (3M 4416). Torque mounting bolts to 30 Nm—too loose, and heat transfer fails; too tight, and the module’s base plate warps, cracking SCR connections.

- Busbar Alignment & Torque (Misalignment = Arcing): The M16 busbar studs carry 250A continuous current, so poor alignment or under-torquing is catastrophic. Rookies often force misaligned busbars onto studs, creating mechanical stress that fractures connections over time. Align busbars parallel to the module’s terminals and use a calibrated torque wrench set to 65 Nm for copper busbars (70 Nm for aluminum). Retorque after the first week of operation—thermal cycling can loosen connections, leading to arcing and busbar damage.

- Control Signal Wiring (Noise = Erratic Output): The 0-10V DC/4-20mA control signal is sensitive to electromagnetic interference (EMI), but rookies often run control wires alongside high-voltage busbars. EMI induces noise, causing erratic phase control and unstable DC output. Use shielded twisted-pair (STP) cable for control signals, route them at least 60cm away from power cables, and ground the shield at the controller end only (single-point grounding). For long runs (over 100 meters), use a signal conditioner to boost immunity to noise.

- Skipping Pre-Commissioning SCR Testing (Latent Faults = Startup Failures): New modules can have hidden SCR defects (e.g., open gates, shorted junctions), but rookies often skip testing. Use a thyristor tester to verify each SCR: check forward blocking voltage (should exceed 1600V) and gate trigger response (trigger voltage 1-2V DC). A faulty SCR causes unbalanced three-phase rectification, leading to DC ripple, generator vibration, or module shutdown on startup. Replace any SCR that fails testing—don’t attempt to commission with a defective component.