Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

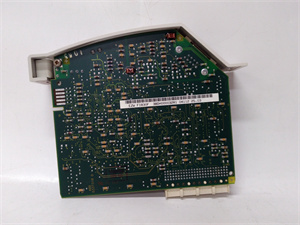

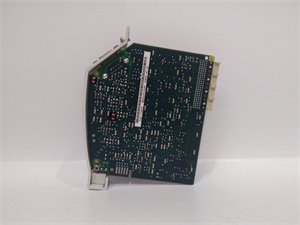

| Product Model | FI830F |

| Manufacturer | ABB |

| Product Category | PROFIBUS DP Fieldbus Interface |

| Bus Protocol | PROFIBUS DP-V1 |

| Data Transfer Rate | 9.6 kbps to 12 Mbps |

| I/O Connection | S800 I/O Modules (max 64 modules) |

| Electrical Isolation | 500 V AC between bus and logic |

| Power Supply | 24 VDC (19.2–30 VDC) |

| Operating Temperature | -25°C to +70°C |

| Certifications | CE, UL, ATEX/IECEx (Zone 2) |

| MTBF | >300,000 hours |

| Physical Dimensions | 118 x 129 x 119 mm (H x W x D) |

| Connection Interface | 9-pin D-Sub (PROFIBUS) |

ABB FI830F

Product Introduction

The ABB FI830F is a high-performance PROFIBUS DP-V1 interface module designed for ABB’s modular S800 I/O system. As a critical component of ABB’s Industrial Automation ecosystem, this fieldbus gateway enables seamless integration between PROFIBUS DP networks and ABB’s distributed I/O architecture. The FI830F acts as a decentralized peripheral station, allowing real-time data exchange with PLCs/DCS controllers like AC 800M while supporting advanced PROFIBUS features such as non-cyclic data transfer and diagnostics.

Engineered for harsh industrial environments, the ABB FI830F provides galvanic isolation between fieldbus and control systems, protecting sensitive electronics from electrical surges. Its compact design supports flexible mounting in control cabinets or field enclosures, while ATEX/IECEx Zone 2 certification ensures safe operation in explosive atmospheres. The module serves as a data concentrator, enabling cost-effective extension of control networks without additional wiring complexity.

Core Advantages and Technical Highlights

Robust Connectivity:

The ABB FI830F supports 12 Mbps PROFIBUS DP-V1 communication with GSD file configuration, enabling plug-and-play integration with Siemens, Rockwell, and other third-party masters. Redundant bus connectors simplify daisy-chaining without external terminators.

Diagnostic Capabilities:

Integrated LEDs provide real-time status for power, bus activity, and module errors. Detailed diagnostic data (station failure, configuration mismatch, cable breaks) is accessible via controller engineering tools, reducing mean-time-to-repair (MTTR) by 40%.

Scalable Architecture:

A single FI830F interfaces with up to 64 S800 I/O modules (e.g., AI810, DI810), supporting 1024 I/O points. Hot-swappable design allows module replacement without network shutdown.

Harsh Environment Resilience:

Operates at -25°C without preheating and withstands 95% humidity. Electromagnetic compatibility (EMC) exceeds EN 61000-6-2/4 standards for industrial noise immunity.

Typical Application Scenarios

In automotive manufacturing, the ABB FI830F connects robotic welding cells to central controllers via PROFIBUS, synchronizing 500+ I/O points across body-in-white assembly lines. Its 12 Mbps bandwidth ensures millisecond-level response for safety door interlocks.

Pharmaceutical plants utilize the FI830F to interface cleanroom sensors (pressure, humidity) with ABB’s 800xA DCS. ATEX certification allows deployment in solvent handling areas, while non-cyclic data reads enable batch recipe downloads to intelligent valve actuators.

Water treatment facilities deploy the module for pump station control, linking motor starters and flow meters over 1.2 km PROFIBUS segments. Galvanic isolation prevents ground loop interference in electrically noisy environments.

Related Model Recommendations

AI810: 8-channel analog input module for FI830F signal acquisition.

DI810: 16-channel digital input module with wet contact support.

TA521: S800 termination assembly for redundant power distribution.

CI854: Ethernet communication interface (alternative to PROFIBUS).

SD822: High-density 32-channel digital input module.

FI820F: Foundation Fieldbus interface module (same S800 platform).

AC 800M: Controller family for FI830F integration.

ABB FI830F

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify PROFIBUS cable shield continuity (<10 Ω). Use 24VDC power supplies with <5% ripple. Mount FI830F on DIN rail (EN 60715) with minimum 20mm clearance above for ventilation. Ground chassis via 4 mm² wire to central grounding point.

Maintenance Suggestions:

Monthly: Inspect PROFIBUS connectors for corrosion; clean with IPA if needed. Monitor “Bus Error” counters in Control Builder M software. Annually: Tighten power terminals to 0.5 N·m torque. Replace modules during planned shutdowns using ABB’s online removal procedure. Store configuration backups on SD card.

Service and Guarantee Commitment

ABB offers a 24-month warranty for the FI830F, covering material and manufacturing defects. Global technical support includes:

24/7 access to online documentation and GSD files

Remote diagnostics via System 800xA Asset Optimization

On-site assistance within 48 hours for critical failures

Extended lifecycle support guarantees spare parts availability for 10 years after discontinuation. All FI830F modules undergo 168-hour burn-in testing with thermal cycling (-25°C to +70°C) before shipment.