Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

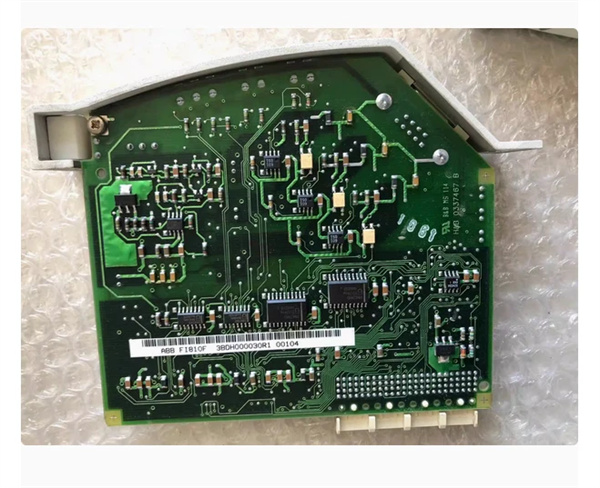

| Product Model | FI810F 3BDH000030R1 |

| Manufacturer | ABB |

| Product Category | Foundation Fieldbus H1 Interface Module (AC 800M) |

| Bus Interfaces | 2x FF H1 (IEC 61158-2) with 16.5kV isolation |

| Max Field Devices Supported | 16 per segment (32 total) |

| Communication Speed | 31.25 kbit/s |

| Power Output | 20-32 V DC, 450 mA per segment (FISCO Entity) |

| Diagnostic Resolution | ±0.1% FS (signal integrity monitoring) |

| Isolation Barrier | Galvanic isolation between bus/controller |

| LED Indicators | Per segment: Power, Activity, Fault |

| Operating Temperature | -40°C to +70°C |

| Certifications | ATEX/IECEx Ex ia, FM/CSA Cl I Div 2, SIL 2 |

| MTBF | >180,000 hours |

| Connection Type | Removable screw terminals |

ABB FI810F 3BDH000030R1

Product Introduction

The ABB FI810F 3BDH000030R1 is an intrinsically safe Foundation Fieldbus H1 interface module for ABB’s flagship AC 800M high-integrity process control system. Engineered for hazardous environments, this module bridges intelligent field devices (transmitters, positioners, analyzers) with the DCS backbone using IEC 61158-2 physical layer technology. As a critical component of ABB’s System 800xA architecture, the FI810F supports full FOUNDATION™ fieldbus functionality including control-in-field (CIF), advanced diagnostics, and live parameter reconfiguration.

Designed for mission-critical applications, the module provides dual-segment redundancy with automatic bus management, enabling continuous operation during communication faults. Its integrated power conditioning delivers FISCO-compliant power to field devices while maintaining Ex ia intrinsic safety certification for Zone 0/Division 1 areas. The ABB FI810F 3BDH000030R1 reduces wiring costs by up to 70% compared to traditional 4-20mA systems while enabling predictive maintenance through real-time device diagnostics.

Core Advantages and Technical Highlights

Hazardous Area Compliance:

Certified for ATEX/IECEx Ex ia [Ex ia IIC T4 Ga] and FM Cl I Div 1, the FI810F eliminates the need for external barriers in gas environments. FISCO entity parameters ensure safe energy limitation without complex calculations.

Deterministic Communication:

Precision clock synchronization (<1μs jitter) enables time-stamped process alarms and valve signature analysis. The module’s token-passing scheduler guarantees 31.25 kbit/s bandwidth allocation for critical control loops.

Advanced Diagnostics:

Continuous monitoring of bus voltage, current draw, and signal distortion detects field issues like cable degradation or moisture ingress before failures occur. Per-device communication statistics are accessible via Control Builder M engineering tools.

Scalable Architecture:

Each FI810F supports 32 devices across two segments. Hot-swappable design allows module replacement without process interruption. Segment redundancy maintains communication if one bus fails.

Cybersecurity Integration:

Embedded hardware firewall filters unauthorized fieldbus access. Supports device authentication and configuration change auditing per ISA/IEC 62443 standards.

Typical Application Scenarios

Offshore Gas Compression: Connects SIL 2-certified pressure transmitters and emergency shutdown valves in FPSO engine rooms, using Ex ia protection for methane-rich environments.

Pharmaceutical Bioreactors: Integrates multiparameter pH/DO sensors and smart valves for FDA-compliant batch processes, enabling live tuning of PID blocks during fermentation.

Refinery Crude Distillation: Manages 120+ temperature points across distillation columns using 8-channel FI810F segments, replacing 960 individual analog wires.

LNG Liquefaction Trains: Implements control-in-field for cascade refrigeration loops, reducing DCS scan time by 300ms per cycle.

Wastewater Anaerobic Digesters: Monitors biogas composition via FF-enabled analyzers with H2S corrosion diagnostics predictive maintenance.

ABB FI810F 3BDH000030R1

Related Model Recommendations

FI830F: Redundant FF H1 module for critical applications requiring 1:1 backup.

PM866: AC 800M controller processor pairing with FI810F for FF integration.

TA810F: FF H1 terminator module for bus impedance matching.

SD832: Diagnostic module for monitoring FI810F communication health.

CI854: PROFIBUS DP interface for non-FF device integration.

LD800H: FF linking device for remote I/O applications.

PP886: Redundant power supply for AC 800M racks hosting FI810F.

S800 I/O Baseplate: Mounting hardware for module installation.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

De-energize AC 800M rack before insertion. Verify trunk/spur wiring complies with FF-830 specification. Use shielded twisted-pair cables (Type A) with maximum 1,900m trunk length. Maintain 30cm separation from high-voltage cables. Ground shields at single point per FISCO rules.

Maintenance Protocol:

Perform quarterly bus diagnostics via FieldCare software. Monitor segment current draw – deviations >5% indicate potential issues. Replace modules showing persistent CRC errors. Calibrate field devices via live reconfiguration without process disruption. Upgrade firmware during planned shutdowns using Control Builder M.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the FI810F 3BDH000030R1, covering hardware defects and firmware functionality. Comprehensive support includes:

24/7 technical assistance for segment troubleshooting

FOUNDATION fieldbus configuration template libraries

On-site commissioning support within 48 hours

Lifetime firmware updates with backward compatibility

Loaner module program for critical processes

Extended service plans cover preventive maintenance, cybersecurity audits, and hot-spare provisioning. All modules undergo 168-hour burn-in testing with full load simulation. ABB’s certified training centers offer FF engineering certification programs.