Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FFVO142 3BSE223732R0001 |

| Manufacturer | ABB |

| Product category | Industrial automation control equipment (presumably for rolling – related applications considering similar models) |

| Input voltage range | 380 – 480 VAC |

| Output voltage range | 0 – 480 VAC |

| Dimensions (approx.) (WxHxD in mm) | [If available, insert here. Otherwise, mention as ‘Details to be added’] |

| Weight | [If available, insert here. Otherwise, mention as ‘Details to be added’] |

| Country of origin | [If available, insert here. Otherwise, mention as ‘Details to be added’] |

| Control function | Primarily designed for rolling force control in metal rolling processes (inferred from similar models like PFVO142) |

| Control mode | Supports multiple control modes for high – precision operation |

| Speed range | Adjustable from 0 Hz to motor – rated speed to meet diverse equipment requirements |

| Communication interfaces | Equipped with multiple interfaces such as Profibus and Modbus for seamless integration with existing control systems |

| Protection features | Incorporates overcurrent, over – temperature, and other safety mechanisms to enable emergency shutdowns and protect the device and connected equipment |

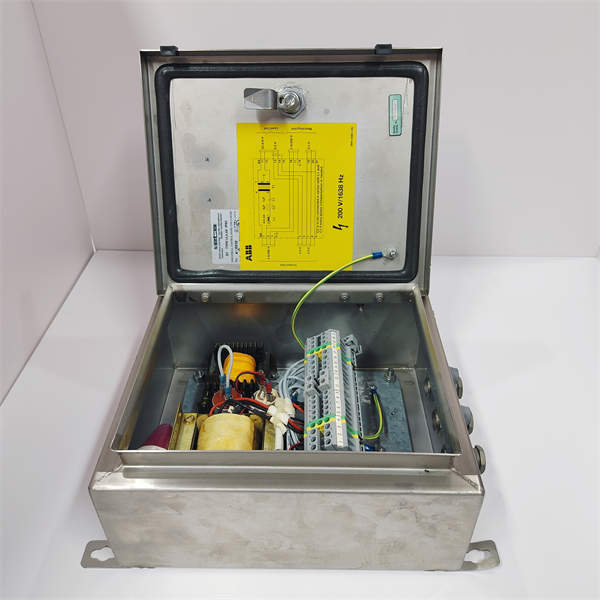

ABB FFVO142 3BSE223732R0001

Product introduction

The ABB FFVO142 3BSE223732R0001 is a sophisticated industrial automation control device that plays a pivotal role in various industrial sectors. Engineered by ABB, a globally recognized leader in industrial technology, this product is designed to meet the stringent demands of modern manufacturing processes.

Based on the characteristics of similar ABB products in the same product line, it is highly likely that the FFVO142 3BSE223732R0001 is focused on providing precise control in critical industrial operations. In the context of metal rolling processes, it is expected to regulate rolling forces with great accuracy. By adjusting the current to manipulate magnetic field strength, it can ensure that the rolling force is precisely tuned, which is crucial for producing high – quality metal products with consistent thickness and surface finish.

This device is not only limited to metal rolling but can also find applications in a wide range of industries such as steel, metallurgy, chemical, food processing, and power generation. In each of these sectors, its ability to offer reliable and accurate control makes it an essential component in the overall industrial automation setup. It seamlessly integrates into existing control systems, enhancing the efficiency and productivity of industrial processes.

Core advantages and technical highlights

Precision control: The FFVO142 3BSE223732R0001 is equipped with advanced control algorithms. These algorithms, combined with its current – regulation capabilities, enable it to achieve highly accurate rolling force adjustments. In metal rolling, for example, even the slightest deviation in rolling force can lead to defects in the final product. The precise control offered by this device helps in minimizing such defects, resulting in higher – quality output and reduced material waste.

High reliability: Built to withstand harsh industrial environments, the FFVO142 is designed with durability in mind. It can operate in conditions where there may be high temperatures, humidity, dust, and electrical interference. The robust construction and high – quality components ensure that the device maintains stable performance over an extended period, reducing the risk of unexpected downtime and maintenance costs.

Modular design: With a well – structured modular system, the FFVO142 offers ease of maintenance and component replacement. In case a particular module malfunctions, technicians can quickly identify and replace it without having to replace the entire device. This modular approach not only simplifies maintenance but also reduces the time required for repairs, keeping industrial operations running smoothly.

Comprehensive safety protection: Safety is a top priority in industrial settings, and the FFVO142 delivers on this front. It comes equipped with overcurrent, over – temperature, and other safety mechanisms. In the event of an overcurrent situation, the device can detect the anomaly and immediately shut down to prevent damage to itself and other connected equipment. Similarly, the over – temperature protection ensures that the device does not overheat, protecting its internal components from thermal stress and potential failure.

Versatile communication capabilities: The multiple communication interfaces, including Profibus and Modbus, allow the FFVO142 to integrate seamlessly with a wide variety of control systems. Whether it’s a new, state – of – the – art industrial network or an older, legacy control system, this device can communicate effectively. This versatility enables it to be part of complex industrial automation setups, where different devices need to communicate and coordinate with each other for efficient operation.

Typical application scenarios

Steel and metallurgy industry: In steel mills, the FFVO142 can be used in the rolling mills to control the rolling force precisely. When producing different grades of steel sheets or bars, the required rolling force varies. The device can adjust the rolling force in real – time according to the production requirements, ensuring that the steel products meet the strict quality standards. For example, in the production of high – strength steel for automotive applications, precise rolling force control is essential to achieve the desired mechanical properties.

Chemical industry: In chemical plants, there are often processes that involve the use of rollers for tasks such as film production or material extrusion. The FFVO142 can be used to control the rolling force in these processes. By ensuring consistent rolling force, it helps in producing uniform chemical products, such as plastic films with consistent thickness, which is crucial for their performance in applications like packaging.

Food processing industry: In food processing, the FFVO142 can find applications in equipment that uses rollers for tasks like dough rolling in bakeries or sheet – forming in the production of processed cheese. Precise control of the rolling force ensures that the food products are of consistent quality. For instance, in a bakery, the right rolling force is needed to make uniform sheets of dough for consistent baking results.

Power generation industry: In power plants, certain equipment may use rolling – based mechanisms for tasks such as conveyor belt tensioning or component alignment. The FFVO142 can be used to control the rolling – related forces in these applications. Its reliability and precision ensure that the power plant’s auxiliary systems operate smoothly, contributing to the overall stable operation of the power generation process.

ABB FFVO142 3BSE223732R0001

Comparison with related models in the series

Compared with ABB PFVO102: The PFVO102, while also being an industrial automation control device in the same general product family, may have different levels of performance and functionality compared to the FFVO142 3BSE223732R0001. The FFVO142 might offer a higher degree of precision in control, especially in rolling – force – sensitive applications. It could also have more advanced communication capabilities or better – suited for handling higher – power requirements in industrial processes. For example, if the PFVO102 has a limited speed range or less accurate control algorithms, the FFVO142 can be a better choice for applications that demand a wider speed range and more precise force control.

Compared with other brands’ similar products: ABB’s FFVO142 stands out due to ABB’s long – established reputation for quality and reliability. ABB has a vast global network of research and development, manufacturing, and technical support facilities. This means that customers can expect better – engineered products, longer – lasting performance, and more comprehensive technical support. Competing products may not offer the same level of integration with ABB’s extensive range of industrial products. ABB also invests heavily in research and development to continuously improve its products, ensuring that the FFVO142 incorporates the latest technological advancements in industrial control, giving it an edge over similar products from other brands.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the FFVO142 3BSE223732R0001, carefully assess the installation site. Ensure that the area is clean, dry, and free from excessive dust and moisture. Check the electrical supply to confirm that it falls within the specified input voltage range. Gather all the necessary installation tools, such as screwdrivers, wire strippers, and crimping tools. If the device is to be integrated into an existing control system, review the compatibility of the communication interfaces and the overall system architecture. Also, make sure that the power system in the installation area has been properly shut down and isolated to prevent any electrical accidents during installation.

Commissioning process: Once installed, connect the FFVO142 to the relevant control systems, power sources, and any other associated equipment according to the provided wiring diagrams. Double – check all connections to ensure they are secure and properly insulated. Power on the device and perform an initial self – test. Use the device’s built – in configuration tools or connected communication interfaces to set up the control parameters according to the specific requirements of the industrial application. For example, if it’s being used in a metal – rolling process, set the appropriate rolling – force control values. Test the device’s functionality by running some sample operations. Monitor the performance using appropriate testing equipment to ensure that the output voltage, current, and control functions are operating as expected. Also, verify the proper functioning of the safety protection features by simulating overcurrent and over – temperature scenarios (under controlled conditions) to ensure that the emergency shutdown mechanisms work correctly.

Maintenance suggestions: Regularly inspect the FFVO142 for any signs of physical damage, such as cracks in the housing or loose connections. Clean the device periodically using a dry, lint – free cloth to remove any dust that may have accumulated, as dust can affect the performance of the internal components. Check the communication status with other devices in the network at regular intervals to ensure seamless data transfer for control and monitoring purposes. Review the data logs (if available) to look for any patterns or signs of abnormal behavior in the device’s operation. If any issues are detected, refer to the troubleshooting section of the product manual. In case of more complex problems, contact ABB’s technical support team, who can provide remote or on – site assistance. Replace any worn – out or faulty components with genuine ABB parts to maintain the device’s performance and reliability.

Service and guarantee commitment

ABB offers a standard [warranty period] warranty for the FFVO142 3BSE223732R0001, covering any manufacturing defects. ABB’s global technical support team is available 24/7 to assist customers. They can provide remote support through online communication channels, guiding customers through installation, commissioning, and troubleshooting processes. In cases where on – site assistance is required, trained technicians can be dispatched to the customer’s location. ABB also regularly updates the product’s software and technical documentation to improve performance, add new features, and address any potential security vulnerabilities. This commitment to service and support ensures that customers can rely on the FFVO142 for long – term, reliable operation in their industrial applications.