Description

ABB FENA-11 Ethernet Communication Module – Technical Specifications

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB FENA-11 |

| Manufacturer | ABB |

| Product Category | Industrial Ethernet Communication Module |

| Interface Type | 10/100BASE-TX Ethernet (RJ45) |

| Protocol Support | Modbus TCP/IP, PROFINET IO, EtherNet/IP |

| Data Transfer Rate | 10/100 Mbps auto-negotiation |

| Isolation Voltage | 1500 VAC (field to logic) |

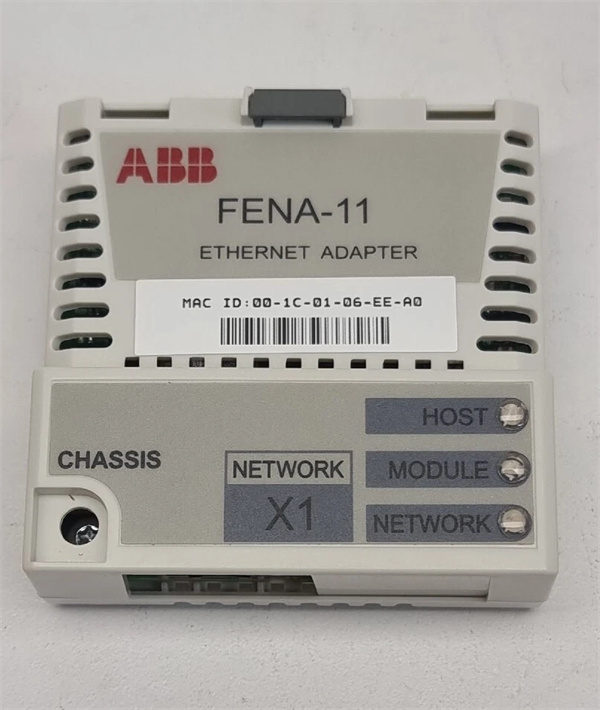

| LED Indicators | Power, Status, Link/Activity, Error |

| Power Supply | 24 VDC (via backplane) |

| Power Consumption | 2.8 W typical |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Vibration Resistance | 5g @ 10-150 Hz |

| Shock Resistance | 15g @ 11ms duration |

| Certifications | CE, UL, cULus, FCC Part 15 |

ABB FENA-11

Product Introduction

The ABB FENA-11 is a high-performance industrial Ethernet communication module designed for seamless integration of ABB’s AC500 PLC systems into modern networked automation environments. As part of ABB’s extensive communication portfolio, this rugged module bridges the gap between field devices and higher-level control systems with exceptional reliability.

Supporting multiple industrial Ethernet protocols simultaneously, including Modbus TCP/IP, PROFINET IO, and EtherNet/IP, the ABB FENA-11 enables real-time data exchange between PLCs, HMIs, SCADA systems, and enterprise networks. Its robust industrial design ensures reliable operation in harsh electrical environments commonly found in manufacturing plants and process industries.

The module serves as a critical component in distributed control architectures, providing deterministic communication for time-sensitive automation applications while maintaining compatibility with standard IT infrastructure. With its plug-and-play installation and intuitive configuration via ABB’s Automation Builder software, the ABB FENA-11 significantly reduces commissioning time compared to traditional communication solutions.

Core Advantages and Technical Highlights

Multi-protocol communication: The ABB FENA-11 stands out with its unique ability to support multiple industrial Ethernet protocols simultaneously. This protocol flexibility allows seamless integration with equipment from various manufacturers without requiring additional gateways or protocol converters. The module automatically handles protocol conversion, reducing engineering effort and potential points of failure in the network architecture.

Industrial-grade reliability: Designed for 24/7 operation in demanding environments, the ABB FENA-11 features enhanced protection against electrical noise, vibration, and extreme temperatures. Its 1500V isolation between field and logic circuits prevents ground loops and ensures stable communication even in electrically noisy installations. The robust metal housing provides excellent EMI/RFI immunity while effectively dissipating heat.

Advanced diagnostics and troubleshooting: Comprehensive diagnostic capabilities are built into the ABB FENA-11, including detailed status LEDs and extensive error logging. The module continuously monitors network health, providing early warning of potential issues before they impact system performance. Through ABB’s engineering tools, technicians can access detailed communication statistics, helping optimize network performance and quickly resolve connectivity issues.

Seamless system integration: The ABB FENA-11 integrates perfectly with ABB’s AC500 PLC platform, automatically appearing in the project hardware configuration. Its web server functionality allows remote monitoring and basic configuration via standard web browsers, while the integrated DHCP client simplifies network address assignment. The module supports LLDP (Link Layer Discovery Protocol) for automatic topology detection in PROFINET networks.

ABB FENA-11

Typical Application Scenarios

The ABB FENA-11 excels in various industrial automation scenarios:

Smart manufacturing systems: In Industry 4.0 implementations, the ABB FENA-11 enables seamless data exchange between production equipment and MES/ERP systems. Its support for OPC UA (when configured with appropriate software) allows secure vertical integration while maintaining separation between OT and IT networks.

Process control networks: For continuous process industries like oil & gas or chemical plants, the ABB FENA-11 provides reliable communication between distributed I/O and control systems. Its robust design withstands harsh environmental conditions while ensuring deterministic data transmission for critical control loops.

Machine automation: As a machine builder solution, the ABB FENA-11 offers flexible connectivity options to interface with various robot controllers, vision systems, and other intelligent devices. The module’s compact design saves valuable control cabinet space while its vibration resistance ensures reliable operation in high-motion environments.

Energy management systems: In power distribution applications, the ABB FENA-11 facilitates real-time monitoring of energy consumption across multiple substations. Its support for IEC 61850 (when properly configured) makes it suitable for smart grid applications requiring standardized communication protocols.

Related Model Recommendations

ABB FENA-12: Dual-port version with integrated switch functionality

ABB FI830: PROFIBUS DP communication module for legacy systems

ABB CI867: Advanced communication interface with OPC UA support

ABB CM572: PROFINET controller module for real-time applications

ABB TP830: DeviceNet communication module for fieldbus networks

ABB CP600: HMI panel for local visualization and control

ABB PM856: Redundant power supply for critical applications

ABB SD832: Serial communication module for legacy devices

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the ABB FENA-11, ensure the control cabinet environment meets specified temperature and humidity requirements. Verify proper grounding of the cabinet and availability of suitable Ethernet cabling (recommended: CAT5e or better with industrial-grade connectors). Prepare the network infrastructure including switches with appropriate industrial certifications.

Commissioning procedure: Mount the module on the DIN rail or backplane, ensuring proper seating in the base unit. Connect the Ethernet cable using strain relief fittings for vibration resistance. Power up the system and verify module recognition in Automation Builder. Configure network parameters either manually or via DHCP, then establish communication with target devices. Perform comprehensive network tests including ping tests and protocol-specific diagnostics.

Maintenance suggestions: Implement regular network health checks using the module’s diagnostic tools. Monitor error counters and network utilization statistics periodically. Keep firmware updated to the latest stable version, scheduling updates during planned maintenance windows. For troubleshooting, utilize the detailed status LEDs and web interface for quick diagnosis of common issues. Maintain proper documentation of network settings and device relationships.

Service and Guarantee Commitment

ABB provides comprehensive support for the ABB FENA-11, including:

Standard 36-month warranty covering materials and workmanship

Extended warranty options available for critical applications

Global technical support network with local language assistance

Lifetime product support commitment (minimum 10 years availability)

Firmware updates and security patches through ABB’s official channels

On-site engineering support for complex installations

Training programs for system integrators and end-users

The ABB FENA-11 is developed and manufactured under ABB’s stringent quality management system certified to ISO 9001. All modules undergo rigorous testing before shipment, including extended burn-in tests for reliability verification. ABB’s application engineers are available to assist with network design optimization and troubleshooting to ensure optimal performance of your ABB FENA-11 communication infrastructure.