Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DYTP123A 61430001-TW |

| Manufacturer | ABB |

| Product category | Terminal connection module |

| Rated voltage | 600 V AC/DC (max) |

| Rated current | 25 A per terminal |

| Number of terminals | 24 (12 input, 12 output) |

| Terminal type | Spring clamp (tool-free) |

| Wire size range | 0.5 – 2.5 mm² (solid/stranded) |

| Insulation material | Polyamide (PA66), flame-retardant (UL94 V-0) |

| Operating temperature | -40°C to 85°C |

| Dimensions | 100 mm × 60 mm × 30 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 60947-7-1, CE, UL, RoHS |

| Color coding | Inputs (blue), outputs (gray) for easy identification |

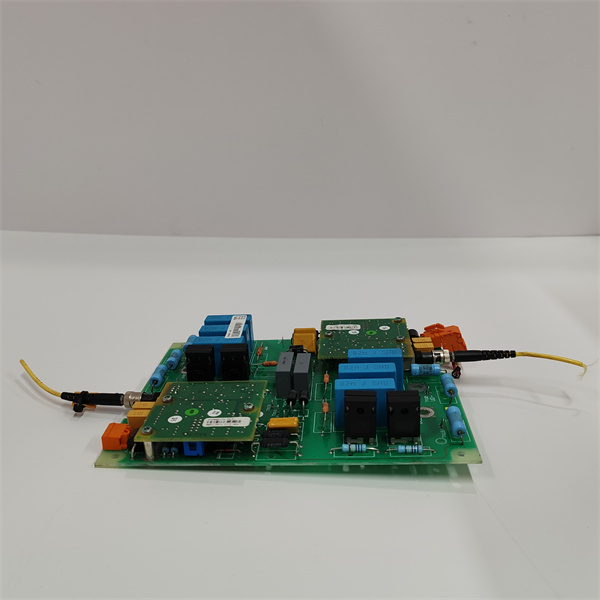

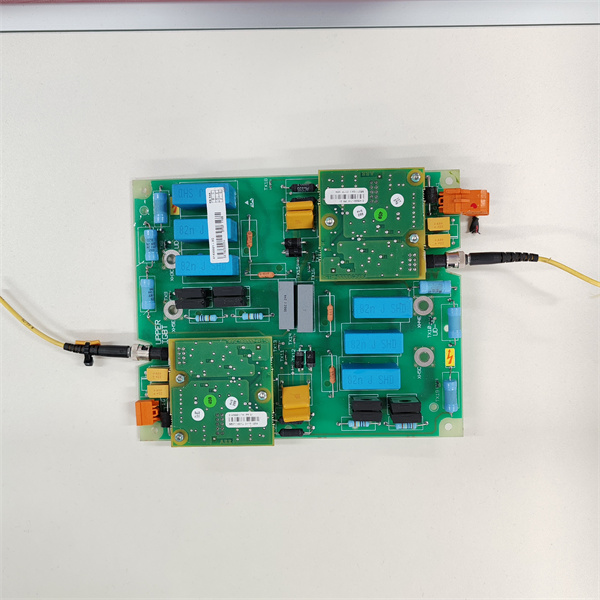

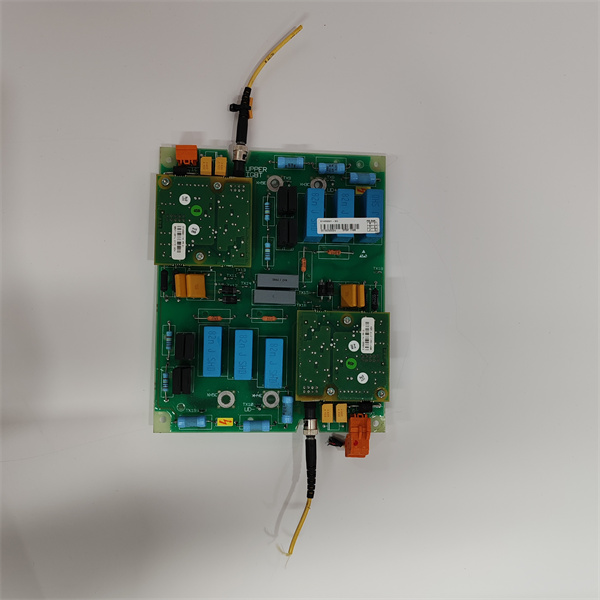

ABB DYTP123A 61430001-TW

Product introduction

The DYTP123A 61430001-TW is a compact terminal connection module from ABB, designed to simplify and secure wiring in industrial control systems. As a critical component in automation enclosures, this module serves as an interface between field devices (sensors, actuators) and control modules like the PCD235C101, streamlining installation and reducing wiring errors.

Unlike the PCD235C101, which focuses on control logic, the DYTP123A specializes in reliable electrical connections. Its tool-free spring clamp terminals eliminate the need for screwdrivers, speeding up wiring tasks while ensuring consistent clamping force—critical for vibration-prone environments like manufacturing floors. With color-coded inputs and outputs, it simplifies system debugging and maintenance, making it ideal for applications ranging from machine control panels to substation enclosures.

Core advantages and technical highlights

Key differences from PCD235C101 3BHE057901R0101

| Feature | PCD235C101 | DYTP123A |

| Primary function | Control logic and digital I/O processing | Electrical connection interface |

| Core component | 32-bit processor | Spring clamp terminals |

| Wiring method | Screw terminals (requires tools) | Tool-free spring clamps |

| Value proposition | Complex automation control | Simplified wiring, reliability |

| Integration role | Controls field devices | Connects field devices to controllers |

ABB DYTP123A 61430001-TW

Typical application scenarios

Machine control panel

In a CNC machine control panel, the DYTP123A connects limit switches (inputs) and servo motor drivers (outputs) to the PCD235C101. Its tool-free terminals allow quick replacement of damaged sensors during maintenance, while color coding ensures technicians correctly reconnect wires—critical for avoiding axis misalignment errors in precision machining.

Building automation

In a commercial HVAC control system, the module interfaces temperature sensors and damper actuators with a BMS controller. Its wide temperature range (-40°C to 85°C) ensures reliable operation in rooftop enclosures, while spring clamps simplify wiring during system expansions (e.g., adding new zone sensors).

Substation auxiliary systems

The DYTP123A connects battery backup systems and alarm contacts to protection relays in a power substation. Its flame-retardant housing and UL94 V-0 rating minimize fire risk in high-voltage environments, while tool-free terminals allow rapid reconfiguration during system upgrades.

Related model recommendations

ABB PCD235C101 3BHE057901R0101

The DYTP123A serves as the wiring interface for the PCD235C101, connecting field devices to the control module. Together, they form a complete “connection + control” solution in automation enclosures.

ABB TB857 surge protector

Installed upstream of the DYTP123A, this device shields terminals from voltage transients (e.g., lightning strikes), protecting sensitive control modules like the PCD235C101.

ABB MNS3.0 enclosure

A modular control cabinet that houses the DYTP123A and PCD235C101, with pre-cut DIN rail slots for easy installation. Its IP54 rating complements the module’s IP20 protection in dusty environments.

ABB CM-M12 adapter

Converts M12 circular connectors (used by sensors) to wire leads compatible with the DYTP123A, eliminating the need for custom cable assembly.

ABB ZB5 terminal marker set

Labels for terminal identification, enhancing traceability when multiple DYTP123A modules are used in large systems.

Installation, commissioning and maintenance instructions

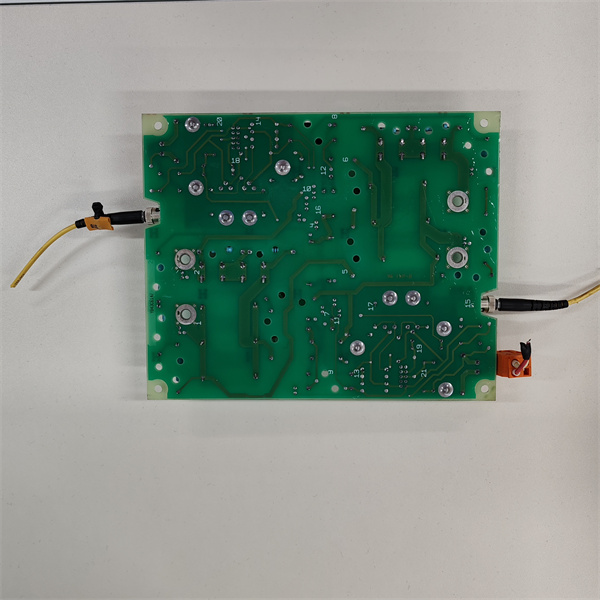

Installation: Mount the DYTP123A on a 35 mm DIN rail, leaving 10 mm clearance above/below for ventilation. Align input terminals (blue) with field device wiring and output terminals (gray) with control module connections (e.g., PCD235C101 inputs). Strip wires to 8 – 10 mm, press the orange lever to open the clamp, insert the wire, and release the lever—no tools required.

Commissioning: Verify wire insertion by gently tugging each conductor. Use a multimeter to check continuity between input terminals and connected sensors, ensuring no cross-wiring. For high-vibration environments, perform a pull test (max 5 N) to confirm wires remain secure.

Maintenance: Inspect quarterly for dust accumulation (use compressed air to clean). Check for terminal discoloration (indicates overheating) and re-tighten if necessary (via lever). Replace the module if terminals show signs of damage (e.g., cracks in the housing) or if wire retention force drops below 15 N (test with a force gauge).

Service and guarantee commitment

The DYTP123A 61430001-TW is backed by a 10-year warranty, covering manufacturing defects and ensuring compliance with IEC 60947-7-1 standards. ABB’s technical support provides wiring guidelines and compatibility checks with control modules like the PCD235C101.

Extended service includes access to 3D CAD models for enclosure design and bulk packaging options for large-scale projects. ABB guarantees RoHS compliance, ensuring the module meets global environmental regulations for lead-free manufacturing. This commitment reflects its role as a durable, long-lasting component in industrial wiring systems.