Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DYSF118B 61430001-XG |

| Manufacturer | ABB |

| Product category | Terminal connection module |

| Rated voltage | 1000 V AC/DC (max) |

| Rated current | 40 A per terminal |

| Number of terminals | 18 (9 input, 9 output) |

| Terminal type | Screw clamp (with torque control) |

| Wire size range | 1.5 – 6 mm² (solid/stranded) |

| Insulation material | Polyester (PET), flame-retardant (UL94 V-0) |

| Operating temperature | -30°C to 90°C |

| Dimensions | 120 mm × 70 mm × 35 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 60947-7-1, CE, UL, RoHS |

| Color coding | Inputs (red), outputs (black) for easy identification |

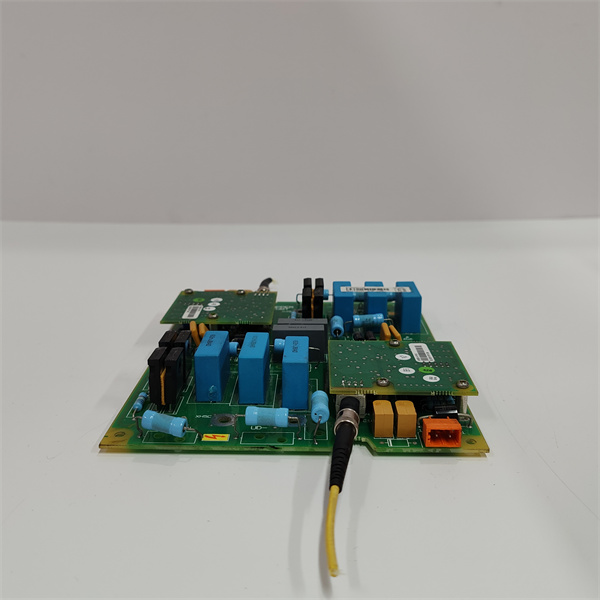

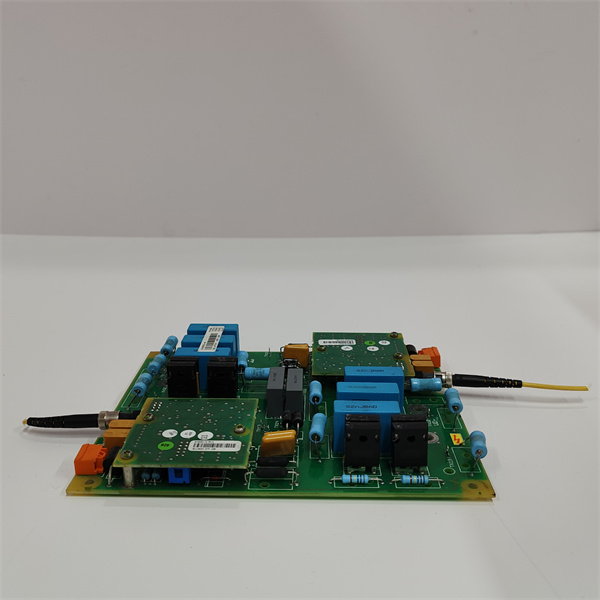

ABB DYSF118B 61430001-XG

Product introduction

The DYSF118B 61430001-XG is a heavy-duty terminal connection module from ABB, engineered to handle higher current and voltage requirements in industrial control systems. As a robust alternative to the DYTP123A, this module is designed for applications where larger wire sizes and secure, torque-controlled connections are essential—such as power distribution panels, motor control centers, and high-power industrial machinery.

While sharing the core function of simplifying wiring connections with the DYTP123A, the DYSF118B distinguishes itself with screw clamp terminals that provide precise torque control, making it ideal for high-vibration environments where connection integrity is critical. Its higher current and voltage ratings enable it to serve as a bridge between heavy-duty field devices (e.g., large motors, contactors) and control modules like the PCD235C101, ensuring reliable power transmission and signal integrity in demanding industrial settings.

Core advantages and technical highlights

High-power handling capability

With a rated current of 40 A per terminal (vs. 25 A in the DYTP123A) and a maximum voltage of 1000 V AC/DC (vs. 600 V), the DYSF118B is built to manage heavy-duty electrical loads. This makes it suitable for connecting large motors, heating elements, and power distribution components. In a steel mill’s motor control center, for example, it can reliably handle the high currents from 50 HP motor starters, ensuring stable power delivery without overheating.

Torque-controlled screw terminals

Unlike the tool-free spring clamps of the DYTP123A, the DYSF118B features screw terminals with a specified torque range (0.8 – 1.2 Nm). This allows for precise, repeatable connections, critical in applications where vibration or thermal cycling could loosen connections. In a reciprocating compressor system, the controlled torque ensures that power leads to the compressor motor remain secure, preventing arcing and potential equipment damage.

Accommodates larger wire sizes

The module supports wire sizes from 1.5 to 6 mm², significantly larger than the DYTP123A’s 0.5 – 2.5 mm² range. This enables direct connection to heavy-gauge power cables without the need for adapters. In a solar farm’s inverter station, it can connect 6 mm² DC cables from solar panels to the inverter, eliminating junction points that could introduce resistance or failure risks.

Enhanced thermal resistance

Constructed from polyester (PET) insulation material, the DYSF118B withstands higher operating temperatures (up to 90°C) compared to the DYTP123A’s 85°C. Its material composition also offers superior resistance to oils, solvents, and industrial chemicals, making it suitable for use in automotive manufacturing plants or chemical processing facilities where exposure to such substances is common.

Key differences from DYTP123A 61430001-TW

| Feature | DYTP123A | DYSF118B |

| Rated current | 25 A per terminal | 40 A per terminal |

| Max voltage | 600 V AC/DC | 1000 V AC/DC |

| Terminal type | Tool-free spring clamp | Torque-controlled screw clamp |

| Wire size range | 0.5 – 2.5 mm² | 1.5 – 6 mm² |

| Number of terminals | 24 (12 input, 12 output) | 18 (9 input, 9 output) |

| Operating temperature range | -40°C to 85°C | -30°C to 90°C |

| Insulation material | Polyamide (PA66) | Polyester (PET) |

| Color coding | Inputs (blue), outputs (gray) | Inputs (red), outputs (black) |

ABB DYSF118B 61430001-XG

Typical application scenarios

Motor control centers

In an industrial motor control center, the DYSF118B connects 40 A contactors to overload relays and power cables. Its screw terminals, tightened to the specified torque, ensure secure connections even during motor startup surges. The red/black color coding helps technicians quickly identify power inputs and motor outputs, reducing wiring errors during maintenance.

Power distribution panels

In a commercial building’s main distribution panel, the module links circuit breakers to busbars and branch circuits. Its 1000 V rating allows it to handle the building’s 480 V three-phase power, while the 6 mm² wire capacity accommodates the thick cables feeding high-power equipment like HVAC compressors and elevator motors.

Renewable energy systems

In a wind turbine’s control cabinet, the DYSF118B connects the generator’s output cables to the power converter. Its resistance to vibration (via torque-controlled screws) and high temperature tolerance ensure reliable operation in the turbine’s nacelle, where temperatures can reach 85°C during peak operation.

Related model recommendations

ABB PCD235C101 3BHE057901R0101

The DYSF118B serves as the high-power connection interface for the PCD235C101, linking the control module to heavy-duty actuators and power devices. Together, they form a robust control and connection system for high-current applications.

ABB TB857 surge protector

Installed upstream of the DYSF118B, this device protects against voltage transients in high-power circuits, safeguarding both the module and connected control equipment like the PCD235C101.

ABB MNS-XS enclosure

A heavy-duty control cabinet designed to house the DYSF118B and associated high-power components. Its reinforced structure and IP55 rating provide protection in harsh industrial environments.

ABB SKM100GB12T4 IGBT module

When paired with the DYSF118B, this power semiconductor module enables precise control of high-current motors, with the DYSF118B managing the power connections.

ABB ZB5 terminal marker set

Labels for terminal identification, essential when multiple DYSF118B modules are used in large power distribution systems to ensure traceability.

Installation, commissioning and maintenance instructions

Installation: Mount the DYSF118B on a 35 mm DIN rail, ensuring 15 mm clearance above and below for heat dissipation. Connect input terminals (red) to power sources or field devices, and output terminals (black) to control modules or load devices. Strip wires to 10 – 12 mm, insert into terminals, and tighten screws to 0.8 – 1.2 Nm using a torque screwdriver. Use 1.5 – 6 mm² stranded or solid wire, ensuring no stray strands are exposed.

Commissioning: After installation, verify torque settings on all terminals using a calibrated torque screwdriver. Check continuity between connected devices using a multimeter to ensure proper wiring. Perform a high-voltage insulation test (up to 1000 V) to confirm insulation integrity between terminals and ground.

Maintenance: Inspect the module semi-annually for signs of overheating (discoloration) or loose connections. Re-tighten terminals to the specified torque if necessary. Clean dust and debris using a soft brush or compressed air. Replace the module if terminals show signs of corrosion, cracking, or excessive wear. In high-vibration environments, check torque quarterly to prevent loosening.

Service and guarantee commitment

The DYSF118B 61430001-XG is backed by a 10-year warranty, covering manufacturing defects and ensuring compliance with IEC 60947-7-1 standards. ABB’s technical support provides guidance on proper installation, including torque specifications and wire selection, to ensure optimal performance.

Extended service includes access to detailed installation guides, 3D CAD models for enclosure design, and bulk packaging options for large-scale projects. ABB guarantees that the module meets RoHS and REACH environmental standards, making it suitable for use in global industrial applications. This commitment underscores the DYSF118B’s role as a reliable, long-lasting solution for high-power terminal connections.