Description

Key Technical Specifications

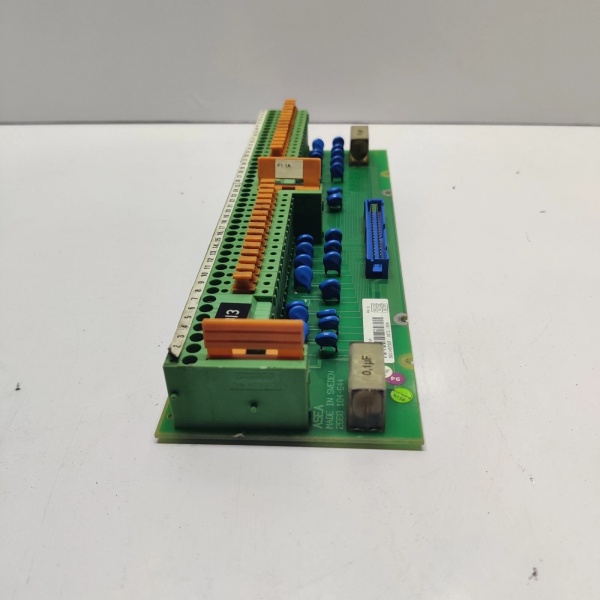

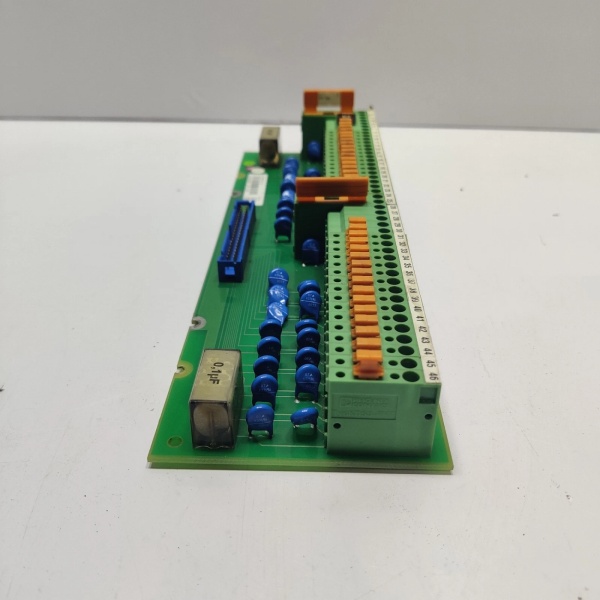

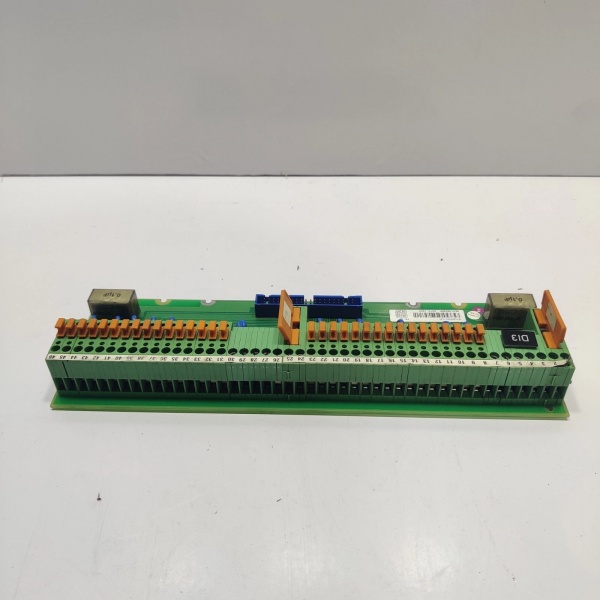

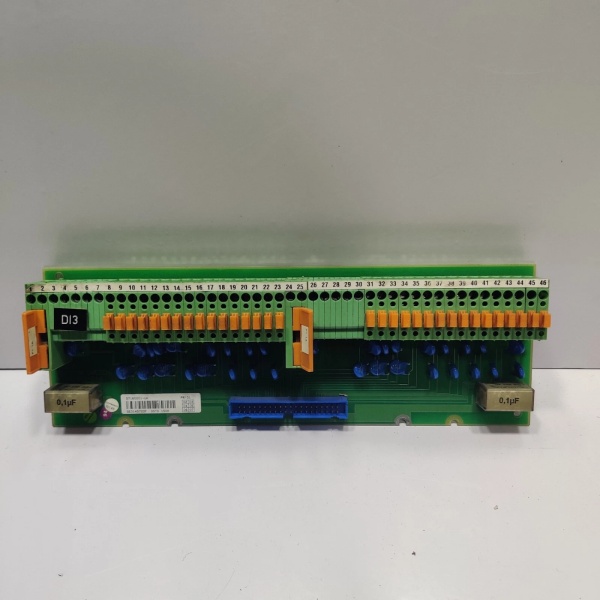

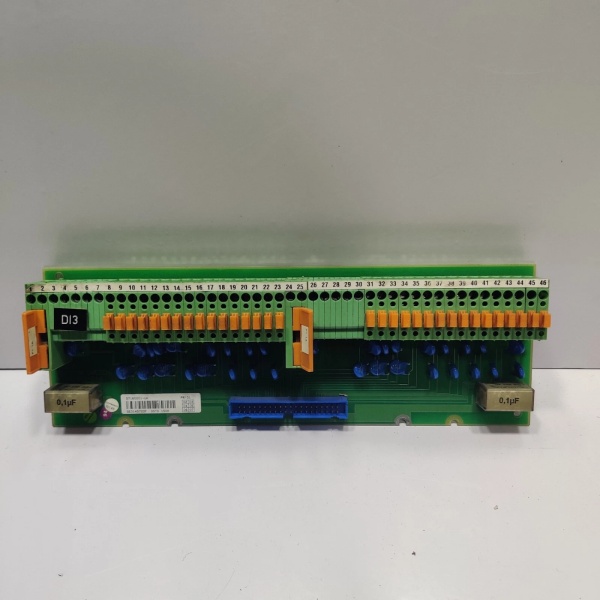

- Model Number: DSTD150A

- Manufacturer: ABB Power Automation

- Input Channels: 16 independent 24VDC digital input channels (sink/source configurable)

- Response Time: 1ms max (for signal state change detection and backplane transmission)

- Input Voltage Range: 18–30VDC (nominal 24VDC)

- Input Current: 6mA per active channel

- Isolation Rating: 500V AC (channel-to-channel; channel-to-backplane)

- Backplane Compatibility: Symphony Plus I/O rack backplane (supports redundant bus configuration)

- Power Supply: 24VDC ±10% (from rack power supply; 0.3A max current draw)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP20 (rack-mounted, indoor control cabinet use)

- Certifications: UL 508, CE, IEC 61508 (SIL 2 compliant), IEEE 1613 (power utility certified)

ABB DSTD150A

Field Application & Problem Solved

In power generation and heavy industrial facilities, the biggest challenge with discrete input acquisition is speed and reliability for protective loops. Legacy DI modules with 10ms+ response times can’t keep up with turbine or boiler protection systems—by the time a “high vibration” or “low oil pressure” signal reaches the DCS, the equipment is already at risk of damage. A Southeast Asian combined-cycle power plant once suffered a turbine bearing failure because a slow DI module delayed the trip signal by 12ms, costing $2M in repairs and downtime.

The DSTD150A solves this with its 1ms response time, making it the go-to module for protective and safety-critical loops in Symphony Plus systems. You’ll find it in gas turbine control rooms monitoring vibration switch contacts, in boiler houses detecting flame presence, and in pulp mills tracking emergency stop button status. Its core value is high-speed signal detection paired with redundant backplane support: if the primary communication bus fails, the module switches to the standby bus in <5ms, ensuring trip signals never get lost. At a Midwest coal-fired power plant, this module cut turbine protection loop response time by 90%, eliminating false trips and ensuring legitimate faults trigger shutdowns in time.

Another hidden value is its sink/source configurability. Unlike fixed-input modules, the DSTD150A works with both PNP and NPN sensors, reducing spare parts inventory by 50%—a critical win for remote power plants with limited storage space. Its 500V isolation also blocks electrical noise from motor drives and high-voltage switchgear, eliminating false alarms caused by EMI in turbine halls.

Installation & Maintenance Pitfalls (Expert Tips)

Sink/Source Configuration Must Match Sensor Type: Rookies leave all channels set to default sink mode and connect PNP sensors, resulting in “no signal” faults. The DSTD150A’s configuration is done via Symphony Plus Control Builder—group channels by sensor type (sink = NPN, source = PNP) and verify settings before powering on. A 10-minute check of the I/O list prevented a 4-hour outage at a pulp mill, where 8 channels were misconfigured for flame detectors.

Terminal Torque = 0.5 N·m (No Exceptions): Under-tightening terminals causes intermittent signal drops in high-vibration environments (e.g., near turbines); over-tightening strips threads or damages wire insulation. Use a calibrated torque screwdriver—0.5 N·m is the sweet spot for 1.5mm² control wires. Recheck torque every 6 months in turbine halls; this fixed “random” emergency stop faults at a gas power plant.

Redundant Backplane Cables Require Separate Routing: Technicians run both primary and standby backplane cables through the same cable tray, defeating redundancy. If the tray is damaged (e.g., by maintenance equipment), both buses fail. Route cables through separate trays—ideally on opposite sides of the control room. A Texas power plant avoided a boiler shutdown when a forklift damaged a cable tray; the module switched to the standby bus instantly.

LED Diagnostics Are Your First Troubleshooting Tool: Rookies skip checking front-panel LEDs and jump straight to laptop diagnostics. Each channel has a dedicated LED—lit = signal active, unlit = no signal. A “dark” LED on a trip contact means either the sensor is faulty or the wire is broken; a lit LED with no DCS signal means a backplane communication fault. This simple check cut troubleshooting time by 70% at a cement plant.

ABB DSTD150A

Technical Deep Dive & Overview

The ABB DSTD150A is a microprocessor-driven digital input module engineered for safety-critical applications in Symphony Plus DCS. At its core, a 16-bit microcontroller monitors each of the 16 channels, using high-speed optocouplers to detect signal state changes in 1ms—far faster than legacy modules that rely on software polling. The optocouplers also provide 500V AC galvanic isolation, blocking ground loops and EMI that cause false alarms in harsh industrial environments.

The module’s redundant backplane support is enabled by dual communication ports, each connected to a separate Symphony Plus bus. A dedicated fault-detection circuit monitors bus health—if the primary bus loses communication, the module switches to the standby bus in <5ms, with no loss of signal data. This is critical for protective loops, where even a 10ms delay can lead to equipment damage.

Unlike generic DI modules, the DSTD150A stores channel status data in a buffer, transmitting updates to the DCS only when a state change occurs—this reduces backplane traffic by 80% and lowers CPU scan time. Front-panel LEDs provide real-time channel status, eliminating the need for a laptop to diagnose faulty sensors in remote locations. Built with conformal-coated circuit boards to resist dust and moisture, the module is rated for 15+ years of operation in power plant environments—making it a workhorse for turbine, boiler, and auxiliary system control.