Description

Key Technical Specifications

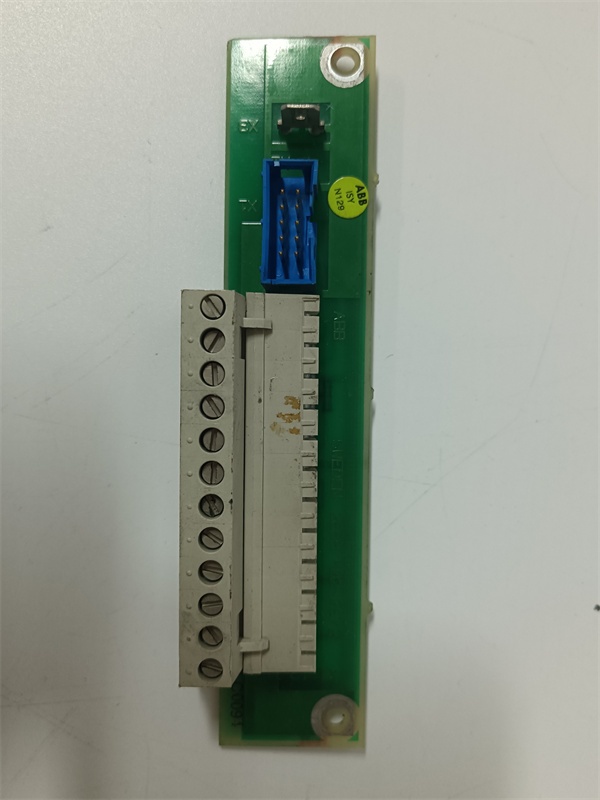

- Model Number: ABB DSTC175

- Manufacturer: ABB

- Input Type: Universal (RTD: Pt100/Pt1000; Thermocouple: K/J/T/E), channel-independent configuration

- Number of Input Channels: 8 (individually isolated)

- Output Signals: 2 x 4-20mA analog outputs (load ≤500Ω, configurable for control/alarm)

- Measurement Range: -50°C to +600°C (RTD); -200°C to +1300°C (thermocouple)

- Measurement Accuracy: ±0.1°C (0°C to 100°C); ±0.2°C (+100°C to +600°C)

- Operating Temperature: -25°C to +70°C (-13°F to 158°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Isolation: 250V AC (channel-to-channel); 500V AC (input-to-output/backplane, 1-minute withstand)

- Response Time: ≤200ms (for 1°C temperature change)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 1.2W (standby), 2.0W (full load)

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

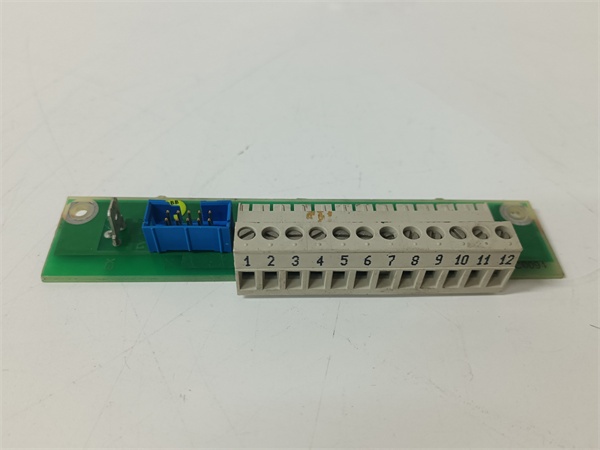

- Connector Type: Spring-cage terminal block (accepts 0.5-2.5mm² wire)

- Safety Certification: SIL 2 (IEC 61508), CE, UL

ABB DSTC175

Field Application & Problem Solved

In industrial processes—refineries, chemical reactors, and food processing lines—accurate temperature monitoring is non-negotiable for safety, quality, and efficiency. The challenge? Most temperature modules lock users into a single sensor type (either RTD or thermocouple), requiring multiple modules for mixed-sensor setups. Others lack sufficient isolation, leading to noise-induced inaccuracies in harsh electromagnetic environments, or fail to provide actionable diagnostics—leaving technicians unaware of broken sensor wires until a process drifts out of spec. The module solves these pain points with configurable channels, robust isolation, and built-in fault detection.

You’ll typically find this module in applications like monitoring reactor wall temperatures via K-type thermocouples in chemical plants, tracking steam line temperatures with Pt100 RTDs in power plants, or controlling oven temperatures in food processing facilities. It’s a critical component in AC 800M-based systems, where it consolidates 8 temperature inputs into a single slot—reducing rack space and wiring complexity. In pulp and paper mills, it’s used to monitor dryer cylinder temperatures, relying on its fast response time to prevent overheating and material waste. It also excels in SIL 2-rated safety loops (e.g., pressure vessel temperature monitoring), where its compliance with IEC 61508 ensures adherence to safety standards.

Its core value is flexibility and reliability in critical environments. The ability to mix RTD and thermocouple inputs eliminates the need for specialized modules, simplifying inventory and installation. Channel isolation blocks noise from motors, transformers, and high-voltage equipment—common in refineries and power plants—ensuring consistent accuracy. Built-in diagnostics (open circuit, short circuit) and dual 4-20mA outputs (for direct control or alarms) enable proactive maintenance and fast fault response. For operators, this means tighter process control, fewer unplanned shutdowns, and compliance with safety regulations—critical in industries where temperature deviations can lead to product loss or safety hazards.

Installation & Maintenance Pitfalls (Expert Tips)

- Thermocouple Cold Junction Compensation (Skipping = Major Errors): Thermocouples require cold junction compensation (CJC) to account for ambient temperature at the module’s terminals, but rookies often disable this feature or use incorrect ambient settings. This leads to temperature errors of ±10°C or more—catastrophic in precision processes. Ensure CJC is enabled in Control Builder M, and verify the module’s ambient sensor is not blocked by wiring or debris. For critical applications, cross-reference readings with a handheld thermocouple calibrator to confirm accuracy.

- RTD Lead Wire Length (Ignoring Resistance = Offset Errors): For 2-wire RTDs, rookies often use long lead wires without accounting for lead resistance. Each meter of 22 AWG wire adds ~0.5Ω, which the module interprets as a temperature increase (e.g., 1Ω = ~2.5°C for Pt100). Use 3-wire or 4-wire RTD configurations for runs over 10 meters—these compensate for lead resistance. If 2-wire is unavoidable, use 18 AWG wire to minimize resistance and enter the lead resistance value into the module’s configuration to offset errors.

- Terminal Wiring Tension (Over-Tightening = Terminal Damage): The module’s spring-cage terminals are tool-less, but rookies often over-tighten wires to “ensure a good connection.” Excessive force damages the terminal’s spring mechanism, leading to intermittent connections or permanent terminal failure. Insert wires fully until they click, then gently tug to verify retention—no additional force is needed. Use stranded wire with ferrules to prevent wire fraying, which can cause short circuits between terminals.

- Output Configuration Mismatch (Control vs. Alarm): The dual 4-20mA outputs are configurable for control signals or alarm triggers, but rookies often set them to the wrong mode. For example, using an alarm-configured output to drive a control valve results in on/off behavior instead of proportional control. Clearly define output purposes during configuration: use one output for closed-loop temperature control (proportional to measured temperature) and the other for high/low temperature alarms (setpoint-triggered). Test outputs with a multimeter before commissioning to confirm they respond as expected.

ABB DSTC175

Technical Deep Dive & Overview

The ABB DSTC175 is an 8-channel universal temperature input module designed for seamless integration with ABB’s AC 800M controller series. It functions as a front-end interface between temperature sensors (RTDs/thermocouples) and the controller’s CPU, converting physical temperature into digital values for processing and control. Its core design centers on channel independence—each of the 8 inputs can be individually configured for RTD or thermocouple, with software-selectable ranges and filter settings.

The module uses high-precision analog-to-digital (A/D) converters (24-bit resolution) to convert sensor signals into digital data, with built-in linearization for thermocouples and RTDs to compensate for non-linear sensor characteristics. Thermocouple inputs include cold junction compensation (CJC) via an internal ambient temperature sensor, eliminating the need for external ice baths or compensation circuits. RTD inputs support 2-wire, 3-wire, and 4-wire configurations, with automatic lead resistance compensation for 3/4-wire setups.

Communication with the AC 800M CPU occurs via the rack’s backplane bus, with data transmitted in real time (up to 10Hz per channel) to support fast control loops. The module’s dual 4-20mA outputs are driven by 16-bit digital-to-analog (D/A) converters, providing precise control signals for actuators (e.g., heating elements, cooling valves) or alarm triggers for SCADA systems.

Isolation is a key design feature: each input channel is isolated from the others and the backplane, preventing ground loops and fault propagation. The 500V AC input-to-output isolation protects the controller from high-voltage transients common in industrial environments. The module’s SIL 2 compliance (IEC 61508) is achieved through redundant internal circuitry and fault detection logic, making it suitable for safety-related applications.

Built for ruggedness, the DSTC175 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C), ideal for harsh industrial settings. Its compact 1-slot design maximizes I/O density, and hot-swappable capability (with compatible racks) allows replacement without shutting down the control system. The module’s non-volatile memory retains configuration settings during power loss, ensuring consistent operation after restart.