Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

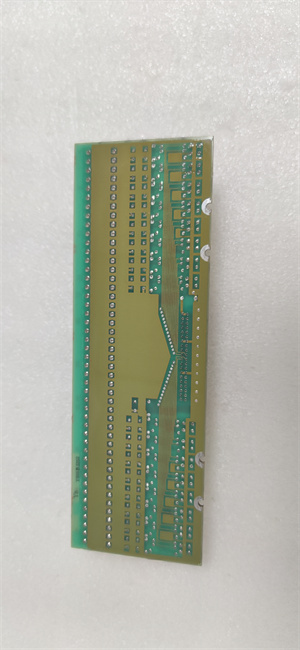

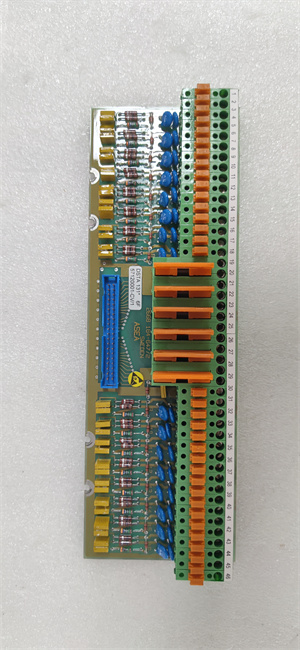

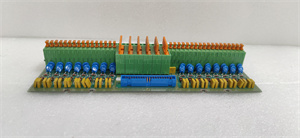

| Product Model | DSTA131 |

| Manufacturer | ABB |

| Product Category | Test Connector / Relay Test Block |

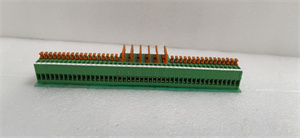

| Terminal Configuration | 31 test terminals + 1 grounding terminal |

| Rated Insulation Voltage | 750 V AC/DC |

| Dielectric Strength | 4 kV AC (50 Hz, 1 min) |

| Contact Resistance | ≤ 1.5 mΩ per pole |

| Wire Cross-Section | 0.5–6 mm² (AWG 20–10) |

| Operating Temperature | -40°C to +75°C |

| Housing Material | Fiberglass-reinforced PBT (UL94 V-0) |

| Mounting | DIN Rail (35 mm) |

| Safety Standards | IEC 61010-1, UL 1059, CAT III 1000V |

| Protection Rating | IP40 (front) / IP20 (rear) |

| Finger Protection | IP2X compliant |

ABB DSTA131

Product Introduction

The ABB DSTA131 is a high-density test connector engineered for comprehensive testing of protection relays and control systems in electrical substations and industrial power networks. As part of ABB’s Relion® testing ecosystem, this 31-pole test block enables technicians to safely access critical signals – including current transformer (CT) circuits, voltage transformer (VT) inputs, binary I/O, and communication ports – without disconnecting permanent wiring. The DSTA131 integrates seamlessly with Relion® 615/650/670 series protection relays, providing standardized test points for primary injection testing, functional verification, and diagnostic monitoring.

Featuring gold-plated contacts and reinforced isolation barriers, the ABB DSTA131 ensures measurement accuracy while preventing accidental contact with live circuits during testing procedures. Its color-coded terminals and modular labeling system streamline complex testing workflows in compliance with IEC 61850 engineering standards. By eliminating the need for physical wire disconnection, the ABB DSTA131 reduces commissioning time by up to 60% while maintaining the integrity of critical protection system wiring.

Core Advantages and Technical Highlights

Enhanced Electrical Safety:

4 kV dielectric strength and CAT III 1000V rating provide protection against arc flash hazards during live testing. Integrated test probe guidance channels prevent accidental short-circuits.

Measurement Precision:

Gold-over-nickel contacts maintain ≤1.5 mΩ resistance for accurate secondary injection testing. Dedicated CT shorting terminals prevent open-circuit hazards during relay maintenance.

Operational Efficiency:

Pre-wired test plugs (e.g., RTSD-31) enable simultaneous connection of multiple test instruments. Integrated test enable switch safely isolates relays from live process signals during calibration.

Durability in Extreme Conditions:

Fiberglass-reinforced housing withstands mechanical impact (IK08) and chemical exposure (fuels, lubricants). Operating range covers arctic (-40°C) to desert (+75°C) environments.

Cybersecurity Compliance:

Physical key lock option prevents unauthorized access to test ports in NERC CIP-regulated facilities. Audit trail compatible with test record management systems.

Typical Application Scenarios

Distance Protection Testing: Validates REL670 relay zones using primary injection sets connected via DSTA131 CT/VT terminals during substation commissioning.

Grid Stability Analysis: Monitors synchrophasor measurements (PMU data) through dedicated test ports without disrupting operational protection schemes.

Industrial Motor Protection: Executes timed overcurrent tests on RET615 relays controlling 10kV motors in cement plants using short-circuitable CT inputs.

Railway Traction Systems: Tests REG670 feeder protection in 25kV AC systems using integrated voltage shorting bars for catenary isolation.

Renewable Energy Plants: Performs routine calibration of REB500 busbar relays in solar farms without de-energizing inverters.

ABB DSTA131

Related Model Recommendations

RTSD-31: 31-pole test plug for full-access testing with DSTA131.

DSTA190: 19-pole variant for applications requiring fewer test points.

REF615: Feeder protection relay commonly interfaced with DSTA131.

RTIM600: Test interface module converting DSTA131 signals to OPC UA.

CMC356: Advanced relay test set with automatic DSTA131 recognition.

SHC200: Insulated test probe kit for spot measurements.

RER670: Generator protection relay tested via DSTA131 analog inputs.

REC650: Bay controller supporting DSTA131 diagnostic monitoring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Mount on 35mm DIN rail with end stoppers. Verify clearance (≥50mm above/below) for test probe access. Label terminals per relay schematic before wiring. Apply 0.6 N·m torque to screw terminals using calibrated torque screwdriver. Isolate all connected circuits before installation.

Maintenance Protocol:

Perform annual contact resistance verification using micro-ohmmeter. Clean terminals with non-residue electronic cleaner. Inspect after fault events for thermal damage. Verify dielectric strength every 5 years. Replace if insulation resistance drops below 100 MΩ at 1kV DC. Always use ABB-approved test plugs to prevent socket wear.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the DSTA131, covering material defects and performance deviations. Global support includes:

24/7 technical assistance for test configuration

On-site calibration verification at certified service centers

Complimentary wiring template generation for relay models

Lifetime firmware updates for compatible test systems

Extended service agreements offer:

Priority replacement with 8-hour emergency dispatch

Cybersecurity compliance audits for test interfaces

Training programs at ABB University covering ANSI/IEEE C37.90 test methodologies

All modules undergo dielectric testing at 150% rated voltage before shipment.