Description

Key Technical Specifications

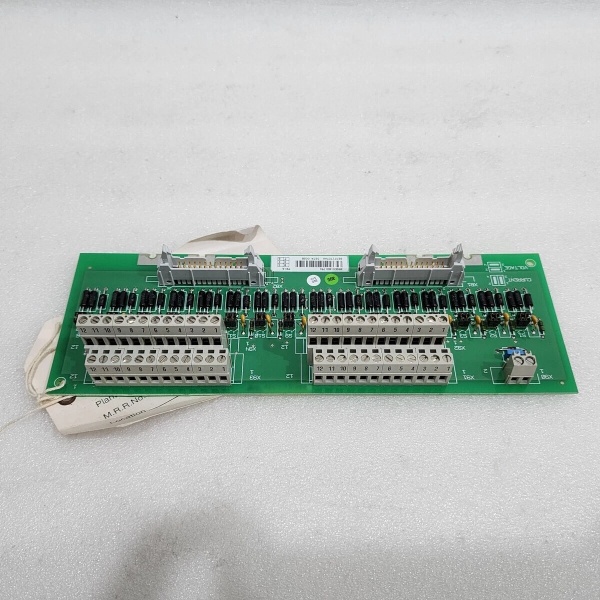

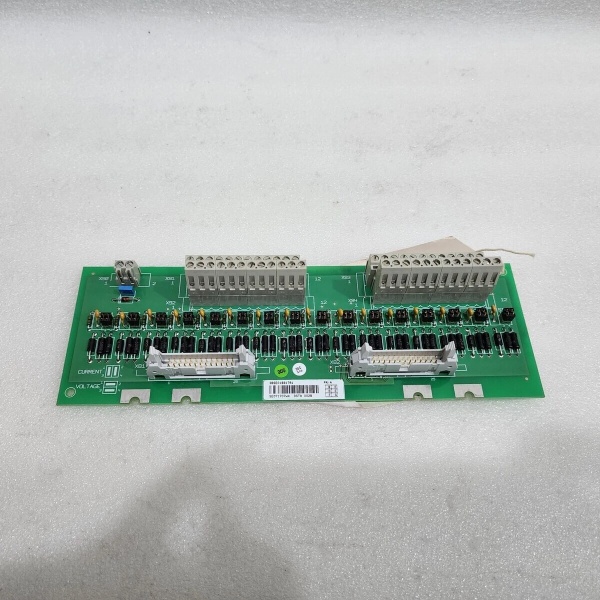

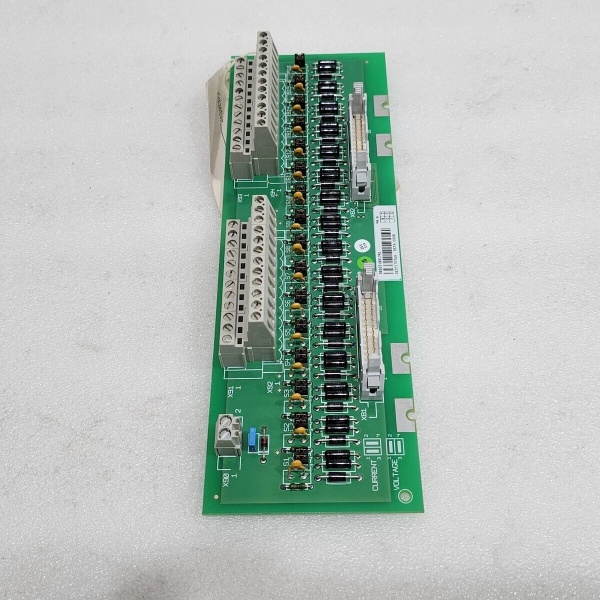

- Model Number: ABB DSTA002B 3BSE018317R1

- Manufacturer: ABB Industrial Automation Division

- Channel Configuration: 16 independent, software-configurable channels

- Input Type: 24VDC discrete (sinking or sourcing, selectable per channel)

- Input Voltage Range: 18-30VDC (on-state); <5VDC (off-state)

- Response Time: <5ms (90% of input transition)

- Isolation Rating: 500V AC (channel-to-channel); 1kV AC (inputs to backplane)

- Power Supply: 24VDC from DCS backplane; 0.15A typical current draw

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Certifications: IEC 61010-1, CE, UL 508, ATEX Zone 2, RoHS 2.0

- Compatibility: ABB AC800M controllers (PM860/PM861/PM864), Advant OCS racks, Control Builder M

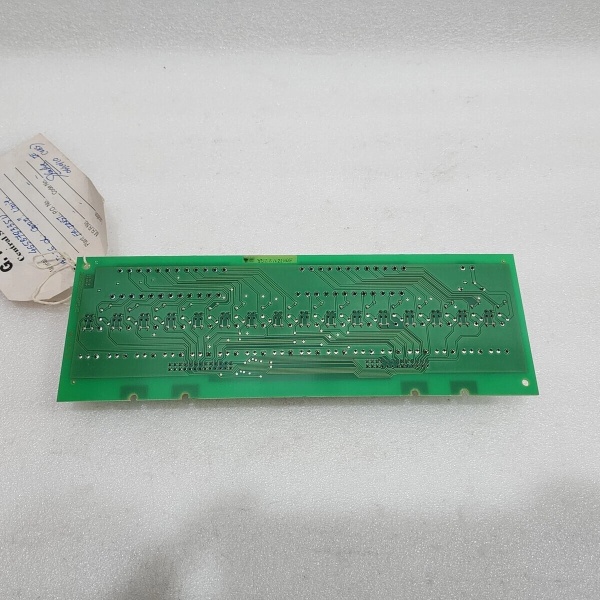

- Mechanical Design: Rack-mount (3U height), conformal-coated PCB, metal housing (IP20)

- Input Current: 5-10mA (on-state); <1mA (off-state)

ABB DSTA002B 3BSE018317R1

Field Application & Problem Solved

In process automation—refineries, chemical batch plants, power plant auxiliary systems—digital status inputs are critical for tracking equipment health, but generic modules fail due to cross-talk and poor DCS integration. A Louisiana refinery lost $80k in a 3-hour outage when a generic module’s lack of channel isolation caused false “valve closed” signals, triggering an emergency shutdown of a distillation unit. Legacy modules also force re-wiring for input type changes: a Wisconsin paper mill spent 4 hours reconfiguring hardware jumpers on generic modules when switching from sinking to sourcing sensors, costing 2 hours of production downtime.

You’ll find this module in AC800M DCS racks monitoring discrete devices: valve position feedback in Texas petrochemical plants, pump run/stop status in Ohio coal plants, and safety interlock contacts in Minnesota chemical facilities. Its core value is flexible, isolated input handling + ABB-native reliability. The channel-to-channel isolation eliminated the Louisiana refinery’s false signals—zero shutdowns from cross-talk in 4 years. At the paper mill, software-configurable input types (no hardware jumpers) cut reconfiguration time to 15 minutes, eliminating production delays.

For a Florida wastewater treatment plant, the module’s conformal coating withstood corrosive chlorine vapors, outlasting uncoated generic modules by 3x (6 years vs. 2 years). Its wide input voltage range also proved resilient during plant voltage sags, maintaining reliable readings when other modules dropped out.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Type Configuration: Match Sensor Polarity: Rookies set channels to sinking but connect sourcing sensors (or vice versa), resulting in no status detection. A North Carolina chemical plant delayed reactor startup by 3 hours due to this mistake. Use Control Builder M to select sinking (current flows into module) or sourcing (current flows out of module) per channel, and test with a multimeter: verify 24VDC at the input terminal when the sensor is active (on-state).

- Shielded Cable for Long Runs: Unshielded wiring picks up EMI from motors/VFDs, causing intermittent false inputs. A Michigan paper mill’s 25m valve feedback run had random “open” signals until we replaced unshielded wire with ABB’s 1SFL500001R0001 shielded cable. Ground the shield at the module end only—daisy-chaining grounds creates noise loops.

- Overloading Input Circuits: Using 24VDC power supplies with >30VDC output damages the module’s input circuits. A Colorado refinery used a 28VDC supply (exceeding the 30VDC max) and fried 4 channels ($200 in repairs). Use a regulated 24VDC supply (±10% tolerance) and install 30VDC zener diodes for surge protection in harsh electrical environments.

- Firmware Mismatch Breaks DCS Communication: Outdated module firmware (pre-v5.3) with AC800M v6.0+ causes status input dropout. A Texas petrochemical plant had intermittent pump status loss until updating the DSTA002B to v6.1. Always match module firmware to CPU firmware (check ABB’s compatibility matrix) and batch update via Control Builder M.

ABB DSTA002B 3BSE018317R1

Technical Deep Dive & Overview

The ABB DSTA002B 3BSE018317R1 is a 16-channel digital status input module engineered for seamless integration with ABB’s AC800M DCS, designed to handle harsh industrial environments. At its core, each channel uses an opto-isolated circuit to separate sensor signals from the DCS backplane, eliminating cross-talk and protecting against voltage transients—critical for refineries and power plants with high electrical noise.

A dedicated 16-bit microcontroller processes input transitions independently per channel, ensuring <5ms response time for time-sensitive applications like safety interlocks. The module converts discrete analog signals (24VDC on/off) to digital data, transmitting it to the AC800M CPU via the DCS backplane at 100ms intervals (configurable down to 10ms).

Unlike generic modules, the DSTA002B requires no hardware jumpers—input type (sinking/sourcing) is configured via software, enabling flexible sensor integration without rewiring. Channel-to-channel isolation (500V AC) blocks electrical interference between channels, a common flaw in budget modules that causes false alarms.

Ruggedization features include a conformal-coated PCB (resisting dust, moisture, and chemical vapors) and a wide operating temperature range, ideal for unconditioned control cabinets. Its ABB-native design ensures plug-and-play integration with AC800M controllers, eliminating custom drivers or scripting. For plants where discrete status reliability directly impacts safety and uptime, this module isn’t just a signal converter—it’s a robust link that ensures trustworthy equipment status data in the harshest industrial conditions.