Description

Key Technical Specifications

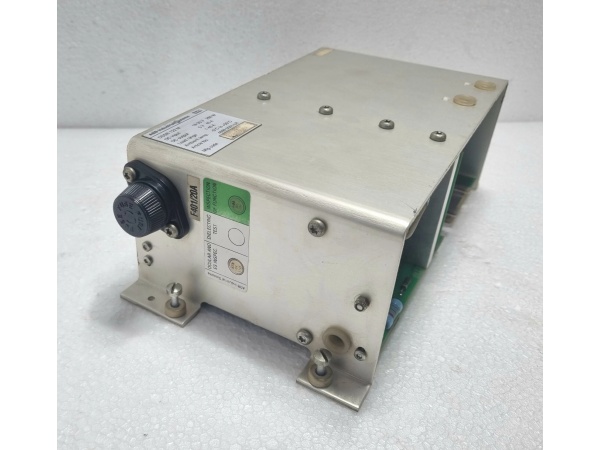

- Model Number: ABB 48990001-LR DSSR122M

- Manufacturer: ABB Power Automation Division

- Channel Configuration: 16 independent solid-state output channels

- Output Technology: MOSFET-based (no mechanical relays), sourcing configuration

- Output Rating: 24VDC ±10%, 2A continuous per channel; 10A total module load

- Switching Time: <1ms (on/off transition), no arcing or contact wear

- Protection Features: Short-circuit (auto-reset), over-temperature shutdown (85°C), reverse polarity protection

- Isolation Rating: 500V AC (channel-to-channel); 1kV AC (outputs to backplane)

- Power Supply: 24VDC from DCS backplane; 0.3A typical current draw

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Compatibility: ABB Symphony Plus DCS, 3BHE series controllers, Control Builder M software

- Mechanical Design: Rack-mount (3U height), conformal-coated PCB, metal housing (IP20)

- Certifications: IEC 61010-1, CE, UL 508, ATEX Zone 2, RoHS 2.0

ABB 48990001-LR DSSR122M

Field Application & Problem Solved

In process automation—refinery valve actuation, power plant boiler feed pumps, chemical reactor agitators—mechanical relay modules fail due to contact wear and heat buildup. A Louisiana refinery lost $110k in a 4-hour outage when a generic mechanical relay module’s contacts welded shut, preventing a critical distillation column valve from closing. Legacy modules also suffer from slow switching: a Pennsylvania power plant’s boiler feed pump control had 50ms lag with mechanical relays, causing pressure fluctuations that reduced efficiency by 3%.

You’ll find this module in Symphony Plus DCS racks driving critical actuators: globe valves in Texas petrochemical plants, boiler feed pumps in Ohio coal plants, and reactor agitators in Minnesota chemical facilities. Its core value is maintenance-free solid-state reliability + fast, precise actuation. The MOSFET design eliminated the Louisiana refinery’s contact wear issues—zero module replacements in 6 years. At the power plant, the <1ms switching time stabilized boiler pressure, boosting efficiency by 2.5%.

For a Florida wastewater treatment plant, the module’s conformal coating withstood corrosive hydrogen sulfide vapors, outlasting uncoated mechanical relay modules by 4x (8 years vs. 2 years). Its channel-to-channel isolation also eliminated cross-talk between pump control circuits, cutting nuisance trips by 90%.

Installation & Maintenance Pitfalls (Expert Tips)

- Channel Loading: Never Exceed 2A Continuous: Rookies drive 3A motors directly through channels, causing MOSFET burnout. A North Carolina chemical plant did this with a 2.5A agitator motor, costing $300 in module repairs and 2 hours of downtime. Use ABB’s 1SBL161001R8001 contactors for loads >2A, and add 2A fuses (1SFA616001R1000) per channel as a backup.

- Heat Dissipation Is Critical: Solid-state modules generate more heat than mechanical relays—ignoring this causes over-temperature shutdowns. A Michigan paper mill stacked I/O modules around the DSSR122M, leading to daily shutdowns during peak load. Maintain 50mm clearance on all sides, avoid mounting near VFDs or power resistors, and use thermal imaging to confirm case temps stay <70°C.

- Wiring Polarity: Sourcing Configuration Only: This module is strictly sourcing (current flows out of the module)—connecting sinking sensors causes no output. A Texas refinery delayed startup by 3 hours due to this mistake. Verify wiring: positive supply to module output terminal, negative to load, and return to common. Test with a multimeter: 24VDC should be present at the load when the channel is active.

- Firmware Mismatch Breaks DCS Communication: Outdated module firmware (pre-v6.2) with Symphony Plus v8.0+ causes output dropout. A Pennsylvania power plant had intermittent valve actuation failures until updating the DSSR122M to v7.1. Always match module firmware to DCS core version (check ABB’s compatibility matrix) and batch update via Control Builder M.

ABB 48990001-LR DSSR122M

Technical Deep Dive & Overview

The ABB 48990001-LR DSSR122M is a 16-channel digital output module engineered for reliable actuation in harsh industrial environments, replacing failure-prone mechanical relays with solid-state MOSFET technology. At its core, each channel uses a rugged power MOSFET that switches 24VDC loads without moving parts, eliminating contact wear, arcing, and welding—common flaws in mechanical relay modules.

A dedicated 16-bit microcontroller monitors each channel’s current and temperature, triggering auto-reset short-circuit protection if load exceeds 2.5A and shutting down channels if temperature exceeds 85°C. Channel-to-channel isolation (500V AC) blocks electrical interference between circuits, a critical feature in power plants and refineries with high EMI.

The module communicates with Symphony Plus controllers via a dedicated backplane link, transmitting output status and fault data in real time. Its <1ms switching time enables precise control of fast-acting valves and pumps, outperforming mechanical relays (20-50ms) by a factor of 20. The conformal-coated PCB resists dust, moisture, and chemical vapors, while the -25°C to +65°C operating range handles unconditioned control cabinets.

What sets it apart from generic solid-state modules is seamless ABB DCS integration—no custom drivers or calibration are needed. It’s factory-calibrated to work with Symphony Plus I/O racks and controllers, reducing commissioning time by 40%. For plants where actuator reliability directly impacts safety and uptime, this module isn’t just a switch—it’s a maintenance-free workhorse that ensures consistent, precise actuation in the harshest industrial conditions.