Description

Detailed parameter table

| Parameter Name | Parameter Value |

| Product Model | ABB DSSB140 |

| Manufacturer | ABB |

| Product Category | High-Density Digital Input Module |

| Input Channels | 32 channels (sink/source configurable) |

| Input Voltage Range | 24 VDC nominal (19.2-30 VDC operational) |

| Input Current | 3 mA per point (typical at 24 VDC) |

| Logic Threshold | 15 VDC ON / 5 VDC OFF |

| Response Time | ≤ 1 ms (ON/OFF state change) |

| Isolation | 1500 VAC channel-to-channel and channel-to-bus |

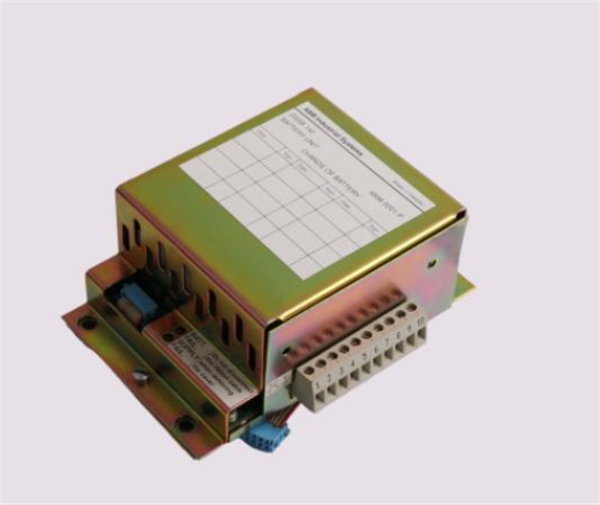

| Connection Type | Removable screw terminal block |

| Compatibility | ABB S800 I/O System (TB820 base unit) |

| Safety Certification | SIL 2 (IEC 61508) with qualified engineering |

| Operating Temperature | -25°C to +70°C (-13°F to +158°F) |

| Power Consumption | 1.8W (5V from controller bus) |

| Diagnostics | Group fault indication (per 8 channels) |

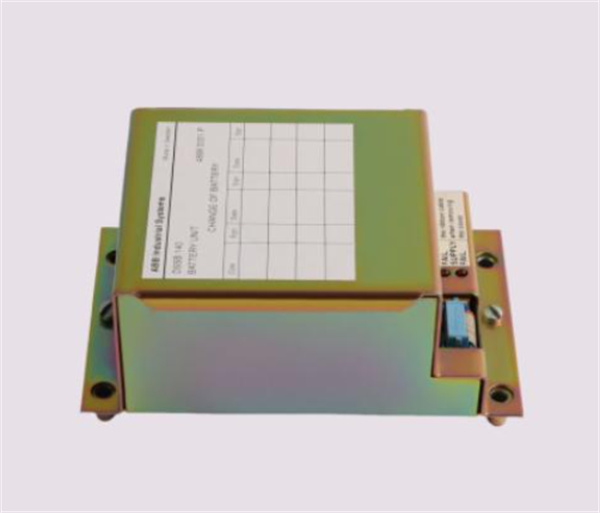

ABB DSSB140

Product introduction

The ABB DSSB140 represents ABB’s high-density solution for digital signal acquisition within its renowned S800 I/O system. Designed as a 32-channel digital input module, this unit serves as a critical interface between field devices (limit switches, pushbuttons, relay contacts) and ABB’s AC 800M controllers. The ABB DSSB140 excels in applications requiring extensive discrete point monitoring while minimizing cabinet space. Its technical design focuses on signal integrity with robust electrical isolation and rapid response times.

Engineered for seamless integration into System 800xA and other ABB control architectures, the ABB DSSB140 provides deterministic data acquisition for process states, equipment status, and interlock conditions. The module’s configurable sink/source capability offers wiring flexibility across global standards. Through its native compatibility with ABB’s TB820 base units and S800 bus, the ABB DSSB140 delivers reliable signal conversion with built-in diagnostics, making it an essential component for scalable control systems in both process and discrete manufacturing environments.

Core advantages and technical highlights

The ABB DSSB140 delivers exceptional value through optimized engineering:

High-Density Efficiency: With 32 channels in a single module slot, the ABB DSSB140 reduces cabinet footprint by up to 60% compared to conventional 16-channel alternatives. This space optimization significantly lowers installation costs while maintaining full diagnostic capability through grouped status indication.

Advanced Signal Integrity: Each channel features 1500 VAC reinforced isolation, eliminating ground loops and preventing noise propagation. The precise 15V ON/5V OFF threshold ensures reliable state detection in electrically noisy environments, even with long cable runs. Gold-plated contacts prevent oxidation for sustained connectivity.

Rapid Response Performance: Engineered for time-critical applications, the ABB DSSB140 achieves sub-millisecond input recognition. This speed is essential for fast-sequence monitoring in packaging machinery, discrete part manufacturing, and safety interlocks where signal latency impacts throughput.

SIL 2 Capable Architecture: When implemented within ABB’s certified safety engineering process, the ABB DSSB140 supports Safety Integrity Level 2 applications. Its design incorporates fault detection mechanisms including input filter monitoring and channel group diagnostics, providing enhanced reliability for safety instrumented functions.

Simplified Maintenance: The module’s front-accessible terminal block allows wiring replacement without disturbing adjacent modules. Clear per-channel LED status indicators accelerate troubleshooting. Hot-swappable capability (in redundant configurations) enables maintenance without process shutdown, while ABB’s Control Builder M software provides detailed diagnostics down to channel level.

Typical application scenarios

The ABB DSSB140 excels in high-I/O-count applications across multiple industries. In automotive manufacturing, 32-channel modules monitor safety door positions, clamp sensors, and tooling status across robotic workcells and assembly stations. The DSSB140‘s density and rapid response enable comprehensive machine state tracking while minimizing control cabinet footprint in space-constrained production lines.

Within material handling systems, the ABB DSSB140 serves as the primary interface for conveyor status networks, tracking photoeye signals, motor-run confirmations, and package presence detection across complex distribution centers. Its robust noise immunity ensures reliable operation near VFD-driven motors. For water treatment plants, the DSSB140 monitors pump seal failure alarms, valve limit switches, and tank level indicators across distributed pumping stations. The module’s SIL 2 capability allows its integration into critical flood control interlock systems, while its wide temperature tolerance supports outdoor cabinet installations.

ABB DSSB140

Related model recommendations

ABB TB820: Mandatory base unit for mounting the DSSB140 in S800 racks.

ABB DI801: 16-channel digital input module (alternative to DSSB140 for lower density needs).

ABB DO810: 16-channel digital output module (complementary to DSSB140 for control signals).

ABB AI845: 8-channel analog input (for process measurement alongside DSSB140).

ABB CI854A: PROFINET interface module (connects DSSB140-equipped racks to networks).

ABB PM803F: Compact AC 800M controller (primary processor for DSSB140 systems).

ABB SD822: SIL 3 digital input module (for safety-critical applications beyond DSSB140‘s SIL 2).

ABB XTIO-008: Remote I/O extension unit (expands DSSB140 deployment range via fiber).

ABB CP635-T: Operator panel (visualizes DSSB140 status in control rooms).

ABB Control Builder M: Configuration software for DSSB140 parameterization and diagnostics.

Installation, commissioning and maintenance instructions

Installation Preparation: Verify cabinet ambient temperature compliance and stable 24V field power. Use ABB-approved TB820 base units mounted on DIN rail. Required tools: torque screwdriver (0.6 Nm for terminals), wire strippers, and ESD protection. Pre-label all field wiring per schematics. Critical precautions: Disconnect controller backplane power before module insertion; ensure correct polarity for sink/source configuration; maintain 10mm clearance above/below module for ventilation; use shielded cables grounded at one end for noise-sensitive applications.

Maintenance Suggestions: Biannually inspect terminal block tightness and check for corrosion. Clean air vents using low-pressure nitrogen. Monitor group fault LEDs monthly and investigate immediately when lit. Replace modules during planned shutdowns: Document wiring, release terminal block latch, slide out DSSB140, insert replacement, and verify channel status in Control Builder M. Maintain firmware synchronization with controller software versions. For persistent channel faults, verify field device voltage and wiring integrity before module replacement.

Service and guarantee commitment

ABB provides an 18-month standard warranty for the ABB DSSB140, covering material and manufacturing defects. Global technical support includes 24/7 access to ABB’s Knowledge Base and emergency hotlines staffed by S800 I/O specialists. Service offerings include:

Configuration assistance and troubleshooting guidance

On-site commissioning support

Firmware update packages with compatibility verification

Repair/exchange programs with 10-day turnaround

Preventive maintenance contracts with health checks

Lifecycle commitment ensures spare availability for 15+ years post-discontinuation. ABB’s warranty extends to SIL 2 applications when installed per safety manuals and validated per IEC 61511 requirements.